5-Axis Tabletop CNC Milling Machines

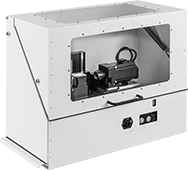

With a tilting, rotating table, these milling machines create more complex shapes than 3-axis models without requiring multiple setups. By moving the spindle and rotating the workpiece simultaneously, they’re capable of making helical gears, manifolds, and other small parts that require 3D contouring, hollowing, and undercutting. Similar in size to a desktop printer, they mill plastic, wood, and soft metal pieces up to 4.55" × 5" × 3.55" for rapid prototyping of small-parts; however, they’re not for production-scale work. They are compatible with 2D and 3D CAD files.

Machines move on five axes: the spindle travels 4.55" side to side; the table travels 5" front to back, 3.55" up and down, tilts 160°, and rotates 360°. They have a 200W brushless DC motor that powers the spindle up to 10,000 rpm with 0.002" of TIR (total indicated runout). TIR is a measure of rotational smoothness—the lower the value, the less wobble a rotating tool will have, and the more accurate it will be.

All have a single-flute, carbide square end mill for making square slots, pockets, and edges. A tool length measurement device ensures accurate cuts, even when switching tools. A steel enclosure contains chips and reduces noise.

Machines include a 1/8" ER-11 collet for holding round-shank tools, such as router bits, drill bits, and end mills, with shank sizes from 0.109" to 1/8". Use additional ER-11 collets to hold tools that have larger shank sizes.

Edge finders with holder mount directly into the spindle. They locate edges, shoulders, center points, and lines on your workpiece.

ER-40 collets with adapters fit inside the hole in the center of the machine’s table to hold round workpieces. Because the workpiece passes through the table, it allows clearance for machining longer pieces.

Tool holder sets include three extended tool holders, one standard tool holder, and a stand to hold all four. Standard tool holders are for tools that are longer than 2 1/2"; extended tool holders are for tools that are 2 1/2" in length and shorter.

Overall | Max. Workpiece | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | Wt., lbs. | For Collet Type | Spindle Speed, rpm | Frame Material | Enclosure Material | TIR (Total Indicated Runout) Accuracy | Features | Includes | Each | |

| 17 1/2" | 23" | 11 1/2" | 4.55" | 5" | 3.55" | 37 | ER-11 | 2,000-10,000 | Aluminum | Steel | 0.002" | Tool Length Measurement Device | Enclosure, USB Cable, 1/8" Carbide Square End Mill, 1/8" ER-11 Collet, Collet Wrench, Tool Holder, Vise | 0000000 | 000000000 |

Torque, in.-lbs. | Insulation | O'all | Shaft | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Speed, rpm | Voltage | Full Load Current, A | Wattage, kW | Frame Size | Max. | Continuous | Class | Max. Temp., °F | Lg. | Wd. | Ht. | Dia., mm | Lg., mm | TIR (Total Indicated Runout) Accuracy | Collet Type | Collet Sizes Included | Each | |

| 14,400 | 48V DC | 24.9 | 0.211 | NEMA 24 | 0.31 | 0.1 | F | 311° | 5.3" | 2.4" | 2.4" | 7 | 20 | 0.0005" | ER-11 | 1/8" | 0000000 | 0000000 |

| Collet Size | Grip Range | Workpiece Dia. Tolerance | Max. Body Dia. | Overall Lg. | Material | Approximate Dia. Compression | Each | |

| 1/8" | 0.109"-0.125" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 000000 |

| 3/16" | 0.172"-0.187" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 00000 |

| 1/4" | 0.234"-0.250" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 00000 |

| Edge Finder Body Dia. | Tip Dia. | Material | Each | |

| 3/8" | 0.2" | Steel | 0000000 | 0000000 |

Collet | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Material | For Dia. | Overall Lg. | OD | Material | Includes | Each | |

| 1" | Steel | 1/8"-1 1/8" (3 mm-28 mm) | 1.15" | 2.09" | Aluminum | ER-40 Wrench | 0000000 | 0000000 |

| For Number of Tools | For Max. Tool Size | Material | Includes | Each | |

| 5 | 1/4" | Aluminum | One Stand, One Standard Tool Holder, Three Extended Tool Holders | 0000000 | 0000000 |

