How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About On/Off Valves

More

Stainless Steel Measuring Spoon Sets

| Number of Spoons | Capacity | Lg. | Graduation Marks | Material | Autoclavable | Each | ||

| A | 4 | 1/4 tsp., 1/2 tsp., 1 tsp., 1 tbsp. (1.25 ml, 2.5 ml, 5 ml, 15 ml) | 5 1/4" | __ | 304 Stainless Steel | Yes | 0000000 | 00000 |

| B | 4 | 1 tsp., 2 tsp., 1 tbsp., 2 tbsp. (5 ml, 10 ml, 15 ml, 30 ml) | 4" | __ | 304 Stainless Steel | Yes | 0000000 | 00000 |

| C | 4 | 1/4 cup, 1/3 cup, 1/2 cup, 1 cup (60 ml, 80 ml, 120 ml, 240 ml) | 6 1/4" | 1/4 cup, 60 ml | 304 Stainless Steel | Yes | 0000000 | 00000 |

Plastic Spoons

For technical drawings and 3-D models, click on a part number.

| Capacity, ml | Lg. | Material | Color | Autoclavable | Max. Temperature, °F | Specifications Met | Each | |

| 1 | 7" | Polypropylene Plastic | White | Yes | 275° | FDA Compliant 21 CFR 177.1520 | 00000000 | 00000 |

| 2 | 7" | Polypropylene Plastic | White | Yes | 275° | FDA Compliant 21 CFR 177.1520 | 00000000 | 0000 |

| 5 | 7" | Polypropylene Plastic | White | Yes | 275° | FDA Compliant 21 CFR 177.1520 | 00000000 | 0000 |

| 15 | 7" | Polypropylene Plastic | White | Yes | 275° | FDA Compliant 21 CFR 177.1520 | 00000000 | 0000 |

Metal- and X-Ray-Detectable Plastic Measuring Spoon Sets

Measure ingredients for your food processing line. To help you comply with Hazard Analysis and Critical Control Point (HACCP) programs, these spoons contain metal and chemical additives that make them set off metal detectors and show up on X-ray machines. They’re also bright blue, so workers can easily spot broken pieces that fall into your line. Made of polypropylene, they’re lighter than metal spoons and won’t scratch surfaces. These spoons are FDA compliant for direct contact with food.

| Number of Spoons | Capacity | Lg. | Material | Color | Autoclavable | Max. Temperature, °F | Specifications Met | Each | ||

| A | 4 | 1/2 tsp., 1 tsp., 2 tsp., 1 tbsp. (2.5 ml, 5 ml, 10 ml, 15 ml) | 4 1/2" | Polypropylene Plastic | Blue | No | 212° | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297 | 0000000 | 000000 |

| B | 4 | 1/4 cup, 1/3 cup, 1/2 cup, 1 cup (60 ml, 80 ml, 125 ml, 250 ml) | 6 1/2" | Polypropylene Plastic | Blue | No | 212° | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.2010, FDA Compliant 21 CFR 178.3297 | 0000000 | 00000 |

Plastic Spoon Sets

For technical drawings and 3-D models, click on a part number.

| Number of Spoons | Capacity, ml | Lg. | Material | Color | Autoclavable | Max. Temperature, °F | Specifications Met | Each | |

| 4 | 1, 2, 5, 15 | 7" | Polypropylene Plastic | White | Yes | 275° | FDA Compliant 21 CFR 177.1520 | 00000000 | 00000 |

Stainless Steel Dippers

| Capacity, fl. oz. | Bowl Dia. | Handle Lg. | Material | Autoclavable | Each | |

| 16 | 4" | 36" | 304 Stainless Steel | No | 0000000 | 0000000 |

Plastic Dippers for Harsh Chemicals

Made from PTFE plastic, these dippers are more chemical resistant than other plastic dippers.

For technical drawings and 3-D models, click on a part number.

Sterile Disposable Dippers

Each dipper comes individually bagged and sterilized.

For technical drawings and 3-D models, click on a part number.

| Capacity, fl. oz. | Bowl Dia. | Handle Lg. | Material | Lid Material | Seal Material | Color | Max. Temperature, °F | Features | Each | |

| 1 | 1" | 15" | Polystyrene Plastic | Polypropylene Plastic | __ | Clear | 155° | Removable Handle | 0000000 | 00000 |

| 3 3/8 | 1 3/4" | 15" | Polystyrene Plastic | Tin-Plated Steel | PVC Plastic | Clear | 155° | Removable Handle | 0000000 | 0000 |

| 8 1/2 | 2 3/8" | 13" | Polystyrene Plastic | Tin-Plated Steel | PVC Plastic | Clear | 155° | Removable Handle | 0000000 | 0000 |

Design-Your-Own Extra-Long-Reach Liquid Samplers

Choose a telescoping handle and a snap-on bottle or beaker to collect samples from large tanks and vats.

