About Moment Loads

More

About Magnification

More

Positioning Tables with Micrometer

The micrometer handles ensure accurate, repeatable positioning along a single axis—good for positioning parts, such as measuring and inspecting equipment, that are part of a larger automated system.

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg. | Wd. | Lg. | Ht. | Wd. | Lg. | Handle Dia. | Micrometer Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 0.5" | 1.25" | 3.25" | 0.38" | 1.25" | 1.25" | 0.41" | 0.001" | 180° | 10 | 2-56 | 4 | 2-56 | No | 00000000 | 0000000 |

| 12 | 0.5" | 1.5" | 3.5" | 0.62" | 1.5" | 1.5" | 0.41" | 0.001" | 180° | 4 | 4-40 | 2 | 4-40 | No | 00000000 | 000000 |

| 20 | 0.5" | 1.75" | 4.38" | 0.75" | 1.75" | 1.75" | 0.54" | 0.001" | 180° | 6 | 6-32 | 2 | 6-32 | No | 00000000 | 000000 |

| 20 | 1" | 1.75" | 5.88" | 0.75" | 1.75" | 1.75" | 0.7" | 0.001" | 180° | 6 | 6-32 | 2 | 6-32 | No | 00000000 | 000000 |

| 30 | 2" | 4.12" | 10.25" | 0.91" | 4.12" | 4.12" | 0.83" | 0.001" | 180° | 10 | 10-32 | 2 | 10-32 | No | 00000000 | 000000 |

| 60 | 1" | 2.62" | 6.75" | 1" | 2.62" | 2.62" | 0.72" | 0.001" | 180° | 8 | 10-32 | 2 | 10-32 | No | 00000000 | 000000 |

| 100 | 1" | 5" | 9.31" | 1" | 5" | 5" | 0.7" | 0.001" | 155° | 12 | 1/4"-20 | 2 | 1/4"-20 | No | 0000000 | 000000 |

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg., mm | Wd., mm | Lg., mm | Ht., mm | Wd., mm | Lg., mm | Handle Dia., mm | Micrometer Graduation Marks, mm | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 13 | 31.8 | 82.6 | 9.7 | 31.8 | 31.8 | 10.4 | 0.01 | 180° | 10 | M2 | 4 | M2 | No | 00000000 | 0000000 |

| 4 | 13 | 44.5 | 95.3 | 9.7 | 44.5 | 44.5 | 10.4 | 0.01 | 180° | 10 | M2 | 4 | M2 | No | 00000000 | 000000 |

| 20 | 25 | 44.5 | 149.4 | 19.1 | 44.5 | 44.5 | 17.8 | 0.01 | 180° | 6 | M4 | 2 | M4 | No | 00000000 | 000000 |

| 30 | 50 | 104.6 | 260.4 | 23.1 | 104.6 | 104.6 | 21.1 | 0.01 | 180° | 10 | M5 | 2 | M5 | No | 00000000 | 000000 |

| 60 | 13 | 66.5 | 133.4 | 25.4 | 66.5 | 66.5 | 13.2 | 0.01 | 180° | 8 | M5 | 2 | M5 | No | 00000000 | 000000 |

Locking Positioning Tables with Micrometer

A knurled knob locks the slide without affecting its position. The micrometer handles ensure accurate, repeatable positioning along a single axis—good for positioning parts, such as measuring and inspecting equipment, that are part of a larger automated system.

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg. | Wd. | Lg. | Ht. | Wd. | Lg. | Handle Dia. | Micrometer Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 0.5" | 1.475" | 3.25" | 0.38" | 1.25" | 1.25" | 0.425" | 0.001" | 180° | 10 | 2-56 | 4 | 2-56 | No | 0000000 | 0000000 |

| 6 | 0.5" | 1.63" | 3.34" | 0.5" | 1.25" | 1.28" | 0.55" | 0.001" | 155° | 6 | 4-40 | 2 | 4-40 | No | 0000000 | 000000 |

