Filter by

System of Measurement

Material

Ball Material

Shape

Hardness Rating

Hardness

Appearance

Performance

Heat Treatment

Magnetic Properties

Maximum Temperature

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Construction

REACH

RoHS

Minimum Temperature

Yield Strength

Mount Type

Thread Size

About Stainless Steel

Compare over 25 types of stainless steel to find the right material for you—all with material certificates for traceability.

Stainless Steel Balls

|

Dia., mm | Dia. Tolerance, mm | Fabrication | Hardness | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Tight-Tolerance 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 50 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 50 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 50 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | -0.0127 to 0.0127 | Cold Worked | Rockwell C25 (Hard) | ASTM A240, ISO 3290, SAE J405 | 10 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 250 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 250 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.5 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 100 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 50 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | -0.013 to 0.013 | — | Rockwell C25 (Hard) | — | 10 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hardened 440C Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.5 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.5 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 250 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.5 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 100 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 50 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 50 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 50 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 25 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 5 | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 3 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | -0.0025 to 0.0025 | — | Rockwell C60 (Extra Hard) | — | 3 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clean Room Stud-Mount Ball Transfers

Temp., ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

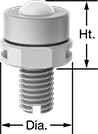

Ball Dia. | Wt. Cap., lb. | Ht. | Dia. | Working Orientation | Housing Color | Thread Size | Stud Lg. | Min. | Max. | Clean Room Std. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2 1/2 | 9/16" | 19/32" | Ball Up | Beige | M8 × 1.25 mm | 15/32" | 0 | 260 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vespel® Polyimide/Stainless Steel Housing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1 | 9/16" | 19/32" | Ball Up | Brown | M8 × 1.25 mm | 15/32" | 0 | 200 | Fed. Std. Class 1,000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||