Filter by

Thread Size

Nut Type

Thread Direction

Thread Type

Length

Travel Distance per Turn

Diameter

Dynamic Thrust Load Capacity

External Thread Size

Hardness

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Precision Acme Lead Screws and Nuts

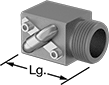

Externally Threaded Nuts—Right-Hand Thread

|

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

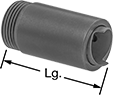

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360 Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.05" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 141 | 50,000 | 310 | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 1,250 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.166" | 1"-18 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.125" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.063" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.125" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 141 | 50,000 | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-10 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.1" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 141 | 50,000 | 11,250 | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

673 Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Stub Acme | 1:1 | 1 | 0.125" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Stub Acme | 1:1 | 1 | 0.1" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.083" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 1" | 1.125" | Acme | 1:1 | 1 | 0.2" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 1:1 | 1 | 0.125" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.167" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8"-6 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.167" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.167" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-4 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-5 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-4 | 2 3/4" | 2.75" | Acme | 1:1 | 1 | 0.25" | 2 35/64"-18 | 7/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-5 | 2 3/4" | 2.75" | Acme | 1:1 | 1 | 0.2" | 2 35/64"-18 | 7/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2"-4 | 3 3/8" | 3.375" | Acme | 1:1 | 1 | 0.25" | 3 9/64"-12 | 1 9/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.125" | 1"-18 | 1/2" | Acme Class 2C | Rockwell R120 | 8,000 | 1,400 | -40 to 190 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.063" | 1"-18 | 1/2" | Acme Class 2C | Rockwell R120 | 8,000 | 1,400 | -40 to 190 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.125" | 1 3/8"-16 | 1/2" | Acme Class 2C | Rockwell R120 | 8,000 | 2,500 | -40 to 190 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-10 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.1" | 1 31/32"-18 | 13/16" | Acme Class 2C | Rockwell R120 | 8,000 | 5,600 | -40 to 190 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.05" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.125" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.1" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.083" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 1:1 | 1 | 0.125" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,000 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.167" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.167" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Not Rated | Not Rated | 3,900 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Not Rated | Not Rated | 6,000 | 15 to 175 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-4 | 3 15/32" | 2.75" | Acme | 1:1 | 1 | 0.25" | 2 35/64"-18 | 7/8" | Acme Class 2C | Not Rated | Not Rated | 10,000 | 15 to 175 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.05" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | 16,000 | 150 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 620 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 1,400 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.166" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 1,400 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 1,400 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 2,500 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 2,500 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | 16,000 | 2,500 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Not Rated | 16,000 | 3,900 | -40 to 525 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Nuts—Left-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360 Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.125" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 2,800 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-16 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.063" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 2,800 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-8 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.125" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | 5,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-10 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.1" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | 11,250 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

673 Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.063" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 1:1 | 1 | 0.083" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-5 | 1" | 1.125" | Acme | 1:1 | 1 | 0.2" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 1:1 | 1 | 0.125" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-10 | 1" | 1.125" | Acme | 1:1 | 1 | 0.1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-5 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.2" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.167" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1 1/4" | 1.125" | Acme | 1:1 | 1 | 0.1" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.25" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-5 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.2" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.167" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Acme | 1:1 | 1 | 0.1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-4 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4"-5 | 1 3/4" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.25" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-5 | 2 19/64" | 2.125" | Acme | 1:1 | 1 | 0.2" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2"-4 | 2 3/4" | 2.75" | Acme | 1:1 | 1 | 0.25" | 2 35/64"-18 | 7/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

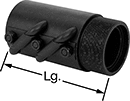

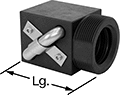

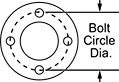

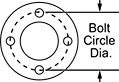

Flanges

|

|

Flange Thread Size | Flange Dia. | Flange Thk. | Bolt Circle Dia. | Flange Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 156 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 156 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 9/64"-12 | 5 3/8" | 1 37/64" | 4 3/8" | Brinell 156 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 135 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 39/64" | 17/32" | 2 3/32" | Brinell 135 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 135 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 135 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1215 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 140 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 35/64"-18 | 4 15/16" | 29/32" | 4 1/16" | Brinell 140 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

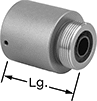

Fast-Travel Precision Acme Lead Screws and Nuts

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360 Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-16 | 5/8" | 0.688" | Acme | 4:1 | 4 | 0.25" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 130 | Not Rated | 300 | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 2:1 | 2 | 0.25" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 1,900 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 2:1 | 2 | 0.25" | 1"-18 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 2,800 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.5" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.333" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 5,000 | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

