Filter by

System of Measurement

Height

Maximum Flow Rate @ Pressure

Fitting Connection

Drive Style

Maximum Pressure

Diameter

Removes Particle Size Down To

Noise Reduction Rating

Maximum Temperature

Connects To

Inlet Thread Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Mufflers

|  | |||

Style A | Style C | Style F | Style G | Style H |

|  |  |  | |

Style J | Style K | Style L | Style M |

Mufflers with Pipe Connection

|  | |||

Style A | Style C | Style F | Style G | Style H |

|  |  |  | |

Style J | Style K | Style L | Style M |

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Max. Flow Rate @ Pressure | Max. Pressure, psi | Max. Temp., ° F | Ht. | Dia. | For Use With | Removes Particle Size Down To, μm | Noise Reduction Rating, dB | 1-24 | 25-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 21 scfm @ 100 psi | 175 | 175 | 1 3/4" | — | Air, Inert Gas | 40 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 67 scfm @ 100 psi | 145 | 175 | 7/8" | 1/2" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 71 scfm @ 100 psi | 145 | 175 | 1 3/16" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 85 scfm @ 100 psi | 175 | 175 | 1 3/4" | — | Air, Inert Gas | 40 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 115 scfm @ 100 psi | 145 | 175 | 1" | 5/8" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 139 scfm @ 100 psi | 175 | 175 | 2 1/8" | — | Air, Inert Gas | 40 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 162 scfm @ 100 psi | 145 | 175 | 1 3/8" | 3/4" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 164 scfm @ 100 psi | 145 | 175 | 1 5/8" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 197 scfm @ 100 psi | 175 | 175 | 2 11/16" | — | Air, Inert Gas | 40 | 10 to 20 | 0000000 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 244 scfm @ 100 psi | 145 | 175 | 1 3/4" | 15/16" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 244 scfm @ 100 psi | 145 | 175 | 1 13/16" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 scfm @ 100 psi | 145 | 175 | 2 1/4" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 389 scfm @ 100 psi | 145 | 175 | 2 7/16" | 1 1/2" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 396 scfm @ 100 psi | 145 | 175 | 2 5/8" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style C | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 61 scfm @ 100 psi | 145 | 300 | 13/16" | 3/8" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 100 scfm @ 100 psi | 145 | 300 | 1 1/16" | 1/2" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 141 scfm @ 100 psi | 145 | 300 | 1 7/16" | 5/8" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 210 scfm @ 100 psi | 145 | 300 | 1 3/4" | 3/4" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 301 scfm @ 100 psi | 145 | 300 | 2 1/2" | 1" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 5 scfm @ 100 psi | 175 | 175 | 1/2" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 25 scfm @ 100 psi | 175 | 175 | 5/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 25 scfm @ 100 psi | 175 | 175 | 5/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 38 scfm @ 100 psi | 175 | 175 | 3/4" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 38 scfm @ 100 psi | 175 | 175 | 11/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 56 scfm @ 100 psi | 175 | 175 | 13/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 56 scfm @ 100 psi | 175 | 175 | 11/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 126 scfm @ 100 psi | 175 | 175 | 7/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 126 scfm @ 100 psi | 175 | 175 | 11/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 149 scfm @ 100 psi | 175 | 175 | 1 1/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 270 scfm @ 100 psi | 175 | 175 | 1 1/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style G | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Nylon Fitting—Polyethylene Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 51 scfm @ 100 psi | 145 | 176 | 1 5/16" | 1/2" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 99 scfm @ 100 psi | 145 | 176 | 1 9/16" | 11/16" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 170 scfm @ 100 psi | 145 | 176 | 2 9/16" | 1" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 136 scfm @ 100 psi | 145 | 176 | 2 13/16" | 1" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 312 scfm @ 100 psi | 145 | 176 | 5 7/16" | 1 1/2" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 450 scfm @ 100 psi | 145 | 176 | 6 3/16" | 1 7/8" | Air, Inert Gas | 50 | 10 to 25 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style H | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 52 scfm @ 100 psi | 145 | 300 | 1 1/8" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 86 scfm @ 100 psi | 145 | 300 | 1 1/4" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 121 scfm @ 100 psi | 145 | 300 | 1 7/16" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 180 scfm @ 100 psi | 145 | 300 | 1 3/4" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 259 scfm @ 100 psi | 145 | 300 | 2 1/8" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 293 scfm @ 100 psi | 145 | 300 | 2 5/8" | — | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style J | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 25 scfm @ 100 psi | 175 | 175 | 1 1/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 35 scfm @ 100 psi | 175 | 175 | 1 5/16" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 53 scfm @ 100 psi | 175 | 175 | 1 1/2" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 00000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 125 scfm @ 100 psi | 175 | 175 | 1 5/8" | — | Air, Inert Gas | 100 | 10 to 20 | 0000000 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style K | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Brass Fitting—Brass Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 25 scfm @ 100 psi | 145 | 175 | 3/16" | 3/8" | Air, Inert Gas | 120 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 71 scfm @ 100 psi | 145 | 175 | 5/8" | 3/8" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 38 scfm @ 100 psi | 145 | 175 | 1/4" | 1/2" | Air, Inert Gas | 120 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 116 scfm @ 100 psi | 145 | 175 | 3/4" | 1/2" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 56 scfm @ 100 psi | 145 | 175 | 1/4" | 5/8" | Air, Inert Gas | 120 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 164 scfm @ 100 psi | 145 | 175 | 13/16" | 5/8" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 126 scfm @ 100 psi | 145 | 175 | 3/8" | 3/4" | Air, Inert Gas | 120 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 244 scfm @ 100 psi | 145 | 175 | 1 1/16" | 3/4" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 350 scfm @ 100 psi | 145 | 175 | 1 7/16" | 1" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 270 scfm @ 100 psi | 145 | 175 | 7/16" | 1 1/4" | Air, Inert Gas | 120 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 396 scfm @ 100 psi | 145 | 175 | 1 13/16" | 1 1/4" | Air, Inert Gas | 50 | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style L | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Nylon Fitting—Nylon Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 32 scfm @ 100 psi | 85 | 155 | 1 3/8" | 5/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 39 scfm @ 100 psi | 85 | 155 | 1 3/4" | 3/4" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 42 scfm @ 100 psi | 85 | 155 | 2 1/4" | 15/16" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 49 scfm @ 100 psi | 85 | 155 | 2 1/4" | 15/16" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 88 scfm @ 100 psi | 85 | 155 | 4 9/16" | 1 7/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 134 scfm @ 100 psi | 85 | 155 | 4 9/16" | 1 7/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style M | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Threaded Male Acetal Fitting—Acetal Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 32 scfm @ 100 psi | 85 | 120 | 1 5/16" | 5/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 39 scfm @ 100 psi | 85 | 120 | 1 11/16" | 13/16" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 42 scfm @ 100 psi | 85 | 120 | 2 5/16" | 1" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2 | 49 scfm @ 100 psi | 85 | 120 | 2 5/16" | 1" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 0000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4 | 88 scfm @ 100 psi | 85 | 120 | 4 5/16" | 1 7/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 134 scfm @ 100 psi | 85 | 120 | 4 9/16" | 1 7/8" | Air, Inert Gas | Not Rated | 10 to 20 | 0000000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