Polypropylene containers adjust up to 90° so they stay horizontal while sampling.

| Capacity, ml | Overall Dia. | Strap Material | Color | Autoclavable | Max. Temperature, °F | Features | Each | |

Polypropylene Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 750 | 3 1/2" | Nylon Plastic | Semi-Clear White | No | 140° | Threaded Lid | 0000000 | 0000000 |

Liquid Samplers

Collect liquid samples from drums, tanks, and other containers.

Stainless steel samplers open and close by pulling up on the center ring.

Press the button on the end of the PTFE samplers to let liquid flow in, and then release it to close.

Disposable Samplers for Thick Liquids

Extract samples of thick liquids, such as oil, with a maximum viscosity of 100 cP.

Overall | ||||||

|---|---|---|---|---|---|---|

| Capacity, ml | Max. Viscosity, cP | Dia. | Lg. | Max. Temperature, °F | Each | |

Polyethylene Plastic | ||||||

| 200 | 100 | 7/8" | 39 1/2" | 140° | 0000000 | 000000 |

Sterile Disposable Samplers for Thick Liquids

This sampler is cleaned and bagged in a Class 7 clean room. Each bag is marked with a lot number. Use this sampler to extract thick liquids, such as oil, with a maximum viscosity of 100 cP.

Overall | ||||||

|---|---|---|---|---|---|---|

| Capacity, ml | Max. Viscosity, cP | Dia. | Lg. | Max. Temperature, °F | Each | |

Polyethylene Plastic | ||||||

| 200 | 100 | 7/8" | 39 1/2" | 140° | 0000000 | 000000 |

Liquid Samplers for Extra-Large Tanks

Lower these samplers with a chain or cable to collect samples from the bottom of large tanks. Also known as bomb samplers, they open automatically when they touch the bottom of the tank or they can be opened manually with a pull line.

Vacuum Samplers for Liquids

Pump the handle to draw liquid out of a tank or drum through a hose into sample bottles. Only the hose and hose weight come into contact with the liquid, reducing the possibility of cross contamination.

Bottle | Hose | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. of Bottles | Cap., ml | Ht. | Wd. | Dp. | Material | ID | OD | Lg., ft. | Material | Weight Material | Pump Material | Max. Temp., °F | Includes | Each | |

| 10 | 100 | 4 1/4" | 1 3/4" | 1 3/4" | Polyethylene Plastic | 0.24" | 0.31" | 32 | Polyethylene Plastic | 304 Stainless Steel | Polyethylene Plastic | 140° | 20 Tamper Seal Labels, Hose Cutter, Case | 0000000 | 0000000 |

Sludge Samplers

Closed

with Sample

Collect and measure buildup from the bottom of oil tanks, septic tanks, wastewater lagoons, and other areas. Unlike other samplers that only hold liquids, these samplers can draw in solids, too. They help you monitor sludge, which is important for maintaining healthy heating systems and meeting environmental regulations for sewage. Not for use with ethanol or ethanol-blended fuel.

Made of a strong plastic, these samplers are rigid enough to push through tough layers of sludge to collect a complete sample. A valve lets in liquids and solids, then blocks them from going out. Samplers are clear and marked with 1-ft. graduations, so you can view and measure what’s inside. Press down on the valve pin to empty.

These samplers consist of three hollow 5-ft. tubes. Screw together as many as you need to match the depth of your tank. Since they’re detachable, they’re easy to transport. Add extensions (sold separately) to make samplers longer.

Stainless Steel Spoons and Lab Spatulas

Each | ||||||||

|---|---|---|---|---|---|---|---|---|

| Capacity, ml | Lg. | Material | Autoclavable | Specifications Met | Features | Each | ||

Spoon | ||||||||

| A | 37 | 11" | 400 Series Stainless Steel | Yes | FDA Compliant 21 CFR 177.1500, NSF/ANSI 2 | __ | 0000000 | 00000 |

| A | 37 | 18" | 400 Series Stainless Steel | Yes | FDA Compliant 21 CFR 177.1500, NSF/ANSI 2 | __ | 0000000 | 0000 |

| B | 60 | 14" | 300 Series Stainless Steel | No | NSF/ANSI 2 | Insulated Plastic Grip | 0000000 | 00000 |