| 20 | 0.5" | 2" | 4.62" | 0.75" | 1.75" | 2" | 0.545" | 0.001" | 180° | 8 | 6-32 | 2 | 6-32 | No | 0000000 | 000000 |

| 25 | 0.5" | 2.13" | 4.47" | 0.75" | 1.75" | 1.75" | 0.55" | 0.001" | 155° | 8 | 6-32 | 2 | 6-32 | No | 0000000 | 000000 |

| 30 | 1" | 3.12" | 7.419" | 0.91" | 3.12" | 3.12" | 0.72" | 0.001" | 180° | 10 | 10-32 | 2 | 10-32 | No | 00000000 | 000000 |

| 60 | 1" | 3" | 6.94" | 1" | 2.62" | 2.62" | 0.7" | 0.001" | 155° | 8 | 10-32 | 2 | 1/4"-20 | No | 0000000 | 000000 |

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg., mm | Wd., mm | Lg., mm | Ht., mm | Wd., mm | Lg., mm | Handle Dia., mm | Micrometer Graduation Marks, mm | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 5 | 6 | 25 | 57.9 | 13.5 | 19.1 | 19.1 | 10 | 0.01 | 180° | 8 | M2 | 4 | M2 | No | 00000000 | 0000000 |

| 20 | 25 | 50.6 | 149.4 | 19.1 | 44.5 | 44.5 | 18.5 | 0.01 | 180° | 6 | M4 | 2 | M4 | No | 0000000 | 000000 |

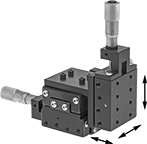

Locking Two-Axis Positioning Tables with Micrometers

A knurled knob locks the slide without affecting its position. The micrometer handles ensure accurate, repeatable positioning along two axes—good for positioning parts, such as measuring and inspecting equipment, that are part of a larger automated system.

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg. | Wd. | Lg. | Ht. | Wd. | Lg. | Handle Dia. | Micrometer Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 0.5" | 3.48" | 3.25" | 0.76" | 1.25" | 1.25" | 0.42" | 0.001" | 180° | 10 | 2-56 | 4 | 2-56 | No | 00000000 | 0000000 |

| 6 | 0.5" | 3.72" | 3.34" | 1" | 1.25" | 1.28" | 0.55" | 0.001" | 155° | 6 | 4-40 | 2 | 4-40 | No | 0000000 | 00000000 |

| 20 | 1" | 6.12" | 5.88" | 1.5" | 1.75" | 1.75" | 0.71" | 0.001" | 180° | 6 | 6-32 | 2 | 6-32 | No | 00000000 | 000000 |

| 25 | 0.5" | 4.85" | 4.47" | 1.5" | 1.75" | 1.75" | 0.55" | 0.001" | 155° | 8 | 6-32 | 2 | 6-32 | No | 0000000 | 00000000 |

| 60 | 1" | 7.32" | 6.94" | 2" | 2.62" | 2.62" | 0.7" | 0.001" | 155° | 8 | 10-32 | 2 | 1/4"-20 | No | 0000000 | 00000000 |

O'all | Carriage | Carriage Mounting | Base Mounting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg., mm | Wd., mm | Lg., mm | Ht., mm | Wd., mm | Lg., mm | Handle Dia., mm | Micrometer Graduation Marks, mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | |||||||||||||||||

| 5 | 6 | 57.9 | 57.9 | 26.9 | 19.1 | 19.1 | 9.4 | 0.01 | 180° | 8 | M2 | 0.4 | 4 | M2 | No | 00000000 | 0000000 |

Two-Axis Positioning Tables with Micrometers

The micrometer handles ensure accurate, repeatable positioning along two axes—good for positioning parts, such as measuring and inspecting equipment, that are part of a larger automated system.