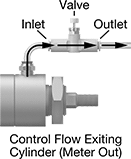

Air-Exhaust Flow Control Valves

Overall, mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Flow Ports | Inlet Size | Max. Flow Rate @ Pressure | Flow Coefficient (Cv) | Max. Pressure, psi | Body Material | Hex Size, mm | Dia | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Male Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Adjustment Dial | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/8 BSPP | 35 scfm @ 100 psi | 1.016 | 145 | Aluminum | — | 16 | 46 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/4 BSPP | 52.5 scfm @ 100 psi | 1.524 | 145 | Aluminum | — | 19.5 | 63.3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/8 BSPP | 59.5 scfm @ 100 psi | 1.728 | 145 | Aluminum | — | 25 | 95.3 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2 BSPP | 141.26 scfm @ 100 psi | 2.982 | 145 | Aluminum | — | 28 | 130 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/4 BSPP | 268.39 scfm @ 100 psi | 5.965 | 145 | Aluminum | — | 38 | 157 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flow-Adjustment Slotted Screw | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/8 BSPP | 19.21 scfm @ 100 psi | 0.52 | 145 | Aluminum | 14 | 15 | 27 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/4 BSPP | 37 scfm @ 100 psi | 1 | 145 | Aluminum | 17 | 18.2 | 32.1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 3/8 BSPP | 74 scfm @ 100 psi | 2 | 145 | Aluminum | 22 | 25 | 41.1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 1/2 BSPP | 133.2 scfm @ 100 psi | 3.6 | 145 | Aluminum | 24 | 27 | 44.6 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

