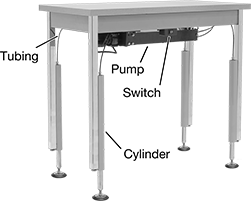

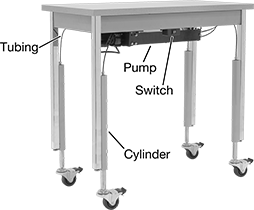

Hydraulic Lift Kits for Workbenches

Transform a fixed-height workbench into an adjustable-height workbench with one of these kits. They allow for fine adjustments to the workbench height.

To install, attach each cylinder to the workbench legs with fasteners (not included). Then, mount the pump under the workbench top and connect the cylinders to the pump with included tubing.

Stationary kits have leveling feet to compensate for uneven floors.

Kits with electric motor adjust height with the push of a button.

Cylinder | Cylinder Mtg. Holes | Pump Mtg. Holes | Switch Mtg. Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Min. Leg Ht. | Ht. Added | Wd. | Material | Cap., lbs. | No. of | Dia. | No. of | Dia. | No. of | Dia. | Mtg. Fasteners Included | Cord Lg. | Specifications Met | Each | |

Stationary | |||||||||||||||

Electric Motor with Three Prong Plug (120V AC) | |||||||||||||||

| 13 1/4" | 1 5/8"-7 5/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 000000000 |

| 15 1/4" | 1 5/8"-9 5/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| 19 1/4" | 1 5/8"-13 5/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| 23 1/4" | 1 5/8"-17 5/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

Mobile | |||||||||||||||

Electric Motor with Three Prong Plug (120V AC) | |||||||||||||||

| 13 1/4" | 4 7/8"-10 7/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| 15 1/4" | 4 7/8"-12 7/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| 19 1/4" | 4 7/8"-16 7/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| 23 1/4" | 4 7/8"-20 7/8" | 1 1/2" | Aluminum | 1,000 | 4 | 1/4" | 7 | 1/4" | 2 | 3/16" | No | 8 ft. | CSA Certified, UL Listed | 00000000 | 00000000 |

| Optional Maintenance Kit (Includes 10 Nuts and Ferrules, 16 oz. of Hydraulic Fluid, 36 ft. of Hydraulic Tubing, 8-oz. Filler Bottle with Needle) | 00000000 | Each | 000000 |

| Replacement Leveling Feet for Stationary Lift Kits | 000000000 | Each | 0000 |

| Replacement Gear Motor for Lift Kits with Electric Motor | 000000000 | Each | 000000 |

| Replacement Switch Assemblies for Lift Kits with Electric Motor | 00000000 | Each | 000000 |

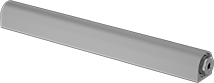

Cylinder | Cylinder Mtg. Holes | ||||||

|---|---|---|---|---|---|---|---|

| For Min. Leg Ht. | Ht. Added | Wd. | Material | No. of | Dia. | Each | |

For Stationary Lift Kits | |||||||

| 13 1/4" | 1 5/8"-7 5/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 0000000 |

| 15 1/4" | 1 5/8"-9 5/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

| 19 1/4" | 1 5/8"-13 5/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

| 23 1/4" | 1 5/8"-17 5/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

For Mobile Lift Kits | |||||||

| 13 1/4" | 4 7/8"-10 7/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

| 15 1/4" | 4 7/8"-12 7/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

| 19 1/4" | 4 7/8"-16 7/8" | 1 1/2" | Aluminum | 4 | 1/4" | 00000000 | 000000 |

| 23 1/4" | 4 7/8"-20 7/8" | 1 1/2" | Aluminum | 4 | 1/4" | 000000000 | 000000 |

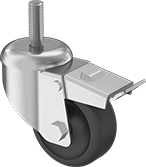

Wheel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Cap. per Caster, lbs. | Stem Thread Size | Stem Lg. | Wheel/Tread Material | Frame Material | Caster Type | Each | |

| 3" | 1 1/4" | 300 | 1/2"-13 | 1 1/2" | Polypropylene Plastic | Steel | Swivel with Brake | 000000000 | 000000 |

Electric Sit-Stand Workstations

Workstation | Dark Gray | Light Gray |

White | Red Woodgrain |

Switch between sitting and standing while working. Press a button on the height adjustment switch, and the electric motor raises or lowers these workstations to your desired height. Assign up to three different heights to the three program buttons—press a button to automatically adjust the desk to the programmed height. These workstations also have programmable upper and lower height limits, and a lock function to prevent accidental height changes.

