How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Actuated On/Off Valves

More

About Gradual On/Off Valves

More

About On/Off Valves

More

Threaded On/Off Valves

Use these valves in general purpose applications such as those with water, oil, air, and inert gas.

Plated brass valves are more corrosion resistant than plain brass or bronze valves.

Lockable handles can be fixed in place using a padlock (not included).

Short lever handles, lockable oval handles, and T-handles resist accidental movement when snagged or bumped.

Full-port valves do not restrict flow.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

- Seal Material:

NPT Female × NPT Female: Fluorocarbon Rubber

NPT Female × NPT Male: PTFE Plastic - Specifications Met: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Specifications Met | Each | |

NPT Female × NPT Female | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 1,305.5 | 450 psi @ 100° F | 150 psi @ 350° F | -40° to 350° | 29.9 | Full | 8 1/2" | CSA Certified, CSA-US Certified | 00000000 | 0000000 |

NPT Female × NPT Male | ||||||||||

| 4 | 1,305.5 | 450 psi @ 100° F | 150 psi @ 365° F | -40° to 350° | 29.9 | Full | 9 3/8" | __ | 00000000 | 000000 |

- Valve Type: Ball

- For Use With:

BSPP: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon

NPT: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam - Seal Material: PTFE Plastic, except NPT Female × NPT Female are Fluorelastomer Rubber

- Specifications Met: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Specifications Met | Each | |

NPT Female × NPT Female | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 1,400 | 450 psi @ 100° F | 150 psi @ 350° F | -40° to 350° | 29.9 | Full | 8 1/2" | 9/32" | CSA Certified, CSA-US Certified | 0000000 | 0000000 |

- Valve Type: Ball

- For Use With: Air, Steam, Water

- Seal Material:

NPT Female × NPT Female: Fluorelastomer Rubber

NPT Female × NPT Male: PTFE Plastic - Specifications Met: See table

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Specifications Met | Each | |

NPT Female × NPT Female | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4 | 1,400 | 450 psi @ 100° F | 150 psi @ 350° F | -40° to 350° | 29.9 | Full | 8 1/2" | 5/16" | CSA Certified, CSA-US Certified | 0000000 | 0000000 |

- Valve Type: Ball

- For Use With: Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Each | |

NPT Female × NPT Female | ||||||||

|---|---|---|---|---|---|---|---|---|

| 4 | 1,622 | 600 psi @ 210° F | -40° to 365° | 29 | Full | 7 5/8" | 00000000 | 0000000 |

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Each | |

NPT Female × NPT Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 4 | 1,622 | 600 psi @ 210° F | -40° to 365° | 29 | Full | 7 5/8" | 9/32" | 0000000 | 0000000 |

- Valve Type: Ball

- For Use With:

BSPP and BSPT: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

NPT and UNF: Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon - Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Ball Material | Each | |

NPT Female × NPT Female | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 4 | 670 | 600 psi @ 100° F | 150 psi @ 365° F | -20° to 450° | Standard | 7 3/8" | Brass | 0000000 | 000000000 |

Easy-Access Threaded On/Off Valves

Extend your reach in hard-to-access areas—turn these valves on and off using a square ratchet to grasp the hole at the end of the handle. They are full port, so they do not restrict flow.

316 stainless steel valves are more corrosion resistant than bronze valves.

Valves with a grease fitting have a built-in lubrication point. Inject lubricant for smooth operation and an extended service life. You can also remove the fitting to drain excess fluid from your valve.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Oil, Water

- Seal Material: PTFE Plastic

Drain | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Pipe Size | Gender | Thread Type | Features | Each | |

Bronze Body | ||||||||||

NPT Female × NPT Female | ||||||||||

| 4 | Not Rated | 400 psi @ 100° F | 35° to 200° | 8" | 1/8 | Female | NPT | Grease Fitting | 0000000 | 0000000 |

316 Stainless Steel Body | ||||||||||

NPT Female × NPT Female | ||||||||||

| 4 | Not Rated | 1000 psi @ 100° F | 35° to 200° | 8 13/16" | 1/8 | Female | NPT | Grease Fitting | 0000000 | 00000000 |

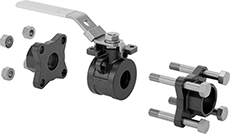

Easy-Maintenance Threaded On/Off Valves

Maintain and repair these valves without unthreading pipe connections. They have a three-piece bolted body that disassembles inline for access to internal components. All are full port, so they do not restrict flow.