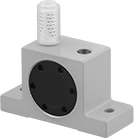

Flow-Control Mufflers

Mufflers with External Hex Drive

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Pipe Size | Max. Flow Rate @ Pressure | Max. Pressure, psi | Max. Temp., ° F | Ht. | For Use With | Removes Particle Size Down To, μm | Noise Reduction Rating, dB | Features | 1-19 | 20-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BSPP Male Nylon Fitting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8 | 51 scfm @ 100 psi | 145 | 210 | 13/16" | Air, Inert Gas | 75 | 10 to 20 | Adjustable Airflow | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4 | 5.25 scfm @ 100 psi | 145 | 175 | 1 3/16" | Air, Inert Gas | 50 | 10 to 20 | Adjustable Airflow | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8 | 170 scfm @ 100 psi | 145 | 210 | 1 1/2" | Air, Inert Gas | 75 | 10 to 20 | Adjustable Airflow | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Energy-Saving Air-Powered Vibrators for Dry Materials

Base Mounting Hole with Top Inlet

Inlet Air Connection | Outlet Air Conection | Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Content Wt., lb. | Force @ Pressure | Vibration Freq. @ Pressure | Pipe Size | Type | Thread Type | Gender | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Volume @ Pressure | No. of | Dia. | Ctr.-to-Ctr. | Wd. | Ht. | Dp. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 200 | 42 lbf @ 80 psi | 15,600 vpm @ 80 psi | 1/8 | Threaded | BSPP | Female | 1/8 | BSPP | Female | 3.5 ft³/min @ 80 psi | 69 dBA @ 80 psi | 2 | 7/32" | 2.25" | 2 13/16" | 1 5/8" | 1 1/8" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 300 | 55 lbf @ 80 psi | 12,500 vpm @ 80 psi | 1/8 | Threaded | BSPP | Female | 1/8 | BSPP | Female | 3.5 ft³/min @ 80 psi | 68 dBA @ 80 psi | 2 | 7/32" | 2.25" | 2 13/16" | 1 5/8" | 1 1/8" | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 4,600 | 460 lbf @ 80 psi | 36,000 vpm @ 80 psi | 1/8 | Threaded | BSPP | Female | 1/8 | BSPP | Female | 4 ft³/min @ 80 psi | 69 dBA @ 80 psi | 2 | 9/32" | 2.688" | 3 7/16" | 2" | 1 5/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5,800 | 580 lbf @ 80 psi | 44,000 vpm @ 80 psi | 1/8 | Threaded | BSPP | Female | 1/8 | BSPP | Female | 4 ft³/min @ 80 psi | 70 dBA @ 80 psi | 2 | 9/32" | 2.688" | 3 7/16" | 2" | 1 5/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 6,400 | 640 lbf @ 80 psi | 22,000 vpm @ 80 psi | 1/4 | Threaded | BSPP | Female | 1/4 | BSPP | Female | 10 ft³/min @ 80 psi | 72 dBA @ 80 psi | 2 | 11/32" | 3.563" | 4 7/16" | 2 9/16" | 1 11/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 7,500 | 750 lbf @ 80 psi | 31,000 vpm @ 80 psi | 1/4 | Threaded | BSPP | Female | 1/4 | BSPP | Female | 10 ft³/min @ 80 psi | 74 dBA @ 80 psi | 2 | 11/32" | 3.563" | 4 7/16" | 2 9/16" | 1 11/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 11,000 | 1,100 lbf @ 80 psi | 22,000 vpm @ 80 psi | 1/4 | Threaded | BSPP | Female | 1/4 | BSPP | Female | 15 ft³/min @ 80 psi | 75 dBA @ 80 psi | 2 | 11/32" | 4.125" | 5 1/16" | 3 3/16" | 2 3/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 12,300 | 1,230 lbf @ 80 psi | 16,000 vpm @ 80 psi | 3/8 | Threaded | BSPP | Female | 3/8 | BSPP | Female | 26 ft³/min @ 80 psi | 80 dBA @ 80 psi | 2 | 7/16" | 5.125" | 6 5/16" | 3 15/16" | 2 15/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 13,800 | 1,380 lbf @ 80 psi | 12,000 vpm @ 80 psi | 3/8 | Threaded | BSPP | Female | 3/8 | BSPP | Female | 24 ft³/min @ 80 psi | 78 dBA @ 80 psi | 2 | 7/16" | 5.125" | 6 5/16" | 3 15/16" | 2 15/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Vibrators for Wet Materials

