Filter by

Thread Size

Nut Type

Travel Distance per Turn

Thread Direction

Diameter

Dynamic Thrust Load Capacity

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Hardness

Performance

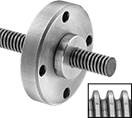

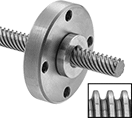

Metric Ultra-Precision Lead Screws and Nuts

|  |  |  |  |

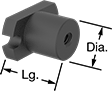

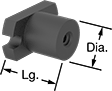

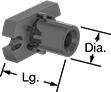

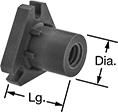

Style A | Style B | Style C | Style D |

Externally Threaded Nuts—Right-Hand Thread

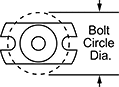

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Hex Wd. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M2 × 0.5 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 10 | -40 to 185 | 7549K58 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M4 × 0.3 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 0.3 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 25 | -40 to 185 | 7549K59 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M8 × 1.5 mm | 1" | — | — | 0.548" | 11/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 1.5 | 5/8"-18 | 1/4" | Not Rated | 8,000 | 75 | -40 to 185 | 7549K61 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 0.375 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 90500A220 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M3 × 0.5 mm | 13/32" | 0.311" | 0.276" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | M7 × 0.75 mm | 5/32" | Durometer 83D | Not Rated | 5 | — | 90500A230 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M4 × 1 mm | 1/2" | 0.402" | 0.354" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 1 | M9 × 1 mm | 13/64" | Durometer 83D | Not Rated | 10 | — | 90500A240 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

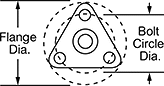

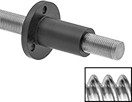

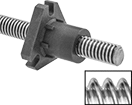

Flange Nuts—Right-Hand Thread

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Dia. | Dia. | Wd. | Ht. | Thk. | Thread Type | Speed Ratio | Bolt Circle Dia. | No. of Thread Starts | Travel Distance per Turn, mm | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.5 mm | 1/2" | 0.297" | — | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 1:1 | 39/64" | 1 | 0.5 | Not Rated | 8,000 | 10 | 2 | -40 to 185 | 7549K62 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M4 × 0.3 mm | 1/2" | 0.297" | — | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 1:1 | 39/64" | 1 | 0.3 | Not Rated | 8,000 | 25 | 2 | -40 to 185 | 7549K63 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | M8 × 1.5 mm | 3/4" | 0.548" | 1 1/8" | — | — | 3/16" | Metric Rounded Trapezoidal | 1:1 | 7/8" | 1 | 1.5 | Not Rated | 8,000 | 75 | 3 | -40 to 185 | 7549K64 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 9/32" | 0.209" | — | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 1:1 | 11/32" | 1 | 0.375 | Durometer 83D | Not Rated | 2 | 2 | — | 90500A250 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M3 × 0.5 mm | 21/64" | 0.295" | — | 39/64" | 5/16" | 3/32" | Metric Rounded Trapezoidal | 1:1 | 15/32" | 1 | 0.5 | Durometer 83D | Not Rated | 5 | 2 | — | 90500A260 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M4 × 1 mm | 13/32" | 0.354" | — | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 1:1 | 19/32" | 1 | 1 | Durometer 83D | Not Rated | 10 | 2 | — | 90500A270 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK with Wear-Compensating Internal O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.228" | — | 15/32" | 15/64" | 5/64" | Metric Rounded Trapezoidal | 1:1 | 11/32" | 1 | 0.375 | Durometer 83D | Not Rated | 1 | 2 | — | 90500A280 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M3 × 0.5 mm | 25/64" | 0.315" | — | 39/64" | 5/16" | 3/32" | Metric Rounded Trapezoidal | 1:1 | 15/32" | 1 | 0.5 | Durometer 83D | Not Rated | 2 | 2 | — | 90500A290 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M4 × 1 mm | 31/64" | 0.406" | — | 3/4" | 13/32" | 1/8" | Metric Rounded Trapezoidal | 1:1 | 19/32" | 1 | 1 | Durometer 83D | Not Rated | 5 | 2 | — | 90500A310 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precision Acme Lead Screws and Nuts

Round Nuts—Right-Hand Thread

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.125" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K134 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K138 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.083" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K149 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.063" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K39 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 1" | 1.465" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 1349K141 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 1 1/4" | 1.859" | Acme | 1:1 | 1 | 0.2" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 1349K23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1 1/4" | 1.859" | Acme | 1:1 | 1 | 0.125" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 1349K136 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 1349K143 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K121 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.167" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K129 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K145 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Nuts—Left-Hand Thread