3-Axis Tabletop CNC Milling Machines

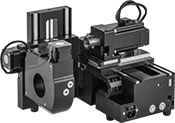

Design and machine small parts for rapid prototyping. Similar in size to a desktop printer, these CNC machines mill plastic, wood, copper, aluminum, and other soft metals up to 8" × 8" × 3". Compared to manual milling machines, they are faster, more consistent, and able to create more complex shapes; however, they are not for production-scale work. Use them for milling contoured 3D objects, printed circuit boards (PCBs), and small parts such as gears, retaining rings, and shims. They are compatible with 2D and 3D CAD files and include software for creating 2D designs from scratch, no experience required.

Machines move on three axes: the spindle travels 8" side to side and 3" up and down; the table travels 8" front to back. They have a 130W brushless DC motor that powers the spindle up to 24,000 rpm with 0.0001" of TIR (total indicated runout). TIR is a measure of rotational smoothness—the lower the value, the less wobble a rotating tool will have, and the more accurate it will be.

All include one square end mill for making square slots, pockets, and edges and one ball end mill for making rounded slots, slopes, and contours. A tool length measurement device ensures accurate cuts, even when switching tools. A 1/2" MDF wasteboard protects the end mill from damage, similar in principle to a kitchen cutting board. The built-in enclosure contains chips and reduces noise.

Machines also include a 1/8" ER-11 collet for holding round-shank tools, such as router bits, drill bits, and end mills, with shank sizes from 0.109" to 1/8". Use additional ER-11 collets to hold tools that have larger shank sizes.

Flip jigs attach to the table and hold the workpiece in place to save time and prevent mistakes when machining both sides of the workpiece. When one side is done, turn the jig over and the other side is already in place, no edge-finders or recalibration needed.

Fixture plates have an array of M6 × 1 mm threaded holes to support various clamps and workholding setups. Attach the fixture plate to the machine’s table using the included fasteners.

Vises firmly hold the workpiece for precise machining. They are sized to fit the machine’s table; attach with the included fasteners.

Overall | Max. Workpiece | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Ht. | Wd. | Dp. | Wt. | For Collet Type | Spindle Speed | Frame Material | Enclosure Material | TIR (Total Indicated Runout) Accuracy | Features | Includes | Each | |

| 17" | 17 1/2" | 19" | 3" | 8" | 8" | 60 lbs. | ER-11 | 9,000 rpm-24,000 rpm | Aluminum | Wood | 0.0001" | Enclosure, Lights, Tool Length Measurement Device | Carbide Create (2D CAD/CAM) Software, MeshCAM (3D CAM) Software, USB Cable, 1/8" Carbide Square End Mill, 1/8" ER-11 Collet, Collet Wrench, 1/2" MDF Wasteboard, 1/8" Carbide Round End Mill, BitZero 2.0 Probe, Alibre (3D CAD/CAM) Software, Spindle Wrench | 000000 | 000000000 |

| Collet Size | Grip Range | Workpiece Dia. Tolerance | Max. Body Dia. | Overall Lg. | Material | Approximate Dia. Compression | Each | |

| 1/8" | 0.109"-0.125" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 000000 |

| 3/16" | 0.172"-0.187" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 00000 |

| 1/4" | 0.234"-0.250" | -0.0001" to 0.0001" | 0.46" | 0.71" | Steel | 1/64" | 0000000 | 00000 |

