About Vacuum Pumps

More

About Air Compressors

More

Oil-Free Electric Vacuum Pumps

Generate a vacuum with no risk of oil contamination in your system. These pumps can also create compressed air for powering tools and controlling fluid motion. In vacuum generation, the maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum.

Style A pumps withstand harsh operating conditions. Use them to service machinery, refrigeration systems, and circulation systems. As compressors, they can power pneumatic tools.

Style B pumps are often used for air and gas sampling, controlling compressed air flow, and vacuum filtration. They are also suitable for pressure applications up to 18 psi, such as light pick-and-place operations.

Style C and D pumps are often used for aeration, leak detection, and liquid-level control. As compressors, they can apply protective coatings or dispense adhesives in exact amounts.

Threaded connections are secure and leak resistant. They’re ideal for permanent or semi-permanent installations. Barbed connections join quickly and easily in tight spaces with no threading or sealant needed.

Intake | Discharge | O'all | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Pipe Size | Thread Type | Gender | Connection Style | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | ||||||||||||||||||||

| A | 27.5 | 1.75 | 50 | 35° to 100° | 70 | 1/6 hp | 3.5 | Threaded | 1/4 | NPT | Female | Threaded | 1/4 | NPT | Female | 11 1/2" | 5 5/8" | 8 5/8" | 000000 | 0000000 |

Intake | Discharge | O'all | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Pipe Size | Thread Type | Gender | Connection Style | Pipe Size | Thread Type | Gender | Wire Lead Lg. | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | |||||||||||||||||||||

| A | 27.5 | 5 | 50 | 35° to 100° | 75 | 1/2 hp | 6/12 | Threaded | 1/4 | NPT | Female | Threaded | 1/4 | NPT | Female | __ | 13 1/4" | 12 3/8" | 9" | 000000 | 000000000 |

Hardwire | |||||||||||||||||||||

| A | 27.5 | 10.5 | 50 | 35° to 100° | 75 | 1 1/2 hp | 10/21 | Threaded | 1/4 | NPT | Female | Threaded | 1/4 | NPT | Female | 6" | 21" | 12 1/4" | 8 1/2" | 000000 | 00000000 |

Intake | Discharge | O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dB | Horsepower | Current, A | Connection Style | For Tube ID | Connection Style | For Tube ID | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | ||||||||||||||||

| B | 20 | 0.6 | 18 | 35° to 100° | 72 | 1/45 hp | 1.2 | Barbed | 3/8" | Barbed | 3/8" | 7 1/4" | 4" | 5 1/2" | 00000000 | 0000000 |

Intake | Discharge | O'all | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Pipe Size | Thread Type | Gender | Connection Style | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Each | |

NEMA 5-15 Plug | ||||||||||||||||||||

| C | 26 | 4.5 | 10 | 30° to 100° | 70 | 1/4 hp | 2.1/4.3 | Threaded | 1/4 | NPT | Female | Threaded | 1/4 | NPT | Female | 14" | 5 5/8" | 6" | 0000000 | 0000000 |

Intake | Discharge | O'all | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure, psi | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Connection Style | Pipe Size | Thread Type | Gender | Connection Style | Pipe Size | Thread Type | Gender | Wire Lead Lg. | Lg. | Wd. | Ht. | Each | |

Hardwire | |||||||||||||||||||||

| D | 26 | 4.5 | 10 | 35° to 100° | 70 | 1/4 hp | 0.7/1.4 | Threaded | 1/4 | NPT | Female | Threaded | 1/4 | NPT | Female | 6" | 14 3/8" | 8 1/4" | 6 1/4" | 000000 | 000000000 |

Portable Oil-Free Electric Vacuum Pumps

Create a vacuum for on-site sampling, atomizing, and filtration, or generate compressed air for power tools when and where you need it. Since these pumps don't require lubrication, there’s no risk of oil contamination. Their barbed connections join quickly and easily in tight spaces—no threading or sealant needed. In vacuum generation, maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum.

Repair kits include filter/muffler components, a gasket, a leaf valve, limiters, and an O-ring.

