How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Hose

More

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have a gasket to prevent leaks.

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met: See table

316 Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | Max. Steam Pressure | For Use With | Specifications Met | Each | |

NPTF Male × UN/UNF (SAE Straight) Male | |||||||||

| 1/2 | 08 | 7/8"-14 | 10 | 5,400 psi @ 72° F | 5,400 psi @ 200° F | Hydraulic Fluid, Oil, Steam, Water | SAE J514 | 51205K523 | 000000 |

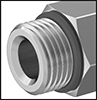

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings.

NPTF (Dryseal) threads are compatible with NPT threads. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have either a gasket or a gasket and washer to prevent leaks.

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met:

NPTF and UN/UNF (SAE Straight): ASTM A108

BSPP: ISO 1179, ISO 8434-6

BSPT: DIN EN 10226-1, ISO 7-1

| Thread Size | Dash Size | Max. Pressure | Material | For Use With | Each | |

UN/UNF (SAE Straight) Male | ||||||

|---|---|---|---|---|---|---|

| 7/8"-14 | 10 | 5,000 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Water | 50925K567 | 000000 |

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPTF Male × UN/UNF (SAE Straight) Male | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 08 | 7/8"-14 | 10 | 6,000 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Water | ASTM A108 | 50925K333 | 00000 |

Metal Push-On Barbed Hose Fittings for Air and Water

Fittings have sharper barbs than standard barbed hose fittings to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip.

Brass fittings are softer than other metal fittings, so they’re easier to thread together. They have good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance, so they’re the best choice for high-humidity environments.

Fittings that swivel until tightened rotate 360° for easy installation.

Fittings with a flared end meet JIC or SAE standards for dimensions. Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings. Fittings with a female 37° and 45° flared end have a dual-angle seat that accepts both 37° and 45° flared fittings.

The optional installation tool (sold separately) allows you to connect large quantities of barbed fittings to push-on hose. Use the built-in cutter to squarely cut the hose without fraying. Next, lubricate either the push-on hose, fitting or both. Then, clamp the hose into the tool’s vise and apply light pressure on the handle to drive into the fitting.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

- Maximum Pressure: 300 psi @ 72° F

- Temperature Range: -20° to 150° F

- Specifications Met: SAE J512, SAE J514

Mounting Hole | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | Lg. | Ht. | Dp. | Dia. | No. of | Mounting Fasteners Included | Each | |

| 1/4" to 3/4" | 13 1/2" | 7" | 2 3/8" | 5/8" | 4 | No | 53685K11 | 0000000 |

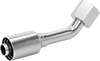

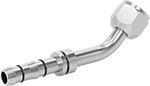

Crimp-On Hose Fittings for Hydraulic Fluid

Crimp these fittings onto hydraulic hose for a permanent, leak-tight connection. Since they crimp on, they handle higher pressure than screw-on fittings. To install, use Parker crimping tools and dies (not included).

Fittings with a female end swivel 360° until tightened without you needing to move or twist the entire hose, making them easy to install.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Note: Fittings are only for use with hydraulic hose.

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 43 Series | |||||||

| 5/8" | 15/16" | 5/8" | 7/8"-14 | 10 | 4,000 psi @ 72° F | 7175N41 | 000000 |

- Maximum Pressure: See table

- Temperature Range: -40° to 210° F

- For Hose Manufacturer Series:

Parker 43 Series Fittings: 302 SAE J517 100R2AT, 422 SAE J517 100R1AT, 487 ISO17582-AC, 777 ISO17582-CC

Parker 56 Series Fittings: 510D J517 SAE 100R7, 518D J517 SAE 100R7

For Hose | |||||||

|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 43 Series | |||||||

| 5/8" | 15/16" | 5/8" | 7/8"-14 | 10 | 4,000 psi @ 72° F | 7175N32 | 000000 |

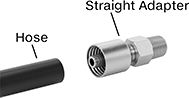

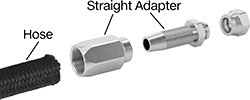

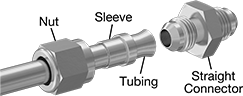

Screw-On Hose Fittings for D.O.T. Hose

Create or repair D.O.T. hose assemblies in the field with just a wrench and a vise, no crimper required. To install, separate the two pieces of these fittings. Screw the hose-end portion onto your hose, then thread the nipple portion into the hose-end portion. When assembled, these fittings compress against the hose to form a strong seal. Also known as reusable fittings, they can be unscrewed from your hose and used on a new one. All meet labeling and performance requirements for motor vehicle brake hose fittings.