End Mount with Top Inlet Pipe Connection

Inlet Air Connection | Outlet Air Conection | Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Wall Thk. | Force @ Pressure | Vibration Freq. @ Pressure | Pipe Size | Type | Thread Type | Pipe Size | Thread Type | Air Consumption @ Pressure | Volume @ Pressure | No. of | Dia., mm | Wd. | Ht. | Piston Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1/32" | 17 lbf @ 80 psi | 6,500 vpm @ 80 psi | 1/8 | Threaded | BSPP | 1/8 | BSPP | 0.5 ft³/min @ 80 psi | 59 dBA @ 80 psi | 1 | 8 | 3 3/16" | 1 1/4" | Standard | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1/16" | 38 lbf @ 80 psi | 5,600 vpm @ 80 psi | 1/8 | Threaded | BSPP | 1/8 | BSPP | 1.6 ft³/min @ 80 psi | 64 dBA @ 80 psi | 1 | 10 | 3 11/16" | 1 9/16" | Standard | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 1/8" | 105 lbf @ 80 psi | 4,100 vpm @ 80 psi | 1/8 | Threaded | BSPP | 1/4 | BSPP | 2.7 ft³/min @ 80 psi | 72 dBA @ 80 psi | 1 | 12 | 4 9/16" | 1 7/8" | Standard | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3/16" | 220 lbf @ 80 psi | 4,400 vpm @ 80 psi | 1/4 | Threaded | BSPP | 1/4 | BSPP | 4.5 ft³/min @ 80 psi | 74 dBA @ 80 psi | 1 | 12 | 4 9/16" | 2 1/4" | Standard | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Vibrators for Dry Materials

Base Mounting Hole with Top Inlet

Inlet Air Connection | Outlet Air Conection | Mounting Holes | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | For Content Wt., lb. | Force @ Pressure | Vibration Freq. @ Pressure | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Air Consumption @ Pressure | Volume @ Pressure | No. of | Dia. | Ctr.-to-Ctr. | Wd. | Ht. | Dp. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 720 | 72 lbf @ 80 psi | 34,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 6 ft³/min @ 80 psi | 75 dBA @ 80 psi | 4 | 17/64" | 2 11/16" | 3 3/8" | 2" | 13/16" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1,410 | 141 lbf @ 80 psi | 29,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 6.5 ft³/min @ 80 psi | 77 dBA @ 80 psi | 4 | 17/64" | 2 11/16" | 3 3/8" | 2" | 13/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 1,800 | 180 lbf @ 80 psi | 22,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 7 ft³/min @ 80 psi | 78 dBA @ 80 psi | 4 | 11/32" | 3 9/16" | 4 7/16" | 2 9/16" | 15/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 2,250 | 225 lbf @ 80 psi | 18,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 9 ft³/min @ 80 psi | 81 dBA @ 80 psi | 4 | 11/32" | 3 9/16" | 4 7/16" | 2 9/16" | 1 1/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3,400 | 340 lbf @ 80 psi | 15,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 11 ft³/min @ 80 psi | 85 dBA @ 80 psi | 4 | 11/32" | 4 1/8" | 5 1/16" | 3 3/16" | 1 5/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 4,200 | 420 lbf @ 80 psi | 13,000 vpm @ 80 psi | 1/4 | BSPP | Female | 1/4 | BSPP | Female | 14 ft³/min @ 80 psi | 82 dBA @ 80 psi | 4 | 11/32" | 4 1/8" | 5 1/16" | 3 3/16" | 1 1/2" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||