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg. | Wd. | Lg. | Ht. | Wd. | Lg. | Handle Dia. | Micrometer Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 0.5" | 3.25" | 3.25" | 0.75" | 1.25" | 1.25" | 0.41" | 0.001" | 180° | 10 | 2-56 | 4 | 2-56 | No | 00000000 | 0000000 |

| 12 | 0.5" | 3.5" | 3.5" | 1.25" | 1.5" | 1.5" | 0.41" | 0.001" | 180° | 4 | 4-40 | 2 | 4-40 | No | 00000000 | 000000 |

| 20 | 0.5" | 4.38" | 4.38" | 1.5" | 1.75" | 1.75" | 0.54" | 0.001" | 180° | 6 | 6-32 | 2 | 6-32 | No | 00000000 | 000000 |

| 20 | 1" | 6" | 6" | 1.5" | 1.75" | 1.75" | 0.7" | 0.001" | 180° | 6 | 6-32 | 2 | 6-32 | No | 00000000 | 000000 |

| 30 | 2" | 10.25" | 10.25" | 1.82" | 4.12" | 4.12" | 0.7" | 0.001" | 180° | 10 | 10-32 | 2 | 10-32 | No | 00000000 | 00000000 |

| 60 | 1" | 6.88" | 6.88" | 2" | 2.62" | 2.62" | 0.7" | 0.001" | 180° | 8 | 10-32 | 2 | 10-32 | No | 00000000 | 000000 |

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg., mm | Wd., mm | Lg., mm | Ht., mm | Wd., mm | Lg., mm | Handle Dia., mm | Micrometer Graduation Marks, mm | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 4 | 13 | 82.6 | 82.6 | 19 | 31.8 | 31.8 | 10.4 | 0.01 | 180° | 10 | M2 | 4 | M2 | No | 000000000 | 0000000 |

| 12 | 13 | 88.9 | 88.9 | 31.8 | 38.1 | 38.1 | 10.4 | 0.01 | 180° | 4 | M3 | 2 | M3 | No | 000000000 | 000000 |

| 20 | 25 | 149.4 | 149.4 | 38.1 | 44.5 | 44.5 | 17.8 | 0.01 | 180° | 6 | M4 | 2 | M4 | No | 000000000 | 000000 |

| 30 | 50 | 285.8 | 285.8 | 46.2 | 130.2 | 130.2 | 17.8 | 0.01 | 180° | 10 | M5 | 2 | M5 | No | 000000000 | 00000000 |

| 60 | 25 | 171.5 | 171.5 | 50.8 | 66.5 | 66.5 | 17.8 | 0.01 | 180° | 8 | M5 | 2 | M5 | No | 000000000 | 000000 |

Three-Axis Positioning Tables with Micrometers

The micrometer handles ensure accurate, repeatable positioning along three axes—good for positioning parts, such as measuring and inspecting equipment, that are part of a larger automated system.

O'all | Carriage | Carriage Mounting | Base Mounting | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg. | Wd. | Lg. | Ht. | Wd. | Lg. | Handle Dia. | Micrometer Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | ||||||||||||||||

| 1 | 0.5" | 3.25" | 3.63" | 3.87" | 1.25" | 1.25" | 0.42" | 0.001" | 180° | 10 | 2-56 | 4 | 2-56 | No | 0000000 | 0000000 |

| 20 | 0.5" | 4.62" | 5.74" | 5.12" | 1.75" | 2" | 0.54" | 0.001" | 180° | 8 | 6-32 | 2 | 6-32 | No | 0000000 | 000000 |

| 30 | 1" | 7.25" | 7.25" | 9.83" | 3.12" | 3.12" | 0.71" | 0.001" | 180° | 10 | 10-32 | 2 | 10-32 | No | 0000000 | 00000000 |

| 30 | 2" | 10.25" | 10.25" | 13.33" | 4.12" | 4.12" | 0.62" | 0.001" | 180° | 10 | 10-32 | 2 | 10-32 | No | 0000000 | 00000000 |