673 Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-12 | 5/8" | 0.688" | Stub Acme | 4:1 | 4 | 0.333" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Stub Acme | 2:1 | 2 | 0.25" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Stub Acme | 4:1 | 4 | 0.5" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Stub Acme | 2:1 | 2 | 0.2" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.167" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-8 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.25" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-8 | 3/4" | 1.125" | Stub Acme | 8:1 | 8 | 1" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.2" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Stub Acme | 5:1 | 5 | 0.5" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 2:1 | 2 | 0.333" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 4:1 | 4 | 0.5" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Stub Acme | 10:1 | 10 | 1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 2:1 | 2 | 0.5" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | — | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PET | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-12 | 5/8" | 0.688" | Acme | 4:1 | 4 | 0.333" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 160 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-5 | 5/8" | 0.688" | Acme | 5:1 | 5 | 1" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 250 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.25" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-8 | 5/8" | 0.688" | Acme | 4:1 | 4 | 0.5" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-10 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.2" | 9/16"-18 | 3/8" | Acme Class 2C | Not Rated | Not Rated | 350 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-8 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.25" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 2:1 | 2 | 0.2" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-10 | 3/4" | 1.125" | Acme | 5:1 | 5 | 0.5" | 15/16"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 650 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 4:1 | 4 | 0.5" | 1"-18 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 1,450 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.5" | 1 3/8"-16 | 1/2" | Acme Class 2C | Not Rated | Not Rated | 2,500 | 15 to 175 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Nuts—Left-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Tensile Strength | Dynamic Thrust Load Cap., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360 Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-8 | 1" | 1.125" | Acme | 2:1 | 2 | 0.25" | 15/16"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 1,900 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-8 | 1 1/4" | 1.125" | Acme | 2:1 | 2 | 0.25" | 1"-18 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 2,800 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.5" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 5,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-6 | 1 1/2" | 1.5" | Acme | 2:1 | 2 | 0.333" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 130 | Not Rated | 5,000 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

673 Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-12 | 5/8" | 0.688" | Acme | 2:1 | 2 | 0.167" | 9/16"-18 | 3/8" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-6 | 1 1/4" | 1.125" | Acme | 2:1 | 2 | 0.333" | 1"-18 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-10 | 1 1/2" | 1.5" | Stub Acme | 10:1 | 10 | 1" | 1 3/8"-16 | 1/2" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2"-4 | 2 19/64" | 2.125" | Acme | 2:1 | 2 | 0.5" | 1 31/32"-18 | 13/16" | Acme Class 2C | Brinell 70 | Not Rated | Not Rated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanges

|

|

Flange Thread Size | Flange Dia. | Flange Thk. | Bolt Circle Dia. | Flange Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

1117 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 156 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1215 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

303 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 140 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric Precision Lead Screws and Nuts

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Dia. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Thread Fit | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Manganese Bronze | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 × 2 mm | 5/8" | 0.68" | Metric Trapezoidal | 1:1 | 1 | 2 | 9/16"-18 | 3/8" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 670 | DIN 103 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 × 3 mm | 3/4" | 1.125" | Metric Trapezoidal | 1:1 | 1 | 3 | 15/16"-16 | 1/2" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 1,100 | DIN 103 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 × 3 mm | 1" | 1.125" | Metric Trapezoidal | 1:1 | 1 | 3 | 15/16"-16 | 1/2" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 2,000 | DIN 103 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M20 × 4 mm | 1 1/4" | 1.125" | Metric Trapezoidal | 1:1 | 1 | 4 | 1"-18 | 1/2" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 3,100 | DIN 103 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M24 × 5 mm | 1 1/2" | 1.5" | Metric Trapezoidal | 1:1 | 1 | 5 | 1 3/8"-16 | 1/2" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 4,500 | DIN 103 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M28 × 5 mm | 1 3/4" | 2.125" | Metric Trapezoidal | 1:1 | 1 | 5 | 1 31/32"-18 | 13/16" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 6,100 | DIN 103 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M40 × 7 mm | 2 19/64" | 2.125" | Metric Trapezoidal | 1:1 | 1 | 7 | 1 31/32"-18 | 13/16" | Metric Trapezoidal Class 7H | Brinell 126 | 75,000 | 12,300 | DIN 103 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