316 stainless steel valves are more corrosion resistant than bronze or steel valves.

Lockable lever handles can be fixed in place using a padlock (not included).

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

Valves | Maintenance Kits | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | Each | Each | ||

316 Stainless Steel Body—PTFE Plastic Seal | |||||||||||

NPT Female × NPT Female | |||||||||||

| 4 | 970 | 600 psi @ 220° F | 150 psi @ 365° F | 0° to 450° | Not Rated | 10 13/16" | 1/4" | 00000000 | 000000000 | 0000000 | 0000000 |

Plastic Threaded On/Off Valves

T-handles resist accidental movement when snagged or bumped.

Full-port valves do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With:

Dark Gray PVC Plastic Body: Water

All Other Valves: Air, Argon, Helium, Krypton, Neon, Water, Xenon - Seal Material:

Dark Gray PVC Plastic Body: EPDM Rubber

All Other Valves: Buna-N Rubber

Pipe Size | ||||||||

|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Each | |

Dark Gray PVC Plastic Body | ||||||||

NPT Female × NPT Female | ||||||||

| 4 | 4 | 600 | 150 psi @ 70° F | 40° to 140° | Full | 10 1/16" | 00000000 | 0000000 |

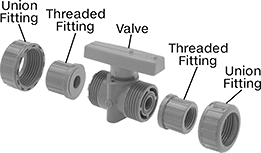

Easy-to-Install Plastic Threaded On/Off Valves

A threaded union on these valves makes them easy to install and remove without disrupting your line. They’re a good choice for lines that require frequent maintenance or cleaning. They thread together or apart with only a turn to the union fitting, unlike other threaded on/off valves that require repositioning your pipe or valve. The union fitting slides over your pipe, and the threaded fitting sits inside. With a full port, these valves won’t restrict flow.

Made of plastic, they last longer than metal valves since the inside won’t corrode or pit. They’re also lighter in weight. PVC valves are commonly used in water lines. CPVC valves handle higher temperatures than PVC or polypropylene valves. They’re the best choice if your system connects to a heater.

Valves with a T-handle have a larger gripping surface than valves with a short lever handle, so they’re easier to turn when your hands are slippery.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With:

PVC Plastic Body: Water, Citric Acid, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Phosphoric Acid, Salt Water, Sulfuric Acid

CPVC Plastic Body: Water, Citric Acid, Hydrochloric Acid, Isopropyl Alcohol, Phosphoric Acid, Salt Water, Sulfuric Acid - Seal Material: EPDM Rubber

| Pipe Size | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Each | |

Dark Gray PVC Plastic Body | |||||||

|---|---|---|---|---|---|---|---|

NPT Female × NPT Female | |||||||

| 4 | 225 psi @ 70° F | 40° to 140° | Not Rated | Full | 13" | 00000000 | 0000000 |

Light Gray CPVC Plastic Body | |||||||

NPT Female × NPT Female | |||||||

| 4 | 225 psi @ 70° F | 40° to 180° | Not Rated | Full | 13" | 00000000 | 000000 |

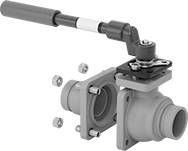

Flanged On/Off Valves

Bolt these valves to ANSI flanges. Their lockable lever handle can be fixed in place using a padlock (not included). All have four mounting holes to install an actuator, so you can convert them from manual to automatic valves.

Steel valves stand up to corrosion better than cast iron valves. 316 stainless steel valves are more corrosion resistant than cast iron and steel valves.