Fittings with a flared tube connection swivel 360° until tightened for easy installation. Those with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

- Maximum Pressure: See table

- Temperature Range: -40° to 300° F

- Specifications Met: D.O.T. FMVSS 106, SAE J517 100R5

- For Hose Manufacturer Series: Parker 201 SAE J517 100R5

For Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Thread Type | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 20 Series | ||||||||

| 1/2" | 15/16" | 5/8" | 7/8"-14 | UN/UNF (JIC) | 10 | 1,750 psi @ 72° F | 7161N15 | 000000 |

- Maximum Pressure: See table

- Temperature Range: -40° to 300° F

- Specifications Met: D.O.T. FMVSS 106, SAE J517 100R5

- For Hose Manufacturer Series: Parker 201 SAE J517 100R5

For Hose | ||||||||

|---|---|---|---|---|---|---|---|---|

| ID | OD | For Tube OD | Thread Size | Thread Type | Dash Size | Max. Pressure | Each | |

Zinc-Plated Steel—Parker 20 Series | ||||||||

| 1/2" | 15/16" | 5/8" | 7/8"-14 | UN/UNF (SAE 45°) | 10 | 1,750 psi @ 72° F | 7161N19 | 000000 |

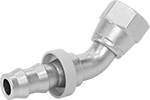

Push-On Barbed Hose Fittings for Hydraulic Fluid

These fittings have sharp barbs to grip rubber push-on hose with no clamps or ferrules required. The more you pull on the fittings, the tighter the hose will grip. Use them in low-pressure hydraulic applications up to 350 psi. Also known as hose nipples, they adapt a barbed end to a threaded end, so you can connect to pumps, cylinders, and other equipment in your hydraulic system. Fittings are zinc-plated steel, which has excellent strength and durability. Fittings have fair corrosion resistance.

Fittings that swivel until tightened rotate 360° for easy installation.

Fittings with a 37° flared end are also known as JIC (Joint Industrial Council) fittings.

Note: To ensure proper connection, the barbed end has to be pushed in all the way, with the hose end concealed by the ring.

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

- Specifications Met: See Table

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

- Maximum Pressure: See table

- Maximum Vacuum: See Table

- Temperature Range: -40° to 255° F

- For Hose Manufacturer Series: Parker 801

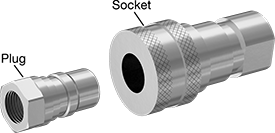

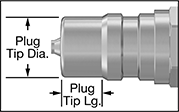

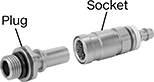

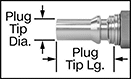

International Standard ISO B Quick-Disconnect

Hose Couplings for Hydraulic Fluid

A complete coupling consists of a plug and a socket (both sold separately) that connect and disconnect quickly. Use them if you need frequent access to a hydraulic hose line. All of the International Standard ISO B quick-disconnect plugs are compatible with any of the International Standard ISO B quick-disconnect sockets of the same coupling size, regardless of the pipe size. Couplings meet ISO 7241-1 Series B dimensional and performance standards and are compatible with Parker 60 couplings. Also known as double shut-off couplings, the plugs and sockets both have a shut-off valve that stops the flow when the coupling is separated.

Plugs are also known as nipples.

Zinc-plated steel is stronger and more durable than other metals. It has fair corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

Warning: Never attempt to connect or disconnect couplings when operating at maximum pressure. Stop the flow before you disconnect the line.

- Maximum Pressure: See table

- Maximum Vacuum: 27 in. of Hg @ 72° F

- Temperature Range: -40° to 250° F

- Compatible With: ISO 7241-1 Series B, Parker 60

- Specifications Met: ISO 7241-1 Series B

Minimal-Spill Quick-Disconnect Hose Couplings for Coolant

Reduce the risk of spills near electronics when connecting and disconnecting liquid cooling lines. Also known as double shut-off couplings, these couplings have a shut-off valve on both sides that stops the flow of coolant if they’re separated. Often used to connect servers to a cooling manifold in data centers, they comply with the performance specifications of OCP (Open Computing Project). To avoid mixing up your lines, choose blue couplings for cold supply and red couplings for hot return. A complete coupling consists of a plug and socket or two adapters (all sold separately).