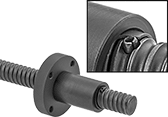

Ball Screws and Nuts

Externally Threaded Ball Nuts—Right-Hand Threaded

Ball Screw Nuts | Wipers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-8 | 1" | — | — | 3/4" | 1 | 0.125" | 11/16"-28 | Rockwell C56 | 170 | 0.015" | -65 to 300 | 00000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8"-5 | 1 45/64" | 1" | 1" | — | 1 | 0.2" | 15/16"-16 | Rockwell C56 | 820 | 0.015" | -65 to 300 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/4"-5 | 2 7/8" | — | — | 1 1/4" | 1 | 0.2" | 1 1/8"-18 | Rockwell C56 | 1,900 | 0.015" | -65 to 300 | 00000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2"-2 | 5 9/16" | — | — | 2 5/8" | 1 | 0.5" | 2 23/64"-18 | Rockwell C56 | 12,900 | 0.015" | -65 to 300 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2"-4 | 3" | — | — | 2 3/32" | 1 | 0.25" | 1 31/32"-18 | Rockwell C56 | 4,250 | 0.015" | -65 to 300 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 1/4"-2 | 6 11/16" | — | — | 3 3/8" | 1 | 0.5" | 3.137"-12 | Rockwell C58 to Rockwell C62 | 21,306 | 0.015" | -65 to 300 | 00000000 | 00000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1"-4 | 2 11/32" | 1 1/2" | 1 1/2" | — | 1 | 0.25" | 1 9/16"-18 | Rockwell C56 | 1,625 | 0.015" | -65 to 300 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Externally Threaded Ball Nuts—Left-Hand Threaded

Style | Thread Size | Lg. | Wd. | Ht. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8"-5 | 1 45/64" | 1" | 1" | 1 | 0.2" | 15/16"-16 | Rockwell C56 | 820 | 0.015" | -65 to 300 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1"-4 | 2 11/32" | 1 1/2" | 1 1/2" | 1 | 0.25" | 1 9/16"-18 | Rockwell C56 | 1,620 | 0.015" | -65 to 300 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fast-Travel Ball Screws and Nuts

|  |  |  |  |

Ball Nuts, Externally Threaded Nut, Style A | Ball Nuts, Externally Threaded Nut, Style B | Ball Nuts, Externally Threaded Nut, Style C | Ball Nuts, Externally Threaded Nut, Style D |

Externally Threaded Ball Nuts—Right-Hand Threaded

Ball Screw Nuts | Wipers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M12 | 50 mm | — | — | 30 mm | 1 | 10 mm | M25 | Rockwell C56 | 1,000 | 0.02 mm | 32 to 150 | 00000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M16 | 50 mm | — | — | 39 mm | 4 | 16 mm | M30 | Rockwell C56 | 1,500 | 0.04 mm | 32 to 150 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M32 | 90 mm | — | — | 53 mm | 4 | 32 mm | M50 | Rockwell C56 | 3,700 | 0.03 mm | 32 to 150 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1/2"-4 | 1 3/4" | — | — | 1 1/16" | 2 | 0.5" | 15/16"-16 | Rockwell C56 | 850 | 0.015" | -65 to 300 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/4"-4 | 2 15/16" | — | — | 1 5/16" | 2 | 0.5" | 1 1/4"-16 | Rockwell C56 | 3,400 | 0.015" | -65 to 300 | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1"-4 | 3 1/8" | — | — | 1 11/16" | 2 | 0.5" | 1 9/16"-18 | Rockwell C56 | 4,250 | 0.015" | -65 to 300 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 1/2"-2 | 3 3/4" | 2 1/4" | 2 1/4" | 2 5/8" | 2 | 1" | 2 1/4"-20 | Rockwell C56 | 8,000 | 0.015" | -65 to 300 | 00000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 1"-4 | 3" | 1 1/2" | 1 1/2" | — | 4 | 1" | 1 9/16"-18 | Rockwell C56 | 2,300 | 0.015" | -65 to 300 | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric Fast-Travel Ultra-Precision Lead Screws and Nuts