Full-port valves do not restrict flow.Pressure class 150 valves are standard and work for most low-pressure applications.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.5, MSS-SP-72

Bolts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | |||||||||||||

| 4 | 125 | 9" | 7 1/2" | 8 | 0.75" | No | 2,500 | 200 psi @ 150° F | 125 psi @ 215° F | -20° to 350° | 9" | 0000000 | 0000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.5

Bolts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | ||||||||||||||

| 4 | 150 | 9" | 7 1/2" | 8 | 0.75" | No | 2,110 | 275 psi @ 100° F | 100 psi @ 365° F | 0° to 500° | 28 | 9" | 00000000 | 0000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.34, ANSI/ASME B16.5

Bolts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | ||||||||||||||

| 4 | 150 | 9" | 7 1/2" | 8 | 0.75" | No | 2,110 | 275 psi @ 100° F | 100 psi @ 365° F | 0° to 500° | 28 | 9" | 00000000 | 000000000 |

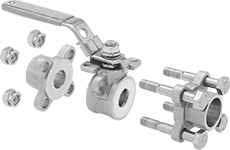

Compact Flanged On/Off Valves

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

- Seal Material: PTFE Plastic

- Specifications Met: ASME B16.34, ASME B16.5, ASME B31.1

Also known as wafer ball valves, these combine the slim body of a butterfly valve with the high flow rates of a flanged ball valve. Bolt these valves to ANSI flanges—they meet ASME standards for dimensions, material, and pressure-temperature rating. They are full port, so they do not restrict flow.

316 stainless steel valves are more corrosion resistant than steel valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Bolts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Thread Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Actuator Mounting Hole Thread Size | Each | |

Steel Body | |||||||||||||||

Flanged × Flanged | |||||||||||||||

| 4 | 150 | 9" | 7 1/2" | 8 | 5/8"-11 | No | 1,577.3 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 6" | M10 | 00000000 | 0000000 |

316 Stainless Steel Body | |||||||||||||||

Flanged × Flanged | |||||||||||||||

| 4 | 150 | 9" | 7 1/2" | 8 | 5/8"-11 | No | 1,577.3 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 6" | M10 | 0000000 | 00000000 |

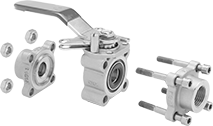

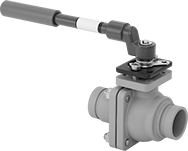

Easy-Maintenance Socket-Connect On/Off Valves

Clean and maintain these valves without removing welded connections. To create a permanent, leak-tight connection, insert unthreaded pipe into the socket and weld. These valves have a three-piece bolted body that disassembles inline, which makes it easy to access internal components. They also have lockable handles that can be fixed in place with a padlock (not included). All are full port, so they do not restrict flow.

316 stainless steel valves resist corrosion better than steel valves.

Lever handles make it easy to see if the valve is open or closed.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Maintenance kits (sold separately) include seats, seals, and stem packing to replace worn parts inside valves.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Neon, Oil

- Seal Material: PTFE Plastic

- Valve Type: Ball

- For Use With:

Socket Connect × Socket Connect: Air, Argon, Helium, Neon, Oil, Steam, Water, Xenon

Socket Connect × NPT Female: Air, Argon, Helium, Neon, Oil, Water, Xenon - Seal Material: PTFE Plastic

On/Off Valves with Grooved-End Fittings

- Valve Type: Ball

- For Use With: Air, Drinking Water, Oil, Water

- Seal Material: PTFE Plastic

- Specifications Met: NSF/ANSI 61, UL Classified, C-UL Classified

For quick and easy access to your line, these valves attach to pipe with a clamp (sold separately) that fits around their grooved ends. No heat or threading required. They’re also known as Victaulic valves. Made of ductile iron, these valves absorb vibration and resist cracking. They’re strong enough for systems with pressure changes and frequent starts and stops. All meet NSF/ANSI 61 for safe use with drinking water. They are full port, so they do not restrict flow. To prevent tampering, lock the handle with a padlock.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Easy-Maintenance Threaded On/Off Valves for Chemicals

- Valve Type: Ball

- For Use With: Carbon Dioxide, Citric Acid, Deionized Water, Ethanol, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Methanol, Methyl Ethyl Ketone, Phosphoric Acid, Salt Water, Sodium Hydroxide, Water

- Ball Material: Polypropylene Plastic

- Seal Material: See table

- Seat Material: PTFE Plastic

No need to remove these valves from your line to access their internal components—the three-piece bolted body comes apart. Ideal in chemical-processing applications, the seal and polypropylene body stand up to aggressive and corrosive solutions.