Max. Workpiece | ||||||

|---|---|---|---|---|---|---|

| Wd. | Dp. | Ht. | Material | Mounting Hardware Included | Each | |

| 5" | 1.2" | 3" | Aluminum | Yes | 000000 | 0000000 |

| Lg. | Wd. | Thick. | Number of Holes | Hole Size | Material | Mounting Hardware Included | Each | |

| 8" | 8" | 1/2" | 85 | M6 | Aluminum | Yes | 000000 | 0000000 |

| Lg. | Wd. | Max. Jaw Opening | Material | Mounting Hardware Included | Each | |

| 8" | 2" | 6 1/2" | Aluminum | Yes | 000000 | 0000000 |

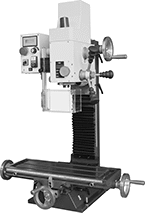

Bench-Top Manual Milling Machines

Compact but powerful, these machines can mill, drill, tap, bore, and more. Since they fit on a workbench, they’re a good choice for job shops, maintenance departments, and other multipurpose spaces. The table is cast iron for strength and stability, and they have heavy duty tapered roller bearings. A digital readout displays real-time tool positioning along two axes for increased machining accuracy.

Workbenches are made of steel and sized for these milling machines.

Overall | Max. Workpiece | Spindle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Ht. | Dp. | No. of Axes | Wt., lbs. | Speed, rpm | Morse Taper No. | Travel | TIR (Total Indicated Runout) Accuracy | Features | Includes | Each | |

120V DC—1 1/5 hp Brushless Motor | ||||||||||||||

| 34" | 27" | 22" | 13" | 7" | 2 | 230 | 90-3,000 | 2 | 1 31/32" | 0.0005" | Built-In Worklight (Bulb included), Drilling Depth Digital Readout, Safety Guard, Spindle Speed Digital Readout | Depth Stop, Tool Holder | 00000000 | 000000000 |

Machine Mounting | Floor Mounting | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Overall Cap., lbs. | Material | Color | Gauge | No. of Doors | Fasteners Included | No. of Holes | Hole Dia. | Fasteners Included | No. of Holes | Hole Dia. | Assembled or Unassembled | Features | Each | |

| 36" | 29" | 17" | 250 | Powder-Coated Steel | Blue | 16 | 1 | No | 4 | 5/8" | No | 2 | 3/4" | Assembled | Removable Chip Tray | 00000000 | 0000000 |

Bench-Top Manual Lathes

Compact enough for a workbench, these lathes are best for prototyping and one-off jobs in tool rooms or fabrication and maintenance shops. They do everything a full-size lathe can—turning, facing, threading, and knurling. Built from cast iron, they’re durable and stable. Plus, they have precision bearings in the headstock and spindle. They meet DIN 8606 for accuracy and performance.

Choose from six spindle speeds to tailor cuts to different materials and tasks. Because the speeds are set, you can’t fine-tune these lathes like you can with a variable-speed lathe.

Digital readout attachments display real-time tool positioning along two axes for increased machining accuracy.

Workbenches are made of steel and sized specifically for these lathes.

Spindle | Max. Workpiece | Overall | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Speeds | Speed, rpm | Dia. | Lg. | Turning Dia. | Bed Wd. | Spindle Morse Taper No. | Tailstock Morse Taper No. | Spindle Through-Hole Dia. | Ht. | Wd. | Dp. | Wt., lbs. | TIR (Total Indicated Runout) Accuracy | Features | Includes | Specifications Met | Each | |

120V AC—1 hp Brushless Motor | ||||||||||||||||||

| 6 | 150-2,400 | 9" | 21 5/8" | 9 13/16" | 5 5/16" | 4 | 2 | 1 1/64" | 19" | 50" | 23" | 280 | 0.001" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 000000000 |

Display | ||||||

|---|---|---|---|---|---|---|

| No. of Axes | Lg. | Wd. | Ht. | Mounting Fasteners Included | Each | |

| 2 | 3 7/8" | 2 1/2" | 5 1/4" | Yes | 00000000 | 0000000 |

Shelves | Machine Mounting | Floor Mounting | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Overall Cap., lbs. | Material | Color | Gauge | No. of Doors | No. of | Type | Cap., lbs. | Fasteners Included | No. of Holes | Hole Dia. | Fasteners Included | No. of Holes | Hole Dia. | Assembled or Unassembled | Each | |

| 29 1/4" | 35 1/2"-47" | 16" | 700 | Powder-Coated Steel | Blue | 16 | 2 | 2 | Fixed | 150 | No | 9 | 1/2" | No | 8 | 3/4" | Unassembled | 00000000 | 0000000 |