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Hex Wd. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M2 × 0.5 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 2:1 | 2 | 1 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 10 | -40 to 185 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M4 × 1.25 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 8:1 | 8 | 10 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 25 | -40 to 185 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M5 × 1.25 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 4:1 | 4 | 5 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 25 | -40 to 185 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M8 × 2 mm | 1" | — | — | 0.548" | 11/16" | Metric Rounded Trapezoidal | 2:1 | 2 | 4 | 5/8"-18 | 1/4" | Not Rated | 8,000 | 75 | -40 to 185 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 2:1 | 2 | 0.75 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 4:1 | 4 | 1.5 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 8:1 | 8 | 3 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M3 × 0.5 mm | 13/32" | 0.311" | 0.276" | — | — | Metric Rounded Trapezoidal | 2:1 | 2 | 1 | M7 × 0.75 mm | 5/32" | Durometer 83D | Not Rated | 4 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M3 × 0.5 mm | 13/32" | 0.311" | 0.276" | — | — | Metric Rounded Trapezoidal | 6:1 | 6 | 3 | M7 × 0.75 mm | 5/32" | Durometer 83D | Not Rated | 4 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M4 × 1 mm | 1/2" | 0.402" | 0.354" | — | — | Metric Rounded Trapezoidal | 4:1 | 4 | 4 | M9 × 1 mm | 13/64" | Durometer 83D | Not Rated | 4 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | M4 × 1 mm | 1/2" | 0.402" | 0.354" | — | — | Metric Rounded Trapezoidal | 8:1 | 8 | 8 | M9 × 1 mm | 13/64" | Durometer 83D | Not Rated | 10 | — | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metric Ultra-Precision Lead Screws and Nuts

Externally Threaded Nuts—Right-Hand Thread

External Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | Hex Wd. | Thread Type | Speed Ratio | No. of Thread Starts | Travel Distance per Turn, mm | Size | Lg. | Hardness | Tensile Strength, psi | Dynamic Thrust Load Cap., lb. | Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M2 × 0.5 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 10 | -40 to 185 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M4 × 0.3 mm | 11/16" | — | — | 0.297" | 7/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 0.3 | 3/8"-24 | 3/16" | Not Rated | 8,000 | 25 | -40 to 185 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | M8 × 1.5 mm | 1" | — | — | 0.548" | 11/16" | Metric Rounded Trapezoidal | 1:1 | 1 | 1.5 | 5/8"-18 | 1/4" | Not Rated | 8,000 | 75 | -40 to 185 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M2 × 0.4 mm | 5/16" | 0.22" | 0.197" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 0.375 | M5 × 0.8 mm | 9/64" | Durometer 83D | Not Rated | 2 | — | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M3 × 0.5 mm | 13/32" | 0.311" | 0.276" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 0.5 | M7 × 0.75 mm | 5/32" | Durometer 83D | Not Rated | 5 | — | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | M4 × 1 mm | 1/2" | 0.402" | 0.354" | — | — | Metric Rounded Trapezoidal | 1:1 | 1 | 1 | M9 × 1 mm | 13/64" | Durometer 83D | Not Rated | 10 | — | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Self-Stopping Ball Screws and Nuts

Externally Threaded Ball Nuts—Right-Hand Threaded

Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Black-Oxide Alloy Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-6 | 1 7/8" | 1" | 2 | 0.188" | 15/16"-16 | Rockwell C56 | 300 | 0.006" | -65 to 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1"-4 | 2 23/32" | 1 5/8" | 2 | 0.274" | 1.563"-18 | Rockwell C56 | 900 | 0.008" | -65 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Ball Screws and Nuts

Externally Threaded Ball Nuts—Right-Hand Threaded

Style | Thread Size | Lg. | Wd. | Ht. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/8"-8 | 1" | — | — | 3/4" | 1 | 0.125" | 0.664"-32 | Rockwell C38 | 25 | 0.007" | -65 to 300 | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5/8"-5 | 1 23/32" | 1" | 1" | — | 1 | 0.2" | 15/16"-16 | Rockwell C38 | 170 | 0.007" | -65 to 300 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fast-Travel Corrosion-Resistant Ball Screws and Nuts

Externally Threaded Ball Nuts—Right-Hand Threaded

Thread Size | Lg. | Dia. | No. of Thread Starts | Travel Distance per Turn | External Thread Size | Hardness | Dynamic Thrust Load Cap., lb. | Max. Backlash | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

17-4 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-4 | 1 3/4" | 1 1/16" | 2 | 0.5" | 15/16"-16 | Rockwell C38 | 140 | 0.007" | -65 to 300 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-4 | 2 15/16" | 1 5/16" | 2 | 0.5" | 1 1/4"-16 | Rockwell C38 | 600 | 0.007" | -65 to 300 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||