About Hearing Protection

Earmuffs and earplugs are rated by the Noise Reduction Rating (NRR) guidelines, which are enforced by OSHA.

More

Sound Level Testers

Take readings of ambient sound levels. These portable testers give you spot readings, so you can monitor workplace machinery and vehicles, comply with safety regulations, and adhere to noise ordinances.

Testers have a selectable frequency weighting—an electronic filter that adjusts the way the tester measures sound. The A weighting is similar to the response of the human ear and is used by OSHA. The C weighting is suitable for measuring the sound level of machinery.

Testers with NIST certification include a calibration certificate traceable to NIST.

Testers with a backlit display can be read in dim areas.

Testers with an SD card store timestamped readings in Excel format for easy data logging and PC transfer. The SD card stores up to 20 million readings.

Use the calibrator (sold separately) to calibrate the tester before each use and verify that it is working properly.

| Measuring Range, dBA | Sound Frequency Weighting | Accuracy, dB | Data Connection Type | Ht. | Wd. | Dp. | Batteries Included | Features | Includes | Specs. Met | Each | ||

Testers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 40-130 | A, C | ±2.0 | __ | 9" | 2 1/4" | 1 3/4" | Yes | __ | __ | __ | 00000000 | 000000 |

| 2 | 35-130 | A, C | ±1.0 | __ | 6" | 1 1/4" | 1 1/4" | Yes | Backlit Display, Wrist Strap | Windscreen | ANSI S1.4 Type 2 | 00000000 | 000000 |

| 2 | 35-130 | A, C | ±1.5 | 3.5 mm Audio | 10" | 3" | 1 1/2" | Yes | Backlit Display | Storage Case | ANSI S1.4 Type 2 | 00000000 | 000000 |

| 3 | 30-130 | A, C | ±1.4 | 3.5 mm Audio, Standard SD Card | 9" | 2 1/4" | 1 1/4" | Yes | Backlit Display | 1 GB SD Card, Storage Case, Windscreen | ANSI S1.4 Type 2 | 00000000 | 000000 |

Testers with NIST Certificate | |||||||||||||

| 1 | 40-130 | A, C | ±2.0 | __ | 9" | 2 1/4" | 1 3/4" | Yes | __ | __ | __ | 00000000 | 000000 |

| 2 | 35-130 | A, C | ±1.5 | 3.5 mm Audio | 10" | 3" | 1 1/2" | Yes | Backlit Display | Storage Case | ANSI S1.4 Type 2 | 0000000 | 000000 |

Kits include a tester, calibrator, and calibration screwdriver to help calibrate your tester before every use.

| Measuring Range, dBA | Sound Frequency Weighting | Accuracy, dB | Ht. | Wd. | Dp. | Batteries Included | Features | Includes | Specs. Met | Each | |

Kits | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 35-130 | A,C | ±1.5 | 8" | 2 1/4" | 1 1/4" | Yes | Backlit Display | Calibrator, Screwdriver, Storage Case, Windscreen | ANSI S1.4 Type 2 | 00000000 | 0000000 |

Kits with NIST Certificate | |||||||||||

| 35-130 | A,C | ±1.5 | 8" | 2 1/4" | 1 1/4" | Yes | Backlit Display | Calibrator, Screwdriver, Storage Case, Windscreen | ANSI S1.4 Type 2 | 00000000 | 000000 |

Make sure your sound level monitor or tester provides reliable readings. These calibrators have a small speaker that generates sound at precise levels, so your monitor can be accurately calibrated before each use.

Sound | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Microphone Dia. | Frequency, Hz | Frequency Accuracy | Volume, dB | Volume Accuracy, dB | Dia. | Lg. | Mount Type | Batteries Included | Includes | Each | |

| 1/2", 1" | 1,000 | ±5% | 94 | ±0.5 | 2 1/8" | 5 5/8" | Portable | Yes | Screwdriver, Storage Case | 00000000 | 0000000 |

Sound Level Monitors

Continuously measure ambient sound levels. The display alerts you when levels either exceed or fall below your programmed thresholds. When operating the monitor with the included 120V AC adapter, four warning lights will also flash when a threshold is reached. Monitors have a microphone that rotates 180°. They can be surface mounted or propped up using the attached folding stand. These monitors cannot be sold to Canada due to import regulations.