Valves with a lever handle give you more leverage than valves with T-handles, so you can quickly open and close them with ease. To limit access to your line, replace the handle with a locking handle (sold separately). Fix the handle in place using a padlock (not included) with a shackle diameter up to 19/64".

Valves with a fluoroelastomer seal fit snug even when surfaces are irregular, misaligned, or dirty. The seal compresses and conforms to create a tight, leakproof connection. Standard-port valves slightly restrict flow.

For technical drawings and 3-D models, click on a part number.

Easy-to-Install Threaded On/Off Valves for Chemicals

For fast installation and removal from pipelines, these valves have union fittings that disassemble into multiple pieces. All have a plastic body that can stand up to aggressive and corrosive solutions in chemical-processing applications.

Lockable T-handles can be fixed in place using a padlock (not included) with a shackle diameter up to 1/4".

Full-port valves do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Threaded Union with Lockable

T-Handle (Assembled View)

- Valve Type: Ball

- For Use With: See table

- Ball Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Valves | Union Fittings | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | For Max. Shackle Dia. | For Use With | Each | Pair | ||

Threaded Union × Threaded Union with Lockable T-Handle | ||||||||||

| 4 | 235 psi @ 70° F | 40° to 140° | Full | 12 5/16" | 1/4" | Citric Acid, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Sulfuric Acid, Water | 00000000 | 0000000 | 0000000 | 0000000 |

Threaded Union with Lockable

T-Handle (Assembled View)

- Valve Type: Ball

- For Use With: Citric Acid, Diesel Fuel, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Sodium Hypochlorite, Sulfuric Acid, Water

- Ball Material: CPVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

| Pipe Size | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Threaded Union × Threaded Union with Lockable T-Handle | |||||||

|---|---|---|---|---|---|---|---|

| 4 | 235 psi @ 70° F | 40° to 180° | Full | 12 5/16" | 1/4" | 00000000 | 000000000 |

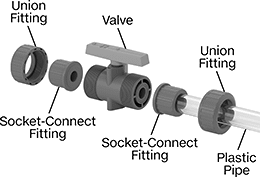

Easy-to-Install Socket-Connect On/Off Valves for Chemicals

Streamline your installation and removal process. These valves give you the leak-tight permanent connection of a socket connect with the ease of fittings that come apart. Before you install the valve, slide the union fitting over your pipe, then insert the pipe into the socket fittings and bond with primer and cement. The union fittings allow the valve to be quickly removed where other socket-connect valves would require you to cut your pipe. A fluoroelastomer seal and plastic body withstand aggressive and corrosive solutions in chemical-processing applications. All valves have a T-handle that resists accidental movement when snagged or bumped. They are full port, so they do not restrict flow.

PVC valves are often used in mild chemical processing systems. CPVC valves resist heat better than PVC valves, so they’re a good choice for systems that connect to a heater. Lockable T-handles can be fixed in place using a padlock (not included).

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Citric Acid, Hydrochloric Acid, Kerosene, Phosphoric Acid, Propane, Salt Water, Water

- Ball Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

| 4 | 40, 80 | 3,104 | 150 psi @ 70° F | 40° to 140° | 26 | 9 13/16" | 0000000 | 0000000 |

- Valve Type: Ball

- For Use With: See table

- Ball Material: PVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Valves | Union Fittings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | For Use With | Each | Pair | ||

| 4 | 40, 80 | 600 | 235 psi @ 70° F | 40° to 140° | Not Rated | 12 5/16" | 1/4" | Citric Acid, Diesel Fuel, Ethylene Glycol, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Phosphoric Acid, Salt Water, Water | 00000000 | 0000000 | 0000000 | 000000 |

- Valve Type: Ball

- For Use With: See table

- Ball Material: CPVC Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Valves | Union Fittings | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | For Use With | Each | Pair | ||

| 4 | 40, 80 | 600 | 235 psi @ 70° F | 40° to 180° | Not Rated | 12 5/16" | 1/4" | Citric Acid, Diesel Fuel, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Phosphoric Acid, Salt Water, Water | 00000000 | 000000000 | 0000000 | 0000000 |

Flanged On/Off Valves for Chemicals

Bolt these valves to ANSI flanges—they meet ASME dimensional standards. They have a plastic body and a seal that withstand aggressive and corrosive solutions in chemical-processing applications.