Install plugs on manifolds and servers. They’re also known as nipples. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- Maximum Pressure: 150 psi @ 72° F

- Temperature Range: 65° to 145° F

- Material: 303 Stainless Steel

- Compatible With: Danfoss Hansen UQD, Parker Hannifin UQD, CEJN UQD, CPC UQD, Staubli UQD

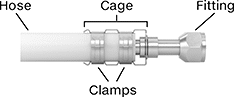

Refrigerant Hose Fittings

- Maximum Pressure: 500 psi @ 72° F

- Maximum Vacuum: 28 in. of Hg @ 72° F

- Temperature Range: -40° to 280° F

- Compatible With: Danfoss EZ Clip

- All Fittings Swivel Until Tightened

- Specifications Met: SAE J2064, SAE J3062

- Compatible Hose: Refrigerant Hose

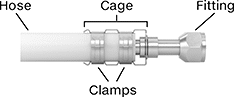

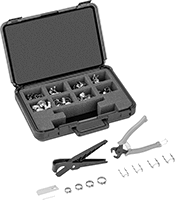

No need for expensive crimping tools—these fittings make air conditioning and refrigeration assemblies with clamps. Instead of a crimper, they use two clamps that you tighten against a cage on your fitting with pliers. Both fitting ends swivel until tightened, so you don't have to rotate the entire hose during installation. The cage and clamps stretch out after use, so they shouldn't be used again.

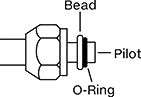

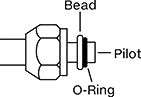

Fittings with an O-ring pilot create a leak-tight seal, so they’re often used in commercial and vehicle air conditioning systems. When you screw the fitting onto your tube, the bead and the pilot squeeze the O-ring, which fills in any gaps. The pilot also helps guide your hose onto the fitting, making it easy to properly align and secure the connection.

Dash Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID | For Hose | Fitting | Thread Size | Bead OD | Pilot Lg. | Includes | Each | |

Zinc-Plated Steel | ||||||||

| 5/8" | 12 | 10 | 7/8"-14 | 0.77" | 0.19" | 2 Clamps, Cage, O-Ring | 6124N26 | 000000 |

Dash Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Hose ID | For Hose | Fitting | Thread Size | Bead OD | Pilot Lg. | Includes | Each | |

Zinc-Plated Steel | ||||||||

| 1/2" | 10 | 10 | 7/8"-14 | 0.77" | 0.19" | 2 Clamps, Cage, O-Ring | 6124N31 | 000000 |

Jaw | |||||||

|---|---|---|---|---|---|---|---|

| Overall Lg. | Grip Style | Opening Style | Texture | Material | Tip Type | Each | |

Pinch Clamp Pliers—Straight Jaw | |||||||

| 6 7/8" | Cushion | Spring Assisted | Smooth | Steel | Fixed | 6124N12 | 0000000 |

Band | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Hose ID Range | For OD | Dash Size | Wd. | Thick. | Reusable | Number of Pieces | Includes | Each | |

304 Stainless Steel Clamps with 301 Stainless Steel Cages | |||||||||

Single Pinch | |||||||||

| 5/16" to 5/8" | 0.6" to 0.99" | 06, 08, 10, 12 | 5/16" | 0.024" | No | 122 | Cages with 5/16" band width for 5/16" hose ID (10 each) Clamps with 5/16" band width, .32" clamp ID (20 each) Cages with 5/16" band width for 13/32" hose ID (10 each) Clamps with 5/16" band width, .42" clamp ID (20 each) Cages with 5/16" band width for 1/2" hose ID (10 each) Clamps with 5/16" band width, .52" clamp ID (20 each) Cages with 5/16" band width for 5/8" hose ID (10 each) Clamps with 5/16" band width, .62" clamp ID (20 each) Pinch Clamp Pliers Hose Cutter | 6124N11 | 0000000 |

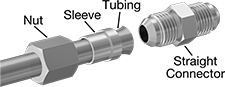

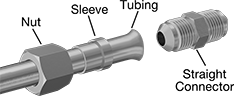

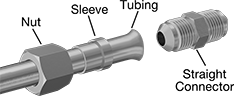

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See table

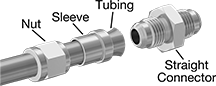

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

BSPP threads and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | Thread Size | For Use With | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/2 | __ | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | __ | 6,000 psi @ 72° F | -420° to 1200° | 50715K269 | 000000 |