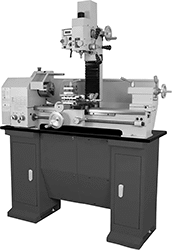

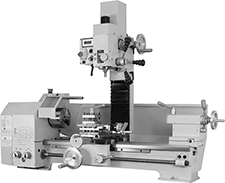

Bench-Top Combination Lathe, Mill, and Drill Machines

Turn, knurl, thread, mill, and drill workpieces with these compact machines. They can switch between rotating a blade and rotating a workpiece, so you can complete every step of fabrication. Small enough to fit on a workbench, they’re often used in tool rooms and maintenance shops—they’re best for prototyping and one-off jobs. A cast iron frame makes these machines durable and stable. For smooth motion, they have precision bearings in the headstock and spindle. All are built and tested to DIN 8606 standards for accuracy and performance.

Twist knobs on the front to choose from six spindle speeds, and you can tailor the cuts to different materials and tasks. These machines have set speeds, so you can’t fine-tune them with as much precision as variable-speed machines.

Digital readout attachments display the tool position in real time, which helps you machine more accurately. Two-axis attachments show the X and Y axes, which give you the position of the lathe. Three-axis attachments also show the Z axis.

Workbenches are made of steel and sized specifically for these machines.

Lathe Spindle | Max. Workpiece | Overall | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Speeds | Speed, rpm | Mill/Drill Spindle Speed, rpm | Dia. | Lg. | Turning Dia. | Bed Wd. | Lathe Spindle Morse Taper No. | Lathe Tailstock Morse Taper No. | Lathe Spindle Through-Hole Dia. | Spindle Morse Taper No. | Ht. | Wd. | Dp. | Wt., lbs. | TIR (Total Indicated Runout) Accuracy | Features | Includes | Specifications Met | Each | |

120V AC | ||||||||||||||||||||

1 hp Lathe Brushless Motor—0.625 hp Mill and Drill Brushless Motor | ||||||||||||||||||||

| 6 | 125-2,000 | 100-3,000 | 9" | 20" | 9 13/16" | 5 7/8" | 3 | 2 | 1" | 4 | 34" | 49" | 23" | 463 | 0.0005" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 000000000 |

1 hp Lathe Brushless Motor—1 hp Mill and Drill Brushless Motor | ||||||||||||||||||||

| 6 | 150-2,000 | 100-3,000 | 11" | 27" | 11" | 7 1/16" | 4 | 2 | 1" | 4 | 39" | 55" | 29" | 550 | 0.0005" | Chip Guard, Safety Guard | Gear Set, Manual Lathe Chuck, 4-Way Tool Post, Two Dead Centers | DIN 8606 | 00000000 | 00000000 |

Shelves | Machine Mounting | Floor Mounting | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Wd. | Dp. | Overall Cap., lbs. | Material | Color | Gauge | No. of Doors | No. of | Type | Cap., lbs. | Fasteners Included | No. of Holes | Hole Dia. | Fasteners Included | No. of Holes | Hole Dia. | Assembled or Unassembled | Each | |

| 29 1/4" | 35 1/2"-47" | 16" | 700 | Powder-Coated Steel | Blue | 16 | 2 | 2 | Fixed | 150 | No | 9 | 1/2" | No | 8 | 3/4" | Unassembled | 00000000 | 0000000 |

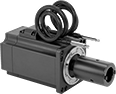

Probes for CNC Lathes

Take 3D measurements even in the harsh machining conditions of a CNC lathe. IP rated and built with a strengthened glass window, these probes seal out coolant and resist scratches from flying metal chips. Integrate them into your lathe’s control system to catch errors while your part is still on the machine—saving time and cutting down on material waste. Since they physically touch a part one point at a time, they accurately check distances, diameters, and angles. They can also be used to position a workpiece, locate holes and grooves, and check for scratches, dents, or other imperfections. However, they don’t work well on more complex features, like how round or flat a part is.