Glass-filled vinyl ester valves stand up to a wide variety of harsh acids and solvents. You can rely on them for repeated use, changes in pressure and flow rate, and hot and cold conditions.

Valves with a lockable lever handle can be fixed in place with a padlock (not included). They give you more leverage than short lever handles, so you can quickly open and close the valve with minimal effort.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Oil, Phosphoric Acid, Salt Water, Soap Solutions, Toluene, Water, Xylene

- Ball Material: Glass-Filled Vinyl Ester

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Packing Material: PTFE Plastic

- For Flange Specifications Met: ASME B16.5, ASME B16.10

Bolts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Dia. | Included | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Flanged × Flanged | |||||||||||||||

| 4 | 150 | 9" | 7 1/2" | 4 | 3/4" | No | 540 | 150 psi @ 100° F | -50° to 215° | 29.9 | Standard | 9" | 1/4" | 00000000 | 000000000 |

Plastic Threaded On/Off Valves for Drinking Water

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: NSF/ANSI 61

These valves meet NSF/ANSI 61 for use with drinking water. They have a T-handle that resists accidental movement when snagged or bumped. All are full port, so they do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Easy-to-Install Plastic Threaded On/Off Valves for Drinking Water

Disassemble the union fittings on these valves for fast installation and removal from your pipeline. They meet NSF/ANSI 61 for use with drinking water. All have a T-handle that resists accidental movement when snagged or bumped. They are full port, so they do not restrict flow.

Lockable T-handles can be fixed in place using a padlock (not included) with a shackle diameter up to 1/4”.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: NSF/ANSI 61

Valves | Union Fittings | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | Each | Pair | ||

Dark Gray PVC Plastic Body | ||||||||||

NPT Female × NPT Female | ||||||||||

| 4 | 600 | 235 psi @ 70° F | 40° to 140° | 26 | 12 5/16" | 1/4" | 00000000 | 0000000 | 0000000 | 0000000 |

Light Gray CPVC Plastic Body | ||||||||||

NPT Female × NPT Female | ||||||||||

| 4 | 600 | 235 psi @ 70° F | 40° to 180° | 26 | 12 5/16" | 1/4" | 00000000 | 00000000 | 000000 | 00 |

Socket-Connect On/Off Valves for Drinking Water

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: NSF/ANSI 61

Insert unthreaded pipe into the socket ends and bond with primer and cement to create a permanent, leak-tight connection. These valves meet NSF/ANSI 61, which means they’re safe to use with drinking water systems. They are full port, so they do not restrict flow.

PVC valves are made of the standard material used in most drinking water systems. CPVC valves resist heat better than PVC valves, so they’re better for water systems connected to a heater.

T-handles resist accidental movement when snagged or bumped.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Choose a Color | Each | |

PVC Plastic Body with T-Handle | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | |||||||||

| 4 | 40, 80 | 3,129 | 150 psi @ 70° F | 40° to 140° | 26 | 9 3/16" | 0000000 | 0000000 | |

CPVC Plastic Body with T-Handle | |||||||||

Socket Connect × Socket Connect | |||||||||

| 4 | 40, 80 | 3,104 | 150 psi @ 70° F | 40° to 200° | 26 | 9 5/8" | Light Gray | 00000000 | 00000000 |

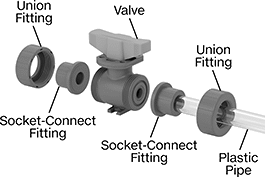

Easy-to-Install Socket-Connect On/Off Valves for Drinking Water

Union ×

Socket-Connect Union

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: NSF/ANSI 61

Ideal for lines that need frequent maintenance, these valves have union fittings that disassemble quickly for removal. To install, slide the union fitting over unthreaded pipe. Insert the pipe into the socket fitting and bond with primer and cement (both not included) to create a permanent, leak-tight connection. When you need to remove the valve, just unthread the union fitting. These valves meet NSF/ANSI 61 for use with drinking water. All have a T-handle that resists accidental movement when snagged or bumped. They are full port, so they do not restrict flow.