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.125" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K135 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K139 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 3/4" | 1.344" | Acme | 1:1 | 1 | 0.083" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K151 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 1" | 1.465" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 1349K142 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1 1/4" | 1.859" | Acme | 1:1 | 1 | 0.125" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 1349K137 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 1349K144 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K122 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.167" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K131 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/2" | 2.234" | Acme | 1:1 | 1 | 0.1" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 1349K146 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 95075A210 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.05" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 95075A340 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.125" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A224 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.1" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A227 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.083" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A104 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A229 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 95075A106 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 1:1 | 1 | 0.125" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 95075A109 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 95075A249 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 95075A112 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.167" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 95075A113 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 95075A114 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 95075A118 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 95075A119 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.167" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 95075A120 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 95075A121 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Not Rated | Not Rated | 3,900 | 15 to 175 | 95075A218 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Not Rated | Not Rated | 6,000 | 15 to 175 | 95075A219 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-4 | 3 15/32" | 2.75" | Acme | 1:1 | 1 | 0.25" | 2 35/64"-18 | 7/8" | Acme Class 2C | Not Rated | Not Rated | 10,000 | 15 to 175 | 95075A222 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

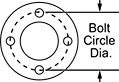

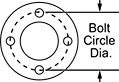

Flanges

|

|

Flange Thread Size | Flange Dia. | Flange Thk. | Bolt Circle Dia. | Flange Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 95082A644 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 156 | 95082A645 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 156 | 95082A646 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 135 | 1329K101 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 39/64" | 17/32" | 2 3/32" | Brinell 135 | 1329K102 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 135 | 1329K104 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 135 | 1329K105 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1215 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 95082A641 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 95082A642 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 1329K11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 1329K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 1329K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 140 | 1329K15 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 140 | 1329K16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fast-Travel Precision Acme Lead Screws and Nuts

Round Nuts—Right-Hand Thread

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-12 | 3/4" | 1.344" | Acme | 4:1 | 4 | 0.333" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 1349K105 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 3/4" | 1.344" | Acme | 2:1 | 2 | 0.25" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K107 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 3/4" | 1.344" | Acme | 4:1 | 4 | 0.5" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K101 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 3/4" | 1.344" | Acme | 2:1 | 2 | 0.2" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 1349K118 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-8 | 1" | 1.469" | Acme | 2:1 | 2 | 0.25" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 1349K15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 1" | 1.469" | Acme | 2:1 | 2 | 0.2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 1349K22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 1" | 1.469" | Acme | 5:1 | 5 | 0.5" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 1349K103 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-12 | 5/8" | 0.688" | Acme | 4:1 | 4 | 0.333" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 95075A207 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-5 | 5/8" | 0.688" | Acme | 5:1 | 5 | 1" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 250 | 15 to 175 | 95075A101 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.25" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A226 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 4:1 | 4 | 0.5" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A225 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.2" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 95075A228 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-8 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.25" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 95075A105 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.2" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 95075A247 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 5:1 | 5 | 0.5" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 95075A245 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 4:1 | 4 | 0.5" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 95075A230 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.5" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 95075A260 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanges

|

|

Flange Thread Size | Flange Dia. | Flange Thk. | Bolt Circle Dia. | Flange Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 95082A644 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1215 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 95082A641 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 95082A642 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 95082A643 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 1329K11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 1329K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 1329K13 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 1329K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fast-Travel Ultra-Precision Lead Screws and Nuts

Flange Nuts—Right-Hand Thread

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Dia. | Wd. | Ht. | Thk. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Mounting Hole Ctr.-to-Ctr. | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 2:1 | 2 | 0.096" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K23 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32"-21.3 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 2:1 | 2 | 0.094" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K25 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/16"-42.7 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 16:1 | 16 | 0.375" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K57 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 7/32"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 4:1 | 4 | 0.192" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal with Wear-Compensating Internal O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 2:1 | 2 | 0.096" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K33 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/32"-21.3 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 2:1 | 2 | 0.094" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K35 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/16"-42.7 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 16:1 | 16 | 0.375" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K67 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 7/32"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 4:1 | 4 | 0.192" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K36 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Precision Lead Screws and Nuts

Flange Nuts—Right-Hand Thread

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Dia. | Wd. | Ht. | Thk. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Mounting Hole Ctr.-to-Ctr. | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | No. of Mounting Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.048" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-41.7 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.024" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 7/32"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.048" | 39/64" | Not Rated | Not Rated | 25 | 2 | 6642K24 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal with Wear-Compensating Internal O-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.048" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K32 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9/64"-41.7 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.024" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 7/32"-20.8 | 1/2" | 0.406" | 3/4" | 13/32" | 1/8" | Rounded Acme | 1:1 | 1 | 0.048" | 39/64" | Not Rated | Not Rated | 5 | 2 | 6642K34 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||