O'all | Carriage | Carriage Mounting | Base Mounting | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Static Load Cap., lbs. | Travel Lg., mm | Wd., mm | Lg., mm | Ht., mm | Wd., mm | Lg., mm | Handle Dia., mm | Micrometer Graduation Marks, mm | Max. Temp., °F | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | |||||||||||||||||

| 1 | 13 | 82.6 | 92.3 | 98.3 | 31.8 | 31.8 | 10.7 | 0.01 | 180° | 10 | M2 | 0.4 | 4 | M2 | No | 00000000 | 0000000 |

| 20 | 13 | 117.3 | 145.7 | 130 | 44.5 | 50.8 | 13.6 | 0.01 | 180° | 8 | M4 | 0.7 | 2 | M4 | No | 00000000 | 000000 |

| 30 | 25 | 184.2 | 184.2 | 249.7 | 79.2 | 79.2 | 18 | 0.01 | 180° | 10 | M5 | 0.8 | 2 | M5 | No | 00000000 | 00000000 |

| 30 | 50 | 260.4 | 260.4 | 338.6 | 104.6 | 104.6 | 15.8 | 0.01 | 180° | 10 | M5 | 0.8 | 2 | M5 | No | 00000000 | 00000000 |

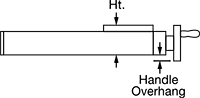

Precision Positioning Slides

A linear scale and micrometer-like hand wheel measure travel distance in increments of 0.001". Rulon sleeve bearings allow these slides to move smoothly, even in dirty environments. Use them in a variety of manual-positioning applications for laboratory and production equipment as well as for positioning parts for drilling, fastening, assembly, and measuring.

Travel distance per turn, also known as screw lead, is the distance the carriage moves with one revolution of the handle.

Note: Capacities listed are for horizontal mounting. When mounted vertically, the load capacity is cut in half.

O'all | Carriage | Handle | Carriage Mounting | Base Mounting | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Travel Lg. | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Ht. | Wd. | Lg. | Wd. | Lg. | Type | Dia. | Overhang | Linear Scale Graduation Marks | Max. Temp., °F | No. of Holes | Hole Thread Size | No. of Holes | For Fastener Thread Size | Mounting Fasteners Included | Each | |

Aluminum Carriage and Base | |||||||||||||||||||

15 lbs. Static Load Capacity | |||||||||||||||||||

| 1.5" | 0.05" | 0.00015" per in. | 0.61" | 1.5" | 5.6" | 0.62" | 1.5" | Hand Wheel | 1.75" | 0.59" | 0.025" | 180° | 4 | 6-32 | 2 | 8-32 | No | 0000000 | 0000000 |

| 4.5" | 0.05" | 0.00015" per in. | 0.56" | 1.5" | 8.6" | 0.62" | 1.5" | Hand Wheel | 1.75" | 0.59" | 0.025" | 180° | 4 | 6-32 | 2 | 8-32 | No | 0000000 | 000000 |

| 7.5" | 0.05" | 0.00015" per in. | 0.61" | 1.5" | 11.6" | 0.62" | 1.5" | Hand Wheel | 1.75" | 0.59" | 0.025" | 180° | 4 | 6-32 | 3 | 8-32 | No | 0000000 | 000000 |

| 10.5" | 0.05" | 0.00015" per in. | 0.61" | 1.5" | 14.6" | 0.62" | 1.5" | Hand Wheel | 1.75" | 0.59" | 0.025" | 180° | 4 | 6-32 | 4 | 8-32 | No | 0000000 | 000000 |

30 lbs. Static Load Capacity | |||||||||||||||||||

| 1.5" | 0.05" | 0.00015" per in. | 0.81" | 2.5" | 6.74" | 1.25" | 2.5" | Hand Wheel | 1.75" | 0.44" | 0.025" | 180° | 4 | 8-32 | 2 | 10-32 | No | 0000000 | 000000 |

| 3.5" | 0.05" | 0.00015" per in. | 0.81" | 2.5" | 8.74" | 1.25" | 2.5" | Hand Wheel | 1.75" | 0.44" | 0.025" | 180° | 4 | 8-32 | 2 | 10-32 | No | 0000000 | 000000 |

| 6.5" | 0.05" | 0.00015" per in. | 0.81" | 2.5" | 11.74" | 1.25" | 2.5" | Hand Wheel | 1.75" | 0.44" | 0.025" | 180° | 4 | 8-32 | 3 | 10-32 | No | 0000000 | 000000 |