Pumps | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake | Discharge | Overall | Repair Kits | |||||||||||||||

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Max. Pressure , psi | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Tube Connection Type | For Tube ID | Tube Connection Type | For Tube ID | Wire Lead Lg., ft. | Lg. | Wd. | Ht. | Each | Each | ||

120V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

NEMA 5-15 Plug | ||||||||||||||||||

| 25.5 | 1.1 | 60 | 35° to 100° | 65 | 1/8 hp | 4.2 | Barbed | 3/8" | Barbed | 3/8" | __ | 7 3/4" | 5 7/8" | 11" | 0000000 | 0000000 | 0000000 | 000000 |

240V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||||

Hardwire | ||||||||||||||||||

| 25.5 | 1.1 | 60 | 35° to 100° | 65 | 1/8 hp | 2.2 | Barbed | 1/4" | Barbed | 1/4" | 6 | 7 7/8" | 5 1/4" | 11" | 00000000 | 000000 | 0000000 | 00000 |

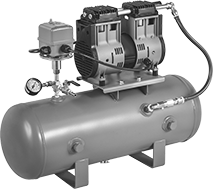

Oil-Free Electric Vacuum Pumps with Tank

Generate a vacuum on demand with these pumps that come mounted on a 10-gal. ASME code vacuum tank for quick startup. They're often used in vacuum-forming applications, such as product packaging. They need no lubrication, so oil won't contaminate your process. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Intake | Discharge | Overall | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Temp. Range, °F | Volume, dBA | Horsepower | Current, A | Tube Connection Type | For Tube ID | Pipe Size | Thread Type | Gender | Lg. | Wd. | Ht. | Includes | Each | |

120V AC, Single Phase—With Thermal Overload Protection | ||||||||||||||||

NEMA 5-15 Plug | ||||||||||||||||

| 26 | 7.1 | 45° to 100° | 58 | 1/3 hp | 4 | Barbed | 3/8" | 3/8 | NPT | Female | 30" | 12 3/8" | 24 1/2" | 10-gal. ASME-Code Vacuum Tank, Muffler, Shut-Off Valve, Three-Position Switch, Vacuum Gauge | 0000000 | 000000000 |

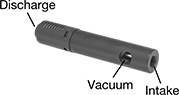

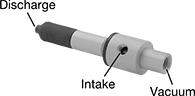

Fixed-Flow Air-Powered Vacuum Pumps

Also known as venturi pumps, these compressed-air-powered pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow. A higher maximum vacuum value indicates a stronger vacuum.

Pumps | Replacement Mufflers | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume | Intake Pipe Size | Discharge Pipe Size | Vacuum Pipe Size | Dia. | Overall Lg. | Each | Each | ||

| 20 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 0000000 | 00000000 | 000000 |

| 20 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 1.4 | 80 | -100° to 400° | 1.4 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 000000 | 000000 | 00000000 | 00000 |

| 20 | 1.4 | 80 | -100° to 400° | 1.4 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 2.1 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 2.1 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 3.5 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 3.5 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 6 | 80 | -100° to 400° | 4.8 | 70 dB | 1/4 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 6 | 80 | -100° to 400° | 4.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 9.5 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 20 | 80 | -100° to 400° | 12.5 | 72 dB | 3/8 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 9 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 20 | 28 | 80 | -100° to 400° | 22 | 76 dB | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1 1/2" | 10 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 26 | 0.95 | 75 | 35° to 125° | 1.6 | 65 dBA | 1/8 NPT | 1/8 NPT | 1/8 NPT | 2" | 5 3/8" | 00000000 | 000000 | 00000000 | 00000 |

| 27 | 2.2 | 75 | 35° to 125° | 3.5 | 65 dBA | 1/8 NPT | 1/4 NPT | 1/4 NPT | 1 3/4" | 7 3/8" | 00000000 | 000000 | 000000 | 00 |

| 27 | 4 | 75 | 35° to 125° | 6.4 | 65 dBA | 1/8 NPT | 3/8 NPT | 3/8 NPT | 1 3/4" | 8 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 0.5 | 80 | -100° to 400° | 0.5 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 0.5 | 80 | -100° to 400° | 0.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 1.2 | 80 | -100° to 400° | 1.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 2 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 BSPP | 1/4 BSPP | 1/8 BSPP | 3/4" | 4 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 2 | 80 | -100° to 400° | 2.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 3.2 | 80 | -100° to 400° | 4.8 | 64 dB | 1/8 NPT | 1/4 NPT | 1/8 NPT | 3/4" | 4 1/4" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 5.4 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 5 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 5.4 | 80 | -100° to 400° | 7.8 | 70 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 5 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 9 | 80 | -100° to 400° | 12.5 | 76 dB | 1/4 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 8 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 20 | 80 | -100° to 400° | 22 | 72 dB | 3/8 BSPP | 3/8 BSPP | 3/8 BSPP | 1 1/4" | 9 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 28 | 20 | 80 | -100° to 400° | 22 | 72 dB | 3/8 NPT | 3/8 NPT | 3/8 NPT | 1 1/4" | 9 7/8" | 0000000 | 000000 | 00000000 | 00000 |

