Filter by

Material

TIG Welding Type

Nozzle Connection

TIG Industry Number

Nozzle Material

Fitting Connection

Welding Process

For Use With

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Pipe Size

TIG Torch Nozzles

|  |

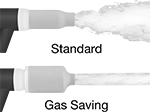

Standard | Gas Saving |

|  |  |  |

Ceramic Alumina for Narrow Gas Coverage | Ceramic Alumina for Wide Gas Coverage | Silicon Nitride Ceramic for Narrow Gas Coverage |

For Torch Series No. | TIG Torch Nozzle Size | For Electrode Dia. | TIG Industry No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ceramic Alumina for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 4 | — | 13N08 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 13N09 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 6 | — | 13N10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 7 | — | 13N11 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 8 | — | 13N12 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 10 | — | 13N13 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 10N50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 10N49 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 10N48 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 10N47 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 10N46 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 10 | — | 10N45 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 12 | — | 10N44 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 4 | — | 53N58 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 5 | — | 53N59 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 6 | — | 53N60 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 7 | — | 53N61 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | 8 | — | 53N61S | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 54N18 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 54N17 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 54N16 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 54N15 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 54N14 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic Alumina for Wide Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.063" | 53N6CN2-16 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.094" | 53N6CN2-32 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | — | 0.125" | 53N6CN2-18 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Silicon Nitride Ceramic for Narrow Gas Coverage | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 4 | — | 13N08SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 5 | — | 13N09SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 6 | — | 13N10SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 7 | — | 13N11SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 8 | — | 13N12SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 10 | — | 13N13SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 10N50SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 10N49SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 10N48SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 10N47SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 10N46SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 10 | — | 10N45SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 12 | — | 10N44SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 4 | — | 53N58SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 5 | — | 53N59SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 6 | — | 53N60SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 7 | — | 53N61SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 8 | — | 53N61SSC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 4 | — | 54N18SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 5 | — | 54N17SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 6 | — | 54N16SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 7 | — | 54N15SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 8 | — | 54N14SC | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Abrasive Blasting Nozzles

Tip | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

ID | OD | ID | OD | Overall Lg. | Bore Shape | Airflow Pattern | For Mfr. (Model No.) | Thread Size | Pipe Size | Thread Type | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Taper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Focused Airflow Pattern | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 5/16" | 13/64" | 7/16" | 1 5/16" | Funnel | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/16" | 7/32" | 7/16" | 1 5/16" | Funnel | Focused | — | — | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/8" | 1/8" | 1 1/8" | 3 3/4" | Straight | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 5/8" | 5/32" | 1 1/8" | 3 3/4" | Straight | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1/2" | 3/16" | 5/8" | 3" | Straight | Focused | Port-A-Blast (30D, 30S, 30SM) | — | 1/4 | NPT | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5/8" | 3/16" | 1 1/8" | 3 3/4" | Straight | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5/8" | 1/4" | 1 1/8" | 3 3/4" | Straight | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/8" | 5/8" | 1 1/8" | 3 3/4" | Funnel | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Focused Airflow Pattern | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1/2" | 3/16" | 1/2" | 3" | Straight | Focused | Zendex (007R SpeedBlaster) | — | 1/4 | NPT | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5/8" | 1/4" | 5/8" | 2 3/8" | Taper | Focused | Dee Blast (100) | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/64" | 1/2" | 13/64" | 1/2" | 1 1/2" | Straight | Focused | ALC (11665, 40153, 40162) | — | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/2" | 1/4" | 1/2" | 1 1/2" | Straight | Focused | ALC (11665, 40153, 40162) | — | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/4" | 1/4" | 3/4" | 2 1/2" | Straight | Focused | Econoline (201788) | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 7/8" | 45/64" | 7/8" | 1 3/8" | Funnel | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/8" | 9/32" | 5/8" | 4" | Straight | Focused | Blowers (QB2) | 11/16"-24 | — | UNF | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1/2" | 5/16" | 1/2" | 1 1/2" | Straight | Focused | ALC (11665, 40153, 40162) | — | — | — | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5/8" | 1/4" | 5/8" | 2 3/8" | Taper | Focused | Dee Blast (100) | — | — | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | 45/64" | 7/8" | 1 3/8" | Funnel | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 7/8" | 45/64" | 7/8" | 1 3/8" | Funnel | Focused | — | — | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

TIG Torch Gas Diffusers

For Ceramic Alumina Nozzles and Silicon Nitride Ceramic Nozzles

For Narrow Gas Coverage | For Narrow or Wide Gas Coverage | |||||

|---|---|---|---|---|---|---|

For Torch Series No. | Choose an Electrode Diameter (TIG Industry Number) | Each | Each | |||

| 9, 20, 25 | 0.020" (45V41) | 000000000 | 000000 | ——— | 0 | |

| 9, 20, 25 | 0.040" (45V42) | 000000000 | 00000 | ——— | 0 | |

| 9, 20, 25 | 0.063" (45V43) | ——— | 0 | 000000000 | 000000 | |

| 9, 20, 25 | 0.094" (45V44) | ——— | 0 | 000000000 | 00000 | |

| 9, 20, 25 | 0.125" (45V45) | ——— | 0 | 000000000 | 00000 | |

| 17, 18, 26 | 0.040" (45V24), 0.063" (45V25), 0.094" (45V26), 0.125" (45V27), 0.156" (45V28) | 00000000 | 00000 | ——— | 0 | |

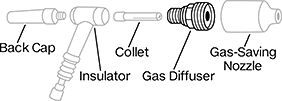

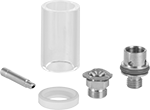

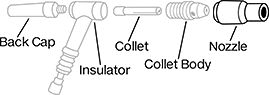

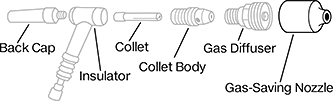

TIG Torch Accessory Kits

For Narrow Gas Coverage | For Wide Gas Coverage | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Torch Series No. | For Electrode Dia. | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic Alumina Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 0.040", 0.063" | Long Back Cap 0.040" Collet 0.063" Collet 0.040" Collet Body 0.063" Collet Body Size 4 Aluminum Oxide Ceramic Nozzle Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.040" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 0.040", 0.063", 0.094" | Short Back Cap 0.040" Collet 0.063" Collet 0.094" Collet 0.040" Collet Body 0.063" Collet Body 0.094" Collet Body Size 4 Aluminum Oxide Ceramic Nozzle Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.040" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18, 26 | 0.063", 0.094", 0.125" | Short Back Cap 0.063" Collet 0.094" Collet 0.125" Collet 0.063" Collet Body 0.094" Collet Body 0.125" Collet Body Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle Size 8 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.125" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0.063", 0.094", 0.125" | Long Back Cap 0.063" Collet 0.094" Collet 0.125" Collet 0.063" Collet Body 0.094" Collet Body 0.125" Collet Body Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle Size 7 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.125" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.063" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser | 0000000 | 00000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.094" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.125" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.063" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.094" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.125" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||