Overall | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Top Color | Frame Color | Width | Depth | Height | Overall Capacity, lbs. | Elevation Speed, in./sec. | Assembled or Unassembled | Plug Type | Power Cord Length, ft. | Each | |

Plastic Laminate Top with Powder-Coated Steel Frame | |||||||||||

| Dark Gray | Silver | 48" | 30" | 27 1/2"-47" | 125 | 1 1/2 | Unassembled | Two Prong | 10 | 00000000 | 0000000 |

| Light Gray | Silver | 48" | 30" | 27 1/2"-47" | 125 | 1 1/2 | Unassembled | Two Prong | 10 | 00000000 | 000000 |

| White | Silver | 48" | 30" | 27 1/2"-47" | 125 | 1 1/2 | Unassembled | Two Prong | 10 | 00000000 | 000000 |

| Red Woodgrain | Black | 48" | 30" | 27 1/2"-47" | 125 | 1 1/2 | Unassembled | Two Prong | 10 | 00000000 | 000000 |

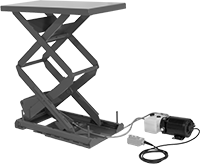

Electric Stationary Lift Tables

An electric motor and a hydraulic pump perform repetitive lifting and positioning with the push of a button. The NEMA rating only applies to the push-button control.

Lift table bellows (sold separately) protect the working parts of the table from dust, dirt, and debris.

Warning: Never use to lift people.

Lift Tables | Lift Table Bellows | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Ht. | Elevation Speed, in./sec. | Material | Duty Cycle | Motor Phase | Motor Full Load Current | Plug Type | Power Cord Lg., ft. | Control Cord Lg., ft. | Environmental Rating | Specifications Met | Each | Each | ||

Hand-Operated with 120V AC External Motor | |||||||||||||||||

| 550 | 32" | 19 1/2" | 6"-28" | 2 1/4 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 000000000 | 0000000 | 0000000 |

| 660 | 40" | 20" | 9 1/2"-54" | 3 1/4 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 00000000 |

| 1,100 | 25 1/2" | 18" | 8 1/2"-33 1/2" | 1 3/4 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 000000 |

| 1,100 | 40" | 20" | 6"-31 1/2" | 2 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 000000 |

| 1,650 | 40" | 20" | 6"-31 1/2" | 1 1/2 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 000000 |

Hand-Operated with 120V AC Internal Motor | |||||||||||||||||

| 2,000 | 48" | 28" | 8 1/2"-38 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 12 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 00000000 |

| 2,000 | 48" | 36" | 8 1/2"-38 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 15A | Three Prong | 8 | 10 | NEMA 12 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 00000000 |

| 3,000 | 48" | 28" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 3,000 | 48" | 36" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 56" | 32" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 72" | 48" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

Hand-Operated with 480V AC Internal Motor | |||||||||||||||||

| 3,000 | 48" | 28" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 3,000 | 48" | 36" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 56" | 32" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 72" | 48" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

Foot-Operated with 120V AC Internal Motor | |||||||||||||||||

| 3,000 | 48" | 28" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 3,000 | 48" | 36" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 56" | 32" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 72" | 48" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Single | 18A | Three Prong | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

Foot-Operated with 480V AC Internal Motor | |||||||||||||||||

| 3,000 | 48" | 28" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 3,000 | 48" | 36" | 8 1/2"-42 1/2" | 1 1/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 56" | 32" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

| 5,000 | 72" | 48" | 9"-48" | 3/4 | Steel | 9 cycles per hour | Three | 2.2A | __ | 8 | 10 | NEMA 1 | ANSI MH 29.1 | 00000000 | 00000000 | 0000000 | 00000000 |

Turntable-Top Electric Stationary Lift Tables

The turntable rotates to reduce reaching. Tables have an electric motor and a hydraulic pump that perform repetitive lifting and positioning with the push of a button. The NEMA rating only applies to the push-button control.

Lift table bellows (sold separately) protect the working parts of the table from dust, dirt, and debris.

Warning: Never use to lift people.