PVC valves are made of the standard material used in most drinking water systems. CPVC valves resist heat better than PVC valves. They’re the best choice if your system connects to a heater.

Fix lockable T-handles in place using a padlock (not included).

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Valves | Union Fittings | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | For Max. Shackle Dia. | Each | Pair | ||

Dark Gray PVC Plastic Body with T-Handle | |||||||||||

Socket Connect × Socket-Connect Union | |||||||||||

| 4 | 40, 80 | 3,104 | 150 psi @ 70° F | 40° to 140° | 26 | 9 13/16" | __ | 00000000 | 0000000 | 000000 | 00 |

Dark Gray PVC Plastic Body with Lockable T-Handle | |||||||||||

Socket-Connect Union × Socket-Connect Union | |||||||||||

| 4 | 40, 80 | 600 | 235 psi @ 70° F | 40° to 140° | __ | 12 5/16" | 1/4" | 00000000 | 000000 | 0000000 | 000000 |

Light Gray CPVC Plastic Body with Lockable T-Handle | |||||||||||

Socket-Connect Union × Socket-Connect Union | |||||||||||

| 4 | 40, 80 | 600 | 235 psi @ 70° F | 40° to 190° | __ | 12 5/16" | 1/4" | 00000000 | 00000000 | 0000000 | 000000 |

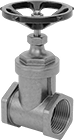

Threaded Gradual On/Off Valves

Also known as gate valves, these valves gradually open and close to prevent system damage from suddenly starting and stopping flow.

Valves with a pull handle open and close faster than valves with a wheel handle. Also known as slide valves, they’re often used to control flow in air conditioning and ventilation systems. Valves with a wheel handle open and close with multiple turns, providing more controlled, shock-resistant flow than valves with a pull handle.

Valves with a rising stem lift the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. Valves with a nonrising stem keep the stem in the same position whether they’re open or closed. They’re often used underground and in low-clearance locations.

Brass valves have good corrosion resistance. They also have a more polished look than bronze valves. However, they’ll corrode from salt water.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Oil, Air, Argon, Helium, Krypton, Neon, Xenon

O'all | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | Stem Housing Connection Style | End-to-End Lg. | Ht. | Lg. | Each | |

NPT Female | |||||||||

| 4 | 685 | 10 psi @ 1000° F | -40° to 1000° | Flanged | 3 5/16" | 14 5/8" | 6" | 0000000 | 0000000 |

- Valve Type: Gate

- For Use With: Water, Oil

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Stem Housing Connection Style | End-to-End Lg. | Ht. | Lg. | Each | |

NPT Female | ||||||||||

Pressure Class 200 | ||||||||||

| 4 | 173 | 200 psi @ 72° F | 120 psi @ 350° F | -20° to 100° | Threaded | 4 1/2" | 12 5/8" | 4 1/2" | 00000000 | 0000000 |

Flanged Gradual On/Off Valves

Nonrising Stem, and

Eight Bolt Holes

Rising Stem, and

Eight Bolt Holes

Rising Stem, and

Eight Bolt Holes

Bolt these valves to flanges. They gradually open and close to prevent system damage from suddenly starting and stopping flow.

Epoxy-coated cast iron valves are more corrosion resistant than plain cast iron or steel valves.

316 stainless steel valves have the best corrosion resistance.

Wheel handles open and close with multiple turns, providing more controlled, shock-resistant flow than pull handles.

Pull handles open and close faster than wheel handles.

Nonrising stems stay in the same position whether the valve is open or closed. Valves with nonrising stems are often used underground and in other low-clearance locations.