UN/UNF (SAE Straight) Threads | |||||||||

| 5/8" | __ | 3/4"-16 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Buna-N Rubber | 3,500 psi @ 72° F | -20° to 240° | 50715K914 | 00000 |

| 5/8" | __ | 7/8"-14 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Fluoroelastomer Rubber | 6,000 psi @ 72° F | -15° to 400° | 50715K834 | 00000 |

| 5/8" | __ | 1 1/16"-12 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Buna-N Rubber | 6,000 psi @ 72° F | -30° to 250° | 50715K961 | 00000 |

| 3/4" | __ | 7/8"-14 | Air, Hydraulic Fluid, Isopropyl Alcohol, Water | 316 Stainless Steel | Fluoroelastomer Rubber | 6,000 psi @ 72° F | -15° to 400° | 50715K131 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 5/8" | 316 Stainless Steel | 50715K636 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 5/8" | 316 Stainless Steel | 50715K628 | 000000 |

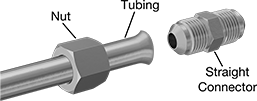

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except adapters for 1/8" and 1" tube OD are not for use with fuel oil

- Specifications Met: See table

For Tube | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Specifications Met | 1-9 | 10-49 | 50-Up | |

NPTF Threads | |||||||||

| 5/8" | 0.035" | 1/4 | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 50635K389 | 000000 | 00000 | 00000 |

| 5/8" | 0.035" | 3/8 | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 50635K391 | 0000 | 0000 | 0000 |

| 5/8" | 0.035" | 1/2 | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 50635K392 | 0000 | 0000 | 0000 |

| 5/8" | 0.035" | 3/4 | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 50635K393 | 00000 | 0000 | 0000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

For Tube | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Lg. | 1-19 | 20-99 | 100-Up | ||

Short Nuts | |||||||||

| A | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 1 1/16" | 50635K653 | 00000 | 00000 | 00000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 5/16" | 50635K566 | 0000 | 0000 | 0000 |

| B | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 31/32" | 50635K664 | 0000 | 0000 | 0000 |

Long Nuts | |||||||||

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 7/8" | 50635K556 | 00000 | 00000 | 00000 |

37° Flared Fittings for Copper Tubing

- For Use With: Air, Fuel Oil, Mineral Oil, Water

- Temperature Range: -40° to 400° F

- Tubing: Use with seamless copper

- Specifications Met: ISO 8434, MIL-F-18866, SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They can handle higher pressures than 45° flared fittings. Fittings are brass for good corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

37° Flared Fittings for Steel Tubing

Male Threads

with Gasket

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

To prevent leaks, UN/UNF (SAE Straight) male threads have a gasket. Metric and BSPP male threads have either a gasket or a gasket and washer.

Male Threads

with Gasket

- Temperature Range: See table

| For Tube OD | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

NPTF Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 5/8" | 1/2 | __ | __ | Zinc-Plated Steel | __ | 3,000 psi @ 72° F | -60° to 400° | 50695K269 | 00000 |

Metric Threads | |||||||||

| 5/8" | __ | M18 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | 2,300 psi @ 72° F | -30° to 200° | 4545K507 | 00000 |

| 5/8" | __ | M20 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | 2,300 psi @ 72° F | -30° to 200° | 4545K508 | 00000 |

| 5/8" | __ | M22 | 1.5 | Zinc-Plated Steel | Buna-N Rubber | 2,300 psi @ 72° F | -30° to 200° | 4545K509 | 00000 |

BSPP Threads | |||||||||

| 5/8" | 3/8 | __ | __ | Zinc-Plated Steel | Buna-N Rubber | 4,000 psi @ 72° F | -30° to 200° | 4545K532 | 00000 |

| 5/8" | 1/2 | __ | __ | Zinc-Plated Steel | Buna-N Rubber | 4,000 psi @ 72° F | -30° to 200° | 4545K533 | 00000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

Inch × metric sleeve adapters convert the fitting from inch to metric.

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 5/8" | Zinc-Plated Steel | 3,000 psi @ 72° F | 50695K636 | 00000 |

37° Flared Fittings for Aluminum Tubing

- For Use With: Air, Coolant, Gasoline, Hydraulic Fluid, Water

- Temperature Range: -60° to 400° F

- Tubing: Use with seamless aluminum

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings are aluminum, which is lightweight with good corrosion resistance. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 5/8" | 1/2 | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 2227K18 | 00000 |

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 5/8" | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 2227K66 | 00000 |

| For Tube OD | Sleeve Material | Max. Pressure | Each | |

| 5/8" | Anodized 2024 Aluminum | 3,000 psi @ 72° F | 2227K76 | 00000 |