| 28 | 28 | 80 | -100° to 400° | 28 | 76 dB | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1 1/2" | 10 7/8" | 0000000 | 000000 | 00000000 | 00000 |

High-Efficiency Fixed-Flow Air-Powered Vacuum Pumps

A multistage design generates a high vacuum flow with less air consumption than other air-powered vacuum pumps. Also known as venturi pumps, these pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow. A higher maximum vacuum value indicates a stronger vacuum.

Intake | Discharge | Vacuum Connection | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume, dBA | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Dia. | Overall Lg. | Each | |

| 26 | 17 | 68 | 35° to 125° | 7 | 65 | 1/8 | NPT | Female | 3/8 | NPT | Female | 1/2 | NPT | Female | 3" | 10 1/4" | 00000000 | 0000000 |

| 27 | 6.8 | 68 | 35° to 125° | 2.7 | 65 | 1/8 | NPT | Female | 1/4 | NPT | Female | 1/2 | NPT | Female | 3" | 8 1/4" | 00000000 | 000000 |

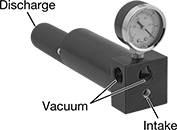

Adjustable-Flow Air-Powered Vacuum Pumps

Use the rotating diffuser to alter flow rate. Also known as venturi pumps, these compressed-air-powered pumps are commonly used in vacuum packaging, pick-and-place operations, and end-of-arm robotic tooling. They have no seals or moving parts that can wear down or overheat, and they don’t require lubrication, so there's no downtime for maintenance. The compact body allows inline installation close to your vacuum point. Maximum flow rate is the rate at which air is pumped before a vacuum is created. Flow rate steadily decreases as the pump generates the vacuum. The larger the tank, the longer it will take to form a vacuum. Tube and fitting ID will also affect flow.

Pumps | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Intake, NPT | Discharge, NPT | Vacuum Connection, NPT | Replacement Mufflers | ||||||||||||||

| Max. Vacuum, in. of Hg | Max. Flow Rate, cfm | Operating Pressure, psi | Temp. Range, °F | Air Consumption, cfm | Volume, dB | Pipe Size | Gender | Pipe Size | Gender | Pipe Size | Gender | Dia. | Overall Lg. | Each | Each | ||

| 25 | 2 | 80 | -100° to 400° | 1.3 | 70 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 0000000 | 00000000 | 000000 |

| 25 | 3.2 | 80 | -100° to 400° | 2.4 | 74 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 6 | 80 | -100° to 400° | 4.7 | 78 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 5 5/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 10 | 80 | -100° to 400° | 8.3 | 84 | 1/8 | Female | 1/4 | Female | 1/4 | Female | 1 1/4" | 6 1/4" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 30 | 80 | -100° to 400° | 17 | 88 | 3/8 | Female | 1/2 | Female | 1/2 | Female | 1 3/4" | 10 7/8" | 00000000 | 000000 | 00000000 | 00000 |

| 25 | 60 | 80 | -100° to 400° | 28 | 82 | 3/8 | Female | 3/4 | Female | 1/2 | Female | 2" | 13" | 00000000 | 000000 | 00000000 | 000000 |

| 25 | 120 | 80 | -100° to 400° | 44 | 98 | 1/2 | Female | 1 | Female | 3/4 | Female | 2 1/4" | 13 7/8" | 00000000 | 000000 | 00000000 | 000000 |

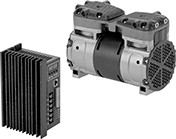

Oil-Free DC Electric Air Compressor/Vacuum Pumps

Generate only as much compressed air or vacuum as you need for precise control in low-flow applications. These pumps deliver a stable output without large fluctuations, so they’re an energy efficient choice. Use a vehicle battery or a DC generator (both not included) to power them. Since they don't require lubrication, there’s no risk of oil contamination in the air.