Rising stems lift as the valve opens and lower as the valve closes to provide a visual indication of whether flow is on or off. The stem is isolated from the process media for a longer service life than valves with a nonrising stem.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 150° F | 125 psi @ 350° F | -20° to 450° | 9" | 20 1/4" | 9" | 00000000 | 0000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 150° F | 125 psi @ 350° F | -20° to 450° | 9" | 28 1/2" | 9" | 0000000 | 0000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: Graphite

- Specifications Met: American Petroleum Institute Standard 600, ASTM A216 WCB

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 150 | 285 psi @ 100° F | 150 psi @ 365° F | -20° to 800° | 9" | 27 1/2" | 9" | 00000000 | 000000000 |

- Valve Type: Gate

- For Use With: Water, Air

- Specifications Met: ASME B16.10, ASTM A126 Class B, AWWA C509, MSS-SP-70

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 9" | 17" | 9" | 00000000 | 0000000 |

- Valve Type: Gate

- For Use With: Water, Air

- Specifications Met: ASME B16.10, ASTM A126 Class B, AWWA C509, FM Approved, MSS-SP-70, UL Listed

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 9" | 22 3/4" | 9" | 00000000 | 000000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: PTFE Plastic

- Specifications Met: American Petroleum Institute Standard 603, ASME B16.34

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 2,150 | 150 | 275 psi @ 100° F | 150 psi @ 365° F | 0° to 375° | 9" | 25 15/16" | 9 13/16" | 00000000 | 000000000 |

- Valve Type: Gate

- For Use With: Oil, Air, Argon, Helium, Krypton, Neon, Xenon

- Packing Material: Graphite

O'all | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolts Included | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 4 | 3/4" | 9" | 7 1/2" | 8 | No | 685 | 125 | 10 psi @ 1000° F | -40° to 1000° | 5 1/4" | 15 5/8" | 6" | 0000000 | 0000000 |

Flanged Gradual On/Off Valves for Thick Liquids and Dry Materials

- Valve Type: Gate

- For Use With: Air, Argon, Deionized Water, Ethanol, Ethylene Glycol, Helium, Isopropyl Alcohol, Krypton, Methanol, Neon, Nitrogen, Salt Water, Soap Solutions, Water, Xenon

These valves have a sharp gate that slices through thick slurries, wastewater, dry bulk solids, and other materials that would clog other gradual on/off valves. They bolt to flanges and gradually open and close to prevent system damage from suddenly starting and stopping flow. The wheel handle opens and closes the valve with multiple turns, providing controlled, shock-resistant flow. The rising stem lifts as the valve opens and lowers as the valve closes to provide a visual indication of whether flow is on or off. The stem is isolated from the process media for a long service life.

For technical drawings and 3-D models, click on a part number.

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | Bolt Hole Dia. | Bolt Circle Dia. | No. of Bolt Holes | Bolts Included | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | |

Ductile Iron Body—316 Stainless Steel Gate | |||||||||||||

| 4 | 9" | 5/8" | 7 1/2" | 8 | No | 150 psi @ 248° F | -22° to 248° | 2 1/4" | 29 7/16" | 6 3/4" | Rising | 0000000 | 000000000 |

Plastic Socket-Connect Gradual On/Off Valves

Female ×

Socket-Connect Female

- Valve Type: Gate

- For Use With: Water

For a lightweight and economical alternative to metal valves, these are made of plastic. Insert unthreaded pipe into the socket ends and bond with PVC primer and cement to create a permanent, leak-tight connection. Valves gradually open and close to prevent system damage from suddenly starting and stopping flow. Pull the handle to open the valve. All valves have a rising stem that lifts as the valve opens and lowers as the valve closes to provide a visual indication of whether flow is on or off.

304 stainless steel gates are more durable than glass-filled polypropylene gates.

For technical drawings and 3-D models, click on a part number.

O'all | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Color | Each | |

Socket Connect Female × Socket Connect Female | |||||||||

PVC Plastic Body—304 Stainless Steel Gate | |||||||||

| 4 × 4 | 20 psi @ 120° F | 35° to 120° | 5 3/16" | 18" | 6 11/16" | Rising | White | 0000000 | 000000 |

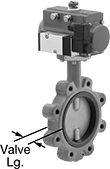

Flanged Air-Driven On/Off Valves

- Valve Type: Butterfly

- For Use With: Water, Air, Argon, Helium, Neon, Steam, Xenon, Krypton, Drinking Water

- Seal Material : EPDM Rubber

- Specifications Met: API 609, NSF/ANSI 61

To automatically start and stop flow faster than motor-driven valves, these operate on compressed air. You must control the air to the actuator using either the included electric pilot valve or a manual on/off valve (not included). Valves don’t require a minimum pressure drop between the inlet and outlet for operation.