You can select the frequency weighting—an electronic filter that adjusts the way the monitor measures sound. The A weighting is similar to the response of the human ear and is used by OSHA. The C weighting is suitable for measuring the sound level of machinery.

Use a calibrator (sold separately) to calibrate the monitor on a regular basis and verify that it is working properly.

| Measuring Range, dB | Sound Frequency Weighting | Fasteners Included | Mounting Hole Dia. | Power Source | Electrical Connection | Batteries Included | Number of Batteries Required | Battery Size | Specifications Met | Cannot Be Sold To | Each | |

Monitors | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30-130 | A, C | No | 1/2" | Battery, Electric | Plug In | No | 8 | AA | ANSI S1.4 | Canada | 0000000 | 0000000 |

Monitors With NIST Certificate | ||||||||||||

| 30-130 | A, C | No | 1/2" | Battery, Electric | Plug In | No | 8 | AA | ANSI S1.4 | Canada | 0000000 | 000000 |

Make sure your sound level monitor or tester provides reliable readings. These calibrators have a small speaker that generates sound at precise levels, so your monitor can be accurately calibrated before each use.

Sound | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Microphone Dia. | Frequency, Hz | Frequency Accuracy | Volume, dB | Volume Accuracy, dB | Dia. | Lg. | Mount Type | Batteries Included | Includes | Each | |

| 1/2", 1" | 1,000 | ±5% | 94 | ±0.5 | 2 1/8" | 5 5/8" | Portable | Yes | Screwdriver, Storage Case | 00000000 | 0000000 |

Personal Sound Exposure Monitors

Clip these monitors on to measure your noise exposure. Also known as personal noise dosimeters, they continuously measure ambient sound levels, intensity, and duration. You’ll often see them used in factories, airports, and construction sites to help comply with OSHA regulations for noise exposure. These monitors give noise dose as a percentage of the maximum safe daily limit and alert you when levels are outside your set threshold. You can choose from preprogrammed sound level tests or program your own. Set the monitor to record automatically or program it to record samples at timed intervals.

An electronic filter adjusts the way these testers measure sound, so you can choose the frequency weighting you need. The A weighting mimics the human ear’s response to sound. It is used by OSHA to measure the risk of potential hearing damage. The C weighting measures low-frequency sounds, so it’s often used to measure the sound level of machinery. The Z weighting gives you a flat frequency response and represents the actual noise without any adjustments.

Transmit readings to your PC with the included cord. The included software lets you review stored sound measurements and analyze measurements in real time.

Use a calibrator (sold separately) before and after each use to keep monitors accurate and maintain compliance with ANSI standards.

| Measuring Range, dBA | Sound Frequency Weighting | Mount Type | Accuracy, dB | Data Connection Type | Ht. | Wd. | Dp. | Batteries Included | Includes | Sound Level Tests | Each | |

| 30-140 | A, C, Z | Portable | ±1.4 | Mini USB-B | 4" | 2 1/4" | 1 1/4" | Yes | 1/2" Clip-On Microphone, 32" Lg Microphone Cord, 6 ft. Long USB Cord, Belt Clip, Storage Case, Windows Compatible Software, Windscreen | ACGIH Threshold Limit Values for Physical Agents, DOD Instruction 4715.13, ISO 9612, MSHA Compliant 30 CFR 62.170, OSHA Compliant 29 CFR 1910.95 | 0000000 | 0000000 |

Make sure your sound level monitor or tester provides reliable readings. These calibrators have a small speaker that generates sound at precise levels, so your monitor can be accurately calibrated before each use.

Sound | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Microphone Dia. | Frequency, Hz | Frequency Accuracy | Volume, dB | Volume Accuracy, dB | Dia. | Lg. | Mount Type | Batteries Included | Includes | Each | |

| 1/2", 1" | 1,000 | ±5% | 94 | ±0.5 | 2 1/8" | 5 5/8" | Portable | Yes | Screwdriver, Storage Case | 00000000 | 0000000 |

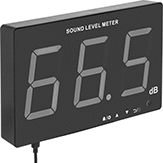

Large-Display Sound Level Monitors

Mount these monitors to your wall to view the sound level of your plant from 100 feet away. This helps you continuously keep an eye on the amount of noise in your work environment to make sure it’s safe. When the sound level exceeds your programmed threshold, the numbers on these monitors will turn from green to red. The A weighting is similar to the response of the human ear and is used by OSHA.

