Filter by

Extension Force

Compression Force

Mounting Position

Performance

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

REACH

RoHS

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Seal Material

Color-Coded High-Force Gas Springs

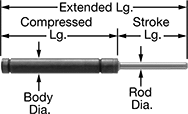

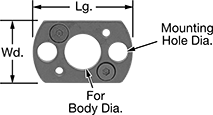

Extended Lg. | Compressed Lg. | Stroke Lg. | Max. Cycles per min., cpm | Max. Cycles | Lockable | Body Dia. | Rod Dia. | End Thread Size | Temp. Range, ° F | Choose an Extension Force | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Body and Rod | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.83" | 2.24" | 0.59" | 100 | Not Rated | No | 0.47" | 0.24" | M6 | 32 to 176 | 38 lbf (Green) , 75 lbf (Blue) , 113 lbf (Red) , 151 lbf (Yellow) | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.83" | 2.24" | 0.59" | 100 | Not Rated | No | 1" | 0.47" | M6 | 32 to 176 | 173 lbf (Green) , 346 lbf (Blue) , 519 lbf (Red) , 690 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.83" | 2.24" | 0.59" | 150 | Not Rated | No | 3/4" | 0.32" | M6 | 32 to 176 | 99 lbf (Green) , 164 lbf (Blue) , 225 lbf (Red) , 292 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.62" | 2.64" | 0.98" | 100 | Not Rated | No | 0.47" | 0.24" | M6 | 32 to 176 | 40 lbf (Green) , 80 lbf (Blue) , 119 lbf (Red) , 159 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.62" | 2.64" | 0.98" | 100 | Not Rated | No | 1" | 0.47" | M6 | 32 to 176 | 173 lbf (Green) , 346 lbf (Blue) , 519 lbf (Red) , 692 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.62" | 2.64" | 0.98" | 150 | Not Rated | No | 3/4" | 0.32" | M6 | 32 to 176 | 94 lbf (Green) , 157 lbf (Blue) , 220 lbf (Red) , 292 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.65" | 3.15" | 1.5" | 100 | Not Rated | No | 0.47" | 0.24" | M6 | 32 to 176 | 41 lbf (Green) , 82 lbf (Blue) , 123 lbf (Red) , 164 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.65" | 3.15" | 1.5" | 100 | Not Rated | No | 1" | 0.47" | M6 | 32 to 176 | 173 lbf (Green) , 346 lbf (Blue) , 522 lbf (Red) , 695 lbf (Yellow) | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.65" | 3.15" | 1.5" | 150 | Not Rated | No | 3/4" | 0.32" | M6 | 32 to 176 | 92 lbf (Green) , 155 lbf (Blue) , 218 lbf (Red) , 270 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.59" | 3.62" | 1.97" | 100 | Not Rated | No | 0.47" | 0.24" | M6 | 32 to 176 | 42 lbf (Green) , 83 lbf (Blue) , 125 lbf (Red) , 167 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.95" | 4.8" | 3.15" | 100 | Not Rated | No | 0.47" | 0.24" | M6 | 32 to 176 | 47 lbf (Green) , 93 lbf (Blue) , 139 lbf (Red) , 186 lbf (Yellow) | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.95" | 4.8" | 3.15" | 150 | Not Rated | No | 3/4" | 0.32" | M6 | 32 to 176 | 92 lbf (Green) , 152 lbf (Blue) , 214 lbf (Red) , 270 lbf (Yellow) | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.07" | 4.92" | 3.15" | 100 | Not Rated | No | 1" | 0.47" | M6 | 32 to 176 | 171 lbf (Green) , 342 lbf (Blue) , 513 lbf (Red) , 683 lbf (Yellow) | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

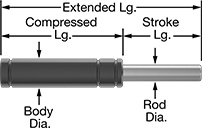

High-Force Gas Springs

Extended Lg. | Compressed Lg. | Stroke Lg. | Extension Force, lbf | Compression Force, lbf | Max. Cycles per min., cpm | Body Dia. | Rod Dia. | Port Thread Size | End Thread Size | Temp. Range, ° F | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel Body and Rod | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.68" | 1.93" | 0.75" | 380 | 630 | 40 | 3/4" | 0.43" | M6 | — | 32 to 176 | Black | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.68" | 1.93" | 0.75" | 720 | 1,150 | 40 | 1" | 0.59" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.68" | 1.93" | 0.75" | 810 | 1,260 | 40 | 1.26" | 0.63" | M6 | M6 | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.15" | 2.17" | 0.98" | 380 | 630 | 40 | 3/4" | 0.43" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.15" | 2.17" | 0.98" | 720 | 1,170 | 40 | 1" | 0.59" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.15" | 2.17" | 0.98" | 810 | 1,260 | 40 | 1.26" | 0.63" | M6 | M6 | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.18" | 2.68" | 1.5" | 380 | 630 | 40 | 3/4" | 0.43" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.18" | 2.68" | 1.5" | 720 | 1,190 | 40 | 1" | 0.59" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.18" | 2.68" | 1.5" | 810 | 1,240 | 40 | 1.26" | 0.63" | M6 | M6 | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.14" | 3.66" | 2.48" | 380 | 630 | 40 | 3/4" | 0.43" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.14" | 3.66" | 2.48" | 720 | 1,190 | 40 | 1" | 0.59" | M6 | — | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.14" | 3.66" | 2.48" | 810 | 1,260 | 40 | 1.26" | 0.63" | M6 | M6 | 32 to 176 | Black | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||