All probes require a probe styli. You’ll also need a receiver and an interface (sold separately) to communicate with your CNC lathe. Receivers send your probe’s data to interfaces, which need to be wired to your lathe’s control panel.

Infrared probes send data to a receiver up to 5 meters away, but because they use light, they need a clear view. These probes are typically found in small lathes with chuck sizes around 8” and medium lathes with chuck sizes around 15”. They can also be used on a 5-axis CNC with a table size under 1,500 mm.

Radio probes send data to a receiver up to 15 meters away. They block out interference from other radio devices, so you can use multiple radio probes in one machine shop. They’re used in small, medium, and large lathes with a chuck size up to 24". They can also be used on a 5-axis CNC with a table size under 3,500 mm.

Receiver mounting brackets (sold separately) make it easy to attach a receiver or receiver/interface to your lathe.

Conduit assemblies (sold separately) protect wiring from coolant and metal chips.

Use a shank (sold separately) to attach a probe to the spindle on your CNC lathe.

Probes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Stylus | Trigger Force, N | Replacement Batteries | |||||||||||||

| Dia., mm | Lg., mm | Thread Size | O'all Lg., mm | For Axis Measuring Direction | X- and Y-Axis | Z-Axis | Repeatability, mm | Max. Distance from Receiver, m | Environmental Rating | Manufacturer (Series) | Each | Pkg. Qty. | Pkg. | ||

Infrared | |||||||||||||||

| 40 | 58 | M4 | 50-150 | ±X, ±Y, +Z | 0.4, 0.8 | 5.3 | ±0.001 | 5 | IK02, IP08 | Renishaw (OLP40) | 0000000 | 000000000 | 1 | 0000000 | 00000 |

Radio | |||||||||||||||

| 40 | 58 | M4 | 50-150 | ±X, ±Y, +Z | 0.6, 0.97 | 6.23 | ±0.001 | 15 | IK02, IP08 | Renishaw (RLP40-QE) | 0000000 | 00000000 | 1 | 0000000 | 0000 |

| Component | For Max. No. of Probes | Wire Connection Type | Cord Lg., ft. | Manufacturer (Series) | Each | |

For Infrared Probes | ||||||

|---|---|---|---|---|---|---|

| Receiver | 4 | Wire Leads | 82 | Renishaw (OMM-2) | 0000000 | 000000000 |

| Interface | __ | Screw Terminals | __ | Renishaw (OSI) | 0000000 | 00000000 |

| Receiver/Interface | 2 | Wire Leads | 26 | Renishaw (OMI-2T) | 0000000 | 00000000 |

For Radio Probes | ||||||

| Receiver/Interface | 4 | Wire Leads | 49 | Renishaw (RMI-Q) | 0000000 | 00000000 |

| Material | Mounting Fasteners Included | Manufacturer | Manufacturer Model Number | Each | |

| Black Powder-Coated Steel | Yes | Renishaw | A-2033-0830 | 0000000 | 0000000 |

| For Probe Dia., mm | Shank Type | For Probe Manufacturer Series | Manufacturer | Manufacturer Model Number | Each | |

| 40 | Straight (1/2" Dia.) | OLP40, RLP40-QE | Renishaw | A-5625-1004 | 0000000 | 0000000 |

| 40 | Straight (1" Dia.) | OLP40, RLP40-QE | Renishaw | A-5625-1007 | 0000000 | 000000 |

| 40 | Straight (25mm Dia.) | OLP40, RLP40-QE | Renishaw | A-5625-1003 | 0000000 | 000000 |

| Conduit Trade Size | Cord Lg., ft. | Manufacturer | Manufacturer Model Number | Each | |

| 5/16 | 3 | Renishaw | A-4113-0306 | 0000000 | 000000 |