100 lbs. Static Load Capacity | |||||||||||||||||||

| 2" | 0.1" | 0.00015" per in. | 1.06" | 4" | 9.41" | 2.35" | 4" | Hand Wheel | 1.75" | 0.24" | 0.025" | 180° | 4 | 10-32 | 2 | 1/4"-20 | No | 0000000 | 000000 |

| 5" | 0.1" | 0.00015" per in. | 1.06" | 4" | 12.41" | 2.35" | 4" | Hand Wheel | 1.75" | 0.24" | 0.025" | 180° | 4 | 10-32 | 3 | 1/4"-20 | No | 0000000 | 00000000 |

| 8" | 0.1" | 0.00015" per in. | 1.06" | 4" | 15.41" | 2.35" | 4" | Hand Wheel | 1.75" | 0.24" | 0.025" | 180° | 4 | 10-32 | 4 | 1/4"-20 | No | 0000000 | 00000000 |

| 11" | 0.1" | 0.00015" per in. | 1.06" | 4" | 18.41" | 2.35" | 4" | Hand Wheel | 1.75" | 0.24" | 0.025" | 180° | 4 | 10-32 | 5 | 1/4"-20 | No | 0000000 | 00000000 |

| 14" | 0.1" | 0.00015" per in. | 1.06" | 4" | 21.41" | 2.35" | 4" | Hand Wheel | 1.75" | 0.24" | 0.025" | 180° | 4 | 10-32 | 6 | 1/4"-20 | No | 0000000 | 00000000 |

Miniature Ball Bearing Carriages and Guide Rails

These tiny carriages and guide rails are sized for electronic and other precision applications. They come furnished as a complete unit (a carriage on a guide rail). Mount in any orientation without affecting load capacity.

Note: Ball bearings do not have a cage, so they’ll fall out if the carriage is removed from the guide rail.

Mount 1 mm wd. rails with mounting brackets (sold separately; order one for each end of the guide rail).

Carriage Mounting | Guide Rail Mounting | 440 Stainless Steel Carriages and Guide Rails | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Rail Lg., mm | Rail Ht., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Depth, mm | Fasteners Included | No. of Holes | For Fastener Thread Size | Hole Depth, mm | Fasteners Included | Each | |

Load Fastening From Top | |||||||||||||||||

| 1 | 42 | 1.4 | 15 | 2.5 | 4 | 6.5 | 2 | M1 | 0.25 | 0.9 | No | __ | __ | __ | __ | 0000000 | 0000000 |

| 1 | 84 | 1.4 | 15 | 2.5 | 4 | 6.5 | 2 | M1 | 0.25 | 0.9 | No | __ | __ | __ | __ | 0000000 | 000000 |

| 2 | 32 | 2 | 45 | 3.2 | 6 | 12.4 | 2 | M1.4 | 0.3 | 1.1 | No | 4 | M1 | 2 | No | 0000000 | 000000 |

| 2 | 40 | 2 | 45 | 3.2 | 6 | 12.4 | 2 | M1.4 | 0.3 | 1.1 | No | 5 | M1 | 2 | No | 000000 | 000000 |

| 2 | 56 | 2 | 45 | 3.2 | 6 | 12.4 | 2 | M1.4 | 0.3 | 1.1 | No | 7 | M1 | 2 | No | 0000000 | 000000 |

| 2 | 80 | 2 | 45 | 3.2 | 6 | 12.4 | 2 | M1.4 | 0.3 | 1.1 | No | 10 | M1 | 2 | No | 000000 | 000000 |

| 3 | 40 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 4 | M1.6 | 2.6 | No | 0000000 | 000000 |

| 3 | 60 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 6 | M1.6 | 2.6 | No | 000000 | 000000 |