Spoon × Squared Spatula | ||||||||

| G | 1.7 | 6" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

| G | 1.7 | 8 1/4" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

| G | 9 | 15 3/4" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

Spoon × Spoon | ||||||||

| H | 2 × 0.5 | 6" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

| H | 2.8 × 0.8 | 7 1/4" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

| H | 5 × 1.6 | 8 1/4" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

| H | 8 × 5 | 12" | 304 Stainless Steel | Yes | __ | __ | 00000000 | 00000 |

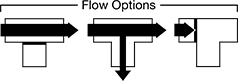

Sampling Valves for Fuel

- Valve Type: Ball

- For Use With: Butane, Diesel Fuel, Fuel Oil, Gasoline, Kerosene, Propane

- Seal Material: Graphite

- Specifications Met: American Petroleum Institute Standard 607, Edition 5

Fire-tested to meet American Petroleum Institute (API) 607, Edition 5, these valves are designed to securely isolate fluid and prevent the spread of fire. They’re often installed on petroleum loading arms to drain a small amount of fuel for inspection without interrupting flow. Turn the handle to divert a small amount of media to the sampling outlet or to shut off flow. Body is 316 stainless steel for excellent corrosion resistance. All valves are full port, so they do not restrict flow.

| Pipe Size | Flow Pattern | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

NPT Female × NPT Male—NPT Female Bottom Sampling Outlet | ||||||

|---|---|---|---|---|---|---|

316 Stainless Steel Body | ||||||

| 1/2 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 4 1/16" | 000000 | 0000000 |

| 3/4 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 4 11/16" | 000000 | 000000 |

| 1 | T-Pattern | 6000 psi @ 100° F | -40° to 600° | 5 3/8" | 000000 | 000000 |

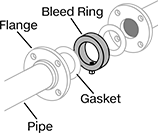

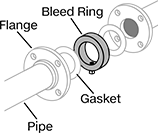

Stainless Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Create an access point in a pipe line where corrosion is a concern. Often used to relieve pressure or siphon and sample liquids, these bleed rings act as a port between two pipe flanges, eliminating the need to take apart your flanges to get inside. They include a plug, or replace the plug with your own fitting, valve, or probe. Made of stainless steel, these bleed rings resist rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

304 stainless steel bleed rings keep corrosion at bay in wet conditions but will start to corrode when exposed to salt water. 316 stainless steel bleed rings withstand wet conditions as well as chemicals and salt water.

For technical drawings and 3-D models, click on a part number.

Plug | 304/304L Stainless Steel | 316/316L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | Each | ||

For Flange Class 125 or 150 | ||||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

For Flange Class 300 | ||||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 | 000000 | 00 |

For Flange Class 600 | ||||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 | 0000000 | 000000 |

Steel Bleed Rings

- For Use With: Air, Natural Gas, Oil, Steam, Water

Access the inside of a pipe line to vent pressure, drain liquid, or take samples. These bleed rings act as a port where two pipe flanges meet, so you don’t have to disassemble your flanges to get inside. They include a plug, or you can attach your own fitting, valve, or probe. Made of steel, these bleed rings should be used in noncorrosive environments to prevent rusting.

Install these bleed rings between two pipe flanges along with a gasket on both sides to avoid leaks. They’re designed to fit flanges that meet ASME B16.5.

For technical drawings and 3-D models, click on a part number.

Plug | Steel | |||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Width | Wall Thickness | Pipe Size | Thread Type | Each | |

For Flange Class 125 or 150 | ||||||||

| 2 | 4" | 2.375" | 1.5" | 0.813" | 1/2 | NPT | 0000000 | 0000000 |

| 3 | 5 1/4" | 3.5" | 1.5" | 0.875" | 1/2 | NPT | 0000000 | 000000 |

| 4 | 6 3/4" | 4.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 8 5/8" | 6.625" | 1.5" | 1" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 300 | ||||||||

| 4 | 7" | 4.5" | 1.5" | 1.25" | 1/2 | NPT | 0000000 | 000000 |

| 6 | 9 3/4" | 6.625" | 1.5" | 1.563" | 1/2 | NPT | 0000000 | 000000 |

For Flange Class 600 | ||||||||

| 2 | 4 1/4" | 2.375" | 1.5" | 0.938" | 1/2 | NPT | 0000000 | 000000 |

| 3 | 5 3/4" | 3.5" | 1.5" | 1.125" | 1/2 | NPT | 0000000 | 000000 |

Digital Weighing Spoons

Weigh liquids, powders, or crystals as you transfer them from one container to another with these spoons. A digital screen on the handle displays the weight of your material to the nearest 0.1 g or 0.005 oz. For measuring volume, the head is marked in 5-ml increments up to 30 ml. Head is corrosion resistant and can be removed from the handle for cleaning. Spoons include a traceable calibration certificate to NIST standards.

Capacity | Graduations | Accuracy | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| oz. | g | ml | oz. | g | ml | oz. | g | Overall Lg. | Material | Batteries Included | Features | Certification | Each | |

| 10.58 | 300 | 32 | 0.005 | 0.1 | 5 | ±0.007 | ±0.2 | 9" | ABS Plastic | Yes | Tare Function | Calibration Certificate with Test Data Traceable to NIST | 0000000 | 000000 |