Lift Tables | Lift Table Bellows | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Ht. | Elevation Speed, in./sec. | Tabletop Ga. | Turntable Dia. | Material | Duty Cycle | Motor Full Load Current | Plug Type | Control Cord Lg., ft. | Environmental Rating | Specifications Met | Each | Each | ||

Round with 115V AC Motor | |||||||||||||||||

| 2,000 | __ | __ | 11 1/2"-41 1/2" | 2 1/2 | 10 | 43" | Steel | 25 cycles per hour | 20A | Three Prong | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 000000000 | 0000000 | 000000000 |

| 4,000 | __ | __ | 11 1/2"-41 1/2" | 1 | 10 | 43" | Steel | 25 cycles per hour | 20A | Three Prong | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 00000000 |

Square with 120V AC Motor | |||||||||||||||||

| 3,500 | 48" | 48" | 8"-44" | 3/4 | 7 | 43" | Steel | 20 cycles per hour | 17A | Three Prong | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 00000000 | 0000000 | 00000000 |

Long-Tabletop Electric Stationary Lift Tables

An extra-large tabletop provides plenty of room for oversized loads. Tables have an electric motor and a hydraulic pump that perform repetitive lifting and positioning with the push of a button. The NEMA rating only applies to the push-button control.

Lift table bellows (sold separately) protect the working parts of the table from dust, dirt, and debris.

Warning: Never use to lift people.

Lift Tables | Lift Table Bellows | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Ht. | Elevation Speed, in./sec. | Tabletop Ga. | Material | Duty Cycle | Motor Full Load Current | Plug Type | Power Cord Lg., ft. | Control Cord Lg., ft. | Environmental Rating | Specifications Met | Each | Each | ||

With 120V AC Motor | |||||||||||||||||

| 2,000 | 96" | 48" | 6 1/2"-42 1/2" | 3/4 | 7 | Steel | 12 cycles per hour | 8.4A | Three Prong | 10 | 10 | NEMA 1 | ANSI MH 29.1 | 0000000 | 0000000000 | 0000000 | 000000000 |

Floor-Load Electric Stationary Lift Tables

The tabletop can go as low as 3", making loading and unloading from the floor and pallets easier. Tables have an electric motor and a hydraulic pump that perform repetitive lifting and positioning with the push of a button. The NEMA rating only applies to the push-button control. A toe guard at the base of the table provides safety for the operator.

Warning: Never use to lift people.

Floor-Load Electric Stationary Lift Tables | Optional Loading Ramp | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, lbs. | Lg. | Wd. | Ht. | Elevation Speed, in./sec. | Tabletop Ga. | Duty Cycle | Motor Phase | Motor Full Load Current | Plug Type | Power Cord Lg., ft. | Control Cord Lg., ft. | Environmental Rating | Specifications Met | Includes | Each | Each | ||

With 120V AC Motor | ||||||||||||||||||

| 550 | 40" | 23 1/2" | 3"-29 1/2" | 2 1/2 | 10 | 9 cycles per hour | Single | 8.4A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 6-ft. Long Hydraulic Hose | 0000000 | 000000000 | 0000000 | 0000000 |

| 1,100 | 40" | 23 1/2" | 3"-30" | 1 1/4 | 10 | 9 cycles per hour | Single | 8.4A | Three Prong | 8 | 10 | NEMA 4 | ANSI MH 29.1 | 6-ft. Long Hydraulic Hose | 0000000 | 00000000 | 0000000 | 000000 |

Tilting Electric Stationary Lift Tables

Raise and tilt heavy loads for easy access at the angle you need. Often used to position containers, pallets, and other heavy items in loading docks and assembly areas, these tables help minimize strain during repetitive tasks. A motor-powered hydraulic pump adjusts loads with the push of a button. Tilt these tables up to a 40° angle. All have a retaining lip to keep items from sliding off when tilted.

| Capacity, lbs. | Lg. | Wd. | Ht. | Elevation Speed, in./sec. | Tabletop Ga. | Max. Tilt Angle | Lip Ht. | Material | Color | Duty Cycle | Motor Phase | Motor Full Load Current | Plug Type | Power Cord Lg., ft. | Control Cord Lg., ft. | Each | |

With 115V AC Motor | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2,000 | 48" | 48" | 8"-42 1/2" | 1 1/4 | 3 | 40° | 12" | Painted Steel | Blue | 10 cycles per hour | Single | 11A | Three Prong | 9 | 8 | 00000000 | 000000000 |

Electric Positioning Turntables

Often used in displays, these turntables have a motor for continuous rotation.

