Filter by

System of Measurement

Length

Fabrication

Maximum Temperature

Construction

Specifications Met

Hardness

Tolerance Rating

Export Control Classification Number (ECCN)

Minimum Temperature

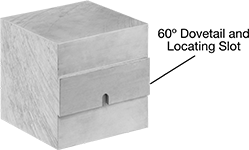

Dovetail Blanks for Milling-Machine Vises

Dovetail | Slots | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Ht. | Angle | No. of | Lg. | Wd. | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6061 Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Wide Dovetail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 3 1/4" | 3 1/4" | 1/8" | 60° | 1 | 13/32" | 9/32" | -320 to 300 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 13/16" | 5 13/16" | 5 13/16" | 1/8" | 60° | 1 | 13/32" | 9/32" | -320 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 1/2" Wide Dovetail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 4" | 4" | 1/8" | 60° | 1 | 15/32" | 9/32" | -320 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 1/4" Wide Dovetail | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 7" | 5" | 3/16" | 60° | 2 | 11/16" | 5/16" | -320 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 10" | 10" | 3/16" | 60° | 2 | 11/16" | 5/16" | -320 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lead Wire

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Dia. Tolerance | Lg., ft. | Fabrication | Heat Treatment | Max. Temp., ° F | Net Wt., lb. | Type | Tensile Strength, psi | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Matte | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | -0.005" to 0.001" | 82 | Heat Treated | Softened | 620 | 5 | Spool | 1,100 | ASTM B29, ASTM B749 | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.125" | -0.005" to 0.001" | 410 | Heat Treated | Softened | 620 | 25 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.188" | -0.005" to 0.001" | 36 | Heat Treated | Softened | 620 | 5 | Spool | 1,100 | ASTM B29, ASTM B749 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.188" | -0.005" to 0.001" | 180 | Heat Treated | Softened | 620 | 25 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | -0.005" to 0.001" | 20 | Heat Treated | Softened | 620 | 5 | Spool | 1,100 | ASTM B29, ASTM B749 | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.25" | -0.005" to 0.001" | 100 | Heat Treated | Softened | 620 | 25 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.375" | -0.01" to 0.015" | 92 | Heat Treated | Softened | 620 | 50 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.5" | -0.01" to 0.015" | 51 | Heat Treated | Softened | 620 | 50 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.75" | -0.01" to 0.015" | 23 | Heat Treated | Softened | 620 | 50 | Spool | 1,100 | ASTM B29, ASTM B749 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shape-Memory Nitinol Wire

Coils

Dia. | Dia. Tolerance | Lg., ft. | Finish | Max. Temp., ° F | Heat Treatment | Tensile Strength, psi | Specs. Met | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.003" | -0.0001" to 0.0001" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 000000 | |

| 0.005" | -0.0002" to 0.0002" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 000000 | 00000 | |

| 0.01" | -0.0003" to 0.0003" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 000000 | 00000 | |

| 0.02" | -0.0004" to 0.0004" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 000000 | 00000 | |

| 0.025" | -0.0005" to 0.0005" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 00000 | |

| 0.03" | -0.0005" to 0.0005" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 000000 | 00000 | |

| 0.04" | -0.0008" to 0.0008" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 000000 | |

| 0.05" | -0.001" to 0.001" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 000000 | |

| 0.06" | -0.001" to 0.001" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 000000 | |

| 0.08" | -0.001" to 0.001" | 30 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 00000000 | 000000 |

Packages

Dia. | Dia. Tolerance | Lg., ft. | Finish | Max. Temp., ° F | Heat Treatment | Tensile Strength, psi | Specs. Met | Pkg. Qty. | Pkg. | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.003" | -0.0001" to 0.0001" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 00000 | |

| 0.005" | -0.0002" to 0.0002" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 0000 | |

| 0.01" | -0.0003" to 0.0003" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 00000 | |

| 0.02" | -0.0004" to 0.0004" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 00000 | |

| 0.025" | -0.0005" to 0.0005" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 00000 | |

| 0.03" | -0.0008" to 0.0008" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 00000 | |

| 0.04" | -0.0008" to 0.0008" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 000000 | |

| 0.05" | -0.001" to 0.001" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 000000 | |

| 0.06" | -0.001" to 0.001" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 000000 | |

| 0.08" | -0.001" to 0.001" | 2 | Black Oxide | 250 | Softened | 157,500 | ASTM F2063 | 5 | 00000000 | 000000 |