| 3 | 80 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 8 | M1.6 | 2.6 | No | 0000000 | 000000 |

| 3 | 100 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 10 | M1.6 | 2.6 | No | 000000 | 000000 |

| 4 | 40 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 4 | M1.6 | 1.85 | Yes | 0000000 | 000000 |

| 4 | 70 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 7 | M1.6 | 1.85 | Yes | 0000000 | 000000 |

| 4 | 100 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 10 | M1.6 | 1.85 | Yes | 0000000 | 000000 |

| 6 | 60 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 4 | M2 | 1.3 | Yes | 0000000 | 000000 |

| 6 | 90 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 6 | M2 | 1.3 | Yes | 0000000 | 000000 |

| 6 | 120 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 8 | M2 | 1.3 | Yes | 0000000 | 000000 |

| Lg., mm | Ht., mm | Wd., mm | Material | For Mounting Fastener Thread Size | Mounting Hole Center-to-End, mm | Mounting Fasteners Included | Each | |

| 7 | 2.4 | 3 | Steel | M1.6 | 3.5 | No | 000000 | 000000 |

Anti-Reflective Miniature Ball Bearing Carriages and Guide Rails

Small enough to fit in a camera zoom lens and other precision motion applications, these carriages and guide rails have a black chrome-plated finish that diffuses light to prevent reflecting light from causing equipment to malfunction. They are also useful in positioning systems that use photosensors, which are sensitive to light. The finish gives you two times more rust resistance than 440 stainless steel alone. The carriage comes already installed on the guide rail. However, the ball bearings don’t have a cage, so they’ll fall out if you remove the carriage from the guide rail. Mount them in any orientation without affecting load capacity.

Carriage Mounting | Guide Rail Mounting | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Rail Wd., mm | Rail Lg., mm | Rail Ht., mm | Dynamic Load Cap., lbs. | O'all Ht., mm | Carriage Wd., mm | Carriage Lg., mm | No. of Holes | Hole Thread Size | Hole Thread Pitch, mm | Hole Depth, mm | Fasteners Included | No. of Holes | For Fastener Thread Size | Hole Depth, mm | Fasteners Included | Grease Fitting Included | Each | |

Load Fastening From Top | ||||||||||||||||||

Black Chrome-Plated 440 Stainless Steel Carriages with Black Chrome-Plated 440 Stainless Steel Guide Rails | ||||||||||||||||||

| 3 | 40 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 4 | M1.6 | 2.6 | No | Yes | 0000000 | 0000000 |

| 3 | 60 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 6 | M1.6 | 2.6 | No | __ | 0000000 | 000000 |

| 3 | 80 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 8 | M1.6 | 2.6 | No | __ | 0000000 | 000000 |

| 3 | 100 | 2.6 | 75 | 4 | 8 | 15.5 | 2 | M2 | 0.4 | 1.3 | No | 10 | M1.6 | 2.6 | No | __ | 0000000 | 000000 |

| 4 | 40 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 4 | M1.6 | 1.85 | Yes | __ | 0000000 | 000000 |

| 4 | 70 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 7 | M1.6 | 1.85 | Yes | __ | 0000000 | 000000 |

| 4 | 100 | 2.6 | 85 | 4 | 10 | 17 | 2 | M2 | 0.4 | 1.3 | No | 10 | M1.6 | 1.85 | Yes | __ | 0000000 | 000000 |

| 6 | 60 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 4 | M2 | 1.3 | Yes | __ | 0000000 | 000000 |

| 6 | 90 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 6 | M2 | 1.3 | Yes | __ | 0000000 | 000000 |

| 6 | 120 | 2.8 | 95 | 4.5 | 12 | 20 | 2 | M2 | 0.4 | 1.6 | No | 8 | M2 | 1.3 | Yes | __ | 0000000 | 000000 |

Microscope Slides

| Ht., mm | Wd., mm | Thick., mm | Material | Pkg. Qty. | Pkg. | |

| 25 | 75 | 1 | Glass | 72 | 0000000 | 000000 |