These pumps come with two ports: one for pressure and one for vacuum. To switch from an air compressor to a vacuum pump, disconnect from the outlet port and connect to the inlet. Make sure the outlet port is open to atmosphere or vented.

Style A pumps are built for rugged environments. Use them in a variety of power applications—from air brakes to septic aeration systems. Since they’re manually actuated and lack a relief valve, you’ll need to monitor their operation to prevent pressure buildup.

Style B pumps generate air for delicate suction and gripping common in robots, medical devices, and industrial automation. A digital pressure switch and relief valve automatically turn them on or off based on pressure levels. Use the included brackets to mount their controller on a 35 mm DIN rail.

Overall | Pipe Size | Controller | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Max. Pressure, psi | Max. Flow Rate @ psi | Vacuum Rating, in. of Hg | hp | Full Load Current, A | Volume, dBA | Lg. | Wd. | Ht. | Temp. Range, °F | Inlet | Outlet | Mounting Location | Ht. | Wd. | Dp. | Lubricant Required | Actuation | Relief Valve | Wire Connection Type | Features | Each | |

24V DC—NPT Female Inlet and Outlet | |||||||||||||||||||||||

| A | 125 | 1.14 cfm @ 125 | 27 | 1/2 | 21.6 | 66 | 9 9/16" | 5" | 7 1/16" | 45° to 100° | 1/4 | 1/4 | Surface | 6 1/2" | 2 5/8" | 4" | No | Manual | Without Relief Valve | Wire Leads | Motor Speed Controller | 00000000 | 000000000 |

24V DC—BSPT Female Inlet and Outlet | |||||||||||||||||||||||

| B | 79 | 0.35 cfm @ 79 | 20 | 1/8 | 4.5 | 55 | 6 1/16" | 3 15/16" | 5 1/4" | 45° to 100° | 1/8 | 1/8 | DIN Rail | 7 1/8" | 4 5/16" | 1 13/16" | No | Pressure, Vacuum | With Relief Valve | Lever-Clamp Terminals | Digital Pressure Switch | 00000000 | 00000000 |

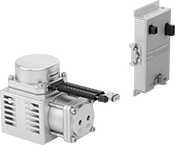

Miniature Oil-Free DC Electric Air Compressor/Vacuum Pumps

Our tiniest option—these DC-powered pumps generate compressed air or vacuum. Their low flow rate makes them a good choice for precise jobs—like medical device or electronics assembly—where too much force could damage components. Since they don't require lubrication, there’s no risk of oil contamination in the air.

These pumps come with two ports: one for pressure and one for vacuum. To switch from an air compressor to a vacuum pump, disconnect from the outlet port and connect to the inlet. Make sure the outlet port is open to atmosphere or vented.

Overall | For Tube ID | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Pressure, psi | Max. Flow Rate @ psi | Vacuum Rating, in. of Hg | Full Load Current, mA | Volume, dBA | Lg. | Wd. | Ht. | Inlet | Outlet | Lubricant Required | Wire Connection Type | Each | |

12V DC | |||||||||||||

| 3 | 0.019 cfm @ 3 0.042 cfm @ 0 | 12 | 40 | 45 | 1 3/4" | 15/16" | 1 5/16" | 0.14" | 0.14" | No | Wire Leads | 0000000 | 0000000 |

| 10 | 0.064 cfm @ 10 0.117 cfm @ 0 | 22 | 442 | 45 | 3 1/16" | 1 3/16" | 2 3/16" | 0.16" | 0.16" | No | Spade Terminals | 0000000 | 000000 |

3.5-7V DC | |||||||||||||

| 2 | 0.008 cfm @ 2 0.013 cfm @ 0 | 12 | 32-37 | 45 | 1 5/8" | 11/16" | 1" | 0.12" | 0.12" | No | Wire Leads | 0000000 | 000000 |

Overall | Pipe Size | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Max. Pressure, psi | Max. Flow Rate @ psi | Vacuum Rating, in. of Hg | Full Load Current, A | Volume, dBA | Lg. | Wd. | Ht. | Inlet | Outlet | Lubricant Required | Wire Connection Type | Each | |

12V DC | |||||||||||||

| 12 | 0.148 cfm @ 12 0.254 cfm @ 0 | 25 | 2.3 | 52 | 4 7/8" | 1 7/8" | 3 1/16" | 1/8 | 1/8 | No | Wire Leads | 0000000 | 0000000 |