Attach them with the mounting holes on the back. The included cord lets you transmit data to your computer.

Mounting Hole | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range, dB | Sound Frequency Weighting | Accuracy, dBA | Data Connection Type | Character Ht. | Mount Type | Fasteners Included | Dia. | No. of | Power Source | Voltage | Plug Type | Cord Lg., ft. | Specifications Met | Each | |

| 30-130 | A | ±1.5 | Micro USB-B | 3" | Surface | No | 1/4" | 4 | Electric | 5V DC | USB-A | 2 1/2 | CE Marked | 0000000 | 0000000 |

Make sure your sound level monitor or tester provides reliable readings. These calibrators have a small speaker that generates sound at precise levels, so your monitor can be accurately calibrated before each use.

Sound | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| For Microphone Dia. | Frequency, Hz | Frequency Accuracy | Volume, dB | Volume Accuracy, dB | Dia. | Lg. | Mount Type | Batteries Included | Includes | Each | |

| 1/2", 1" | 1,000 | ±5% | 94 | ±0.5 | 2 1/8" | 5 5/8" | Portable | Yes | Screwdriver, Storage Case | 00000000 | 0000000 |

Vibration Meters with Stethoscopes

In addition to measuring vibration, you can listen to and record machine performance. The magnetic base allows you to mount the probe on a machine for constant readings.

| Measures | Vibration Range, cpm | Acceleration Range, g | Frequency Range, Hz | Speed Range, in./sec. | Accuracy | Temp. Range, °F | Probe Lg. | Batteries Included | Container Type | Each | |

| Vibration, Acceleration, Frequency, Speed | 600-600,000 | 0.01-19.99 | 10-10,000 | 0.01-19.99 | ±2% | -10° to 120° | 4 1/2" | Yes | Case | 000000 | 000000000 |

Digital Pocket Vibration Meters

Keep these meters on hand to quickly check the health of your machine and bearings. They digitally measure acceleration, frequency, and speed to help you identify potential problems, such as bearings that are off balance or misaligned. These meters have two different bases for taking readings. The magnetic base is useful for hands-free readings on magnetic surfaces. For nonmagnetic surfaces, use the pin tip and gently hold the meter against the vibrating surface. Rated IP65, these meters will continue to measure in dusty and damp workspaces.

| Measures | Acceleration Range, g | Frequency Range, Hz | Speed Range, in./sec. | Accuracy | Probe Lg. | Batteries Included | Container Type | Environmental Rating | Includes | Each | |

| Acceleration, Frequency, Speed | 0.5-20.39 | 10-1,000 | 0.02-7.87 | +/- 5% | 1 3/16" | Yes | Pouch | IP65 | Magnetic Base, Pin Tip | 0000000 | 0000000 |

Vibration Meters

In addition to vibration, these meters measure acceleration, frequency, speed, displacement, and temperature. Use them to gauge the health of your bearings and machines. Onscreen analytics allow you to instantly check the condition of your equipment. These meters store up to 3,500 readings in memory, and you can transfer them to your computer with a USB cord (not included) to track trends.

Import regulations restrict sales to the listed areas.

Add a probe to take measurements in hard-to-access areas. It has a magnetic base you can mount to a machine to get constant readings.

| Measures | Vibration Range, cpm | Acceleration Range, g | Frequency Range, Hz | Speed Range, in./sec. | Displacement Range, mil | Temp. Range, °F | Accuracy | Max. Reading Display Time | Probe Lg. | Batteries Included | Container Type | Cannot Be Sold To | Each | |

| Vibration, Acceleration, Frequency, Displacement, Speed, Temperature | 600-60,000 | 0.01-50 | 10-1,000 | 0.06-307 | 1-4,889 | 0° to 390° | ±5% | 3 min. | 1/64" | Yes | Case | Canada | 000000 | 000000000 |

Hearing Protection Fit Testing Systems

In a matter of minutes, confirm your earplugs deliver the right level of hearing protection. These kits help you meet OSHA standards for protection from excessive noise. Conduct the test onsite—everything you need, including a tablet with software already installed, is included. To use this kit, you will undergo a hearing test with and without your earplugs to determine the lowest volume you can hear. The system then calculates the difference between the scores and produces a personal attenuation rating (PAR).

Once the test is complete, you’ll receive a full report to help you choose the best earplugs. The results automatically upload to cloud storage and can be accessed on multiple devices.