Style B have a three-prong outlet to power a mounted object.

Base Mounting Hole | Bearing | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Capacity, lbs. | OD | Overall Ht. | Turntable Speed, rpm | Voltage | Material | Mounting Fasteners Included | No. of | Dia. | Type | No. of | Material | Cord Lg., ft. | Each | |

Lubrication Not Required | |||||||||||||||

| A | 100 | 17" | 4 5/8" | 2 | 120V AC | Powder-Coated Steel | No | 4 | 3/16" | Ball Sleeve | 1 2 | Bronze Steel | 6 | 0000000 | 0000000 |

| A | 200 | 23" | 4 1/2" | 1 | 120V AC-240V AC | Powder-Coated Steel | Yes | 4 | 1/4" | Ball Sleeve | 1 2 | Bronze Steel | 6 | 0000000 | 00000000 |

| B | 100 | 6 3/8" | 5 1/2" | 2 | 120V AC | Painted Steel | No | 4 | 3/16" | Ball Sleeve | 1 2 | Bronze Steel | 6 | 0000000 | 000000 |

| B | 200 | 9 1/8" | 6 1/2" | 1 | 120V AC-240V AC | Powder-Coated Steel | Yes | 4 | 1/4" | Ball Sleeve | 1 2 | Bronze Steel | 6 | 0000000 | 00000000 |

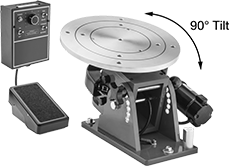

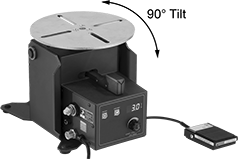

Electric Welding Positioners

Mount a workpiece on these motorized turntables for smooth and continuous 360° rotary motion useful for creating circular welds. Turntables tilt and lock in place at angles up to 90° in 15° increments. Once the workpiece is attached to the turntable or chuck, press the foot pedal to start the motor. As the part rotates, your hands are free to focus on the weld.

Load capacity is reduced as the table is tilted.

Positioners with a remote control box let you control the turntable cordlessly.

Use the optional three-jaw chuck to grip the outside of round items or the inside of pipe.

Base | Table Slots | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed Range, rpm | Max. Ground Current | Lg. | Wd. | O'all Ht. | Wt., lbs. | Tilt Increments | Rotation Range of Motion | No. of | Lg. | Wd. | Voltage | Frequency, Hz | Plug Type | Cord Lg., ft. | Features | Each | |

| 0.4-6 | 400A | 7" | 5" | 9" | 14 | 15° | 360° | 3 | 1 3/8" | 3/8" | 120V AC | 50, 60 | Three Prong | 8 | Grounding Stud | 00000000 | 000000000 |

| Optional Three-Jaw Chuck | 0000000 | Each | 0000000 |

Base | Table Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed Range, rpm | Max. Ground Current | Lg. | Wd. | O'all Ht. | Wt., lbs. | Tilt Increments | Rotation Range of Motion | No. of | Thread Size | Voltage | Frequency, Hz | Plug Type | Cord Lg., ft. | Features | Each | |

| 0-10 | 300A | 12" | 12" | 12" | 55 | 15° | 360° | 3, 9 | 5/16"-18, 1/2"-13 | 120V AC | 60 | Three Prong | 6 | Grounding Stud, Remote Control Box | 0000000 | 000000000 |

| Optional Three-Jaw Chuck | 0000000 | Each | 000000000 |

Base | Table Slots | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Speed Range Max., rpm | Max. Ground Current | Lg. | Wd. | O'all Ht. | Wt., lbs. | Tilt Increments | Rotation Range of Motion | No. of | Lg. | Wd. | Voltage | Frequency, Hz | Plug Type | Cord Lg., ft. | Features | Each | |

| 6 | 400A | 12 1/2" | 10 3/4" | 9 7/8" | 38 | 15° | 360° | 4 | 3 1/4" | 7/16" | 120V AC | 50, 60 | Three Prong | 8 | Grounding Stud | 00000000 | 000000000 |

| Optional Three-Jaw Chuck | 0000000 | Each | 0000000 |