Ear Cup | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range, dB | Accuracy, dB | Frequency Range, Hz | Connection Type | Range, ft. | Material | Color | Ear Cushion Material | Headband Material | Batteries Included | Sound Level Tests | Includes | Software Included | Each | |

Over Head Fit | ||||||||||||||

Dual Output | ||||||||||||||

| 0-100 | ±3 | 200-800 | Bluetooth | 160 | Plastic | Black | Foam | Plastic | Yes | OSHA Compliant 29 CFR 1910.95 | Headphones, Tablet, Cloud Storage, Carrying Case | Yes | 00000000 | 000000000 |

Acoustic Imaging Gas Leak Detectors

Locate leaks up to 10 times faster than traditional leak-detecting methods. These detectors use 124 microphones to determine the precise location and size of leaks in compressed air and specific gas systems. The screen displays a high-resolution acoustic image that’s overlaid on a digital live shot of your facility to help you visualize the leak. It also displays analytics related to the leak, such as the rate and the potential cost savings of patching your system. You can capture the on-screen view through photos and video to review later. With a built-in flashlight, they remain accurate even in low-light spaces. Light enough to carry with one hand, you can bring these detectors on the go. A 650 ft. range means you can use them from one end of your facility to another, or to detect in hard-to-reach systems.

Connect the detector to your computer using Wi-Fi or the included USB cable to quickly transfer collected data.

| Max. Working Distance, ft. | Measuring Range, kHz | Screen Size | Resolution Range | Data Connection Type | Wt., lbs. | Housing Material | Temp. Range, °F | Environmental Rating | Batteries Included | Container Type | Includes | Features | Each | |

| 650 | 2 to 130 | 5" | 1°-0.125° | Wi-Fi, USB-A | 3.2 | Plastic | 0° to 120° | IP54 | Yes | Plastic Carrying Case | Battery Charger, Charging Cord, Lanyard, USB Drive | Memory Storage, LED Flashlight | 0000000 | 0000000000 |

Ultrasonic Gas Leak Detectors

This detector converts ultrasonic waves to an audible sound so you can find leaks. Unlike typical leak detectors, this unit doesn’t rely only on the presence of a gas to work, making it suitable for a wider range of applications. In addition to gas leaks, it identifies ultrasonic sound caused by failing solenoids, valves, and bearings.

For systems under 10 psi, use the optional ultrasonic sound generator.

Import regulations restrict sales to the listed areas.

Grease-Dispensing Monitors

Extend the life of bearings by using these monitors to take the guesswork out of lubrication. Their sensor captures the ultrasonic vibration of grease as it fills your bearing and converts it into sound you can hear. As your bearing draws in the grease, the sound becomes quieter. Even in loud machine shops, you'll be able to track this sound with the noise-cancelling headphones and noise level readings shown on the monitor's screen. When the noise level stops decreasing, the bearing can't absorb any more grease and you should stop pumping grease to avoid over-lubricating your bearing.

The handset guides you through the steps for setting the noise level before applying grease. Use either the curved or flat magnetic mount to attach the sensor to the bearing. The monitor mounts to your grease gun, so you’ll have your hands free for pumping grease.

Headphones | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Measuring Range, kHz | Display Type | Maximum Noise Output, dB | Noise Reduction Rating, dB | Run Time, hrs. | Batteries Included | Housing Material | Container Type | Temperature Range, °F | Environmental Rating | Includes | Each | |

| 35 to 42 | OLED | 83 | 25 | 7 | Yes | ABS Plastic | Plastic Case | 14° to 122° | IP42 | Monitor Headphones Sensor Cord Grease Sensor Grease Sensor Adapter Curved Magnetic Sensor Mount Flat Magnetic Sensor Mount Hook and Loop Grease Gun Mount Magnetic Grease Gun Mount | 0000000 | 000000000 |

| Component | Includes | Each | |

| Monitor | __ | 00000000 | 000000000 |

| Headphones | __ | 00000000 | 000000 |

| Sensor Kit | Sensor Cord Grease Sensor Grease Sensor Adapter Curved Magnetic Sensor Mount Flat Magnetic Sensor Mount | 00000000 | 00000000 |

| Grease Gun Mounts | Hook and Loop Grease Gun Mount Magnetic Grease Gun Mount | 00000000 | 000000 |

| Plastic Case | __ | 00000000 | 000000 |