The actuator is directly mounted to the valve body to minimize movement and reduce wear. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. The manual override allows you to operate the valve during power outages. Valves meet NSF/ANSI 61 for use with drinking water.

All valves are lug style; their hole pattern matches ANSI flanges of the same pipe size. They can be sandwiched between two flanges, or bolt them directly to a single flange for servicing one end of the pipeline without depressurizing the other side.

Single-acting actuators only require air pressure to open the valve; they automatically spring closed when the air turns off. These valves are normally closed unless actuated. Double-acting actuators require air pressure to open and close the valve. Once actuated, these valves remain actuated until air pressure is applied, so they do not have a valve starting position.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Bolts | Air | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Connection | Pressure Range, psi | Each | |

Ductile Iron Body with Screw Terminals | |||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed)—120V AC | |||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | -30° to 250° | 2 1/16" | 17 15/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 0000000 |

Double Acting: Air-to-Open, Air-to-Close—120V AC | |||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | -30° to 250° | 2 1/16" | 17" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

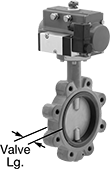

Air-Driven On/Off Valves for Fuel

- Valve Type: Butterfly

- For Use With: Oil, Diesel Fuel, Ethylene Glycol, Kerosene, Butane, Fuel Oil, Gasoline, Natural Gas, Propane

- Seal Material : Viton® Fluoroelastomer Rubber

- Specifications Met: API 609, MSS-SP-67

Use these valves to safely transfer fuel and oil. They operate on compressed air to automatically start and stop flow faster than motor-driven valves. You must control the air to the actuator using either the included electric pilot valve or a manual on/off valve (not included). These valves don’t require a minimum pressure drop between the inlet and outlet for operation.

The actuator is directly mounted to the valve body to minimize movement and reduce wear. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. The manual override allows you to operate the valve during power outages.

All valves are lug style; their hole pattern matches ANSI flanges of the same pipe size. They can be sandwiched between two flanges, or bolt them directly to a single flange for servicing one end of the pipeline without depressurizing the other side.

Single-acting actuators only require air pressure to open the valve; they automatically spring closed when the air turns off. These valves are normally closed unless actuated. Double-acting actuators require air pressure to open and close the valve. Once actuated, these valves remain actuated until air pressure is applied, so they do not have a valve starting position.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Bolts | Air | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Connection | Pressure Range, psi | Each | |

Ductile Iron Body with Screw Terminals | |||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed)—120V AC | |||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | 10° to 350° | 2 1/16" | 18 9/16" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000000 |

Double Acting: Air-to-Open, Air-to-Close—120V AC | |||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | 10° to 350° | 2 1/16" | 17 1/2" | 1/4 NPT Female | 40 to 115 | 0000000 | 000000 |

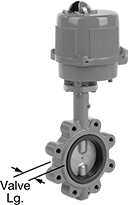

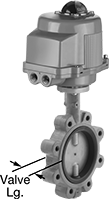

Flanged Motor-Driven On/Off Valves

- Valve Type: Butterfly

- For Use With: Water, Oil, Air, Natural Gas, Drinking Water, Propane, Butane, Argon, Helium, Neon, Steam, Xenon, Krypton

- Seal Material: EPDM Rubber

- Specifications Met: API 609, NSF/ANSI 61

Automatically start and stop flow in flanged pipelines with these valves that operate on electricity. All are fail in place; upon loss of power, the valve will remain in its current position.

The actuator is directly mounted to the valve body to minimize movement and reduce wear. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. Two single pole, double throw (SPDT) auxiliary switches allow you to connect these valves to temperature-monitoring equipment, programmable logic controllers, or conveyor sirens. The internal heater automatically turns on when the valve is actuated to prevent motor damage caused by condensation buildup. Valves meet NSF/ANSI Standard 61 for use with drinking water.

All valves are lug style; their hole pattern matches ANSI flanges of the same pipe size. They can be sandwiched between two flanges, or bolt them directly to a single flange for servicing one end of the pipeline without depressurizing the other side.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Bolts | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Port Type | Pipe Size | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Manual Override | Actuation Time, sec. | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Ductile Iron Body with Screw Terminals | ||||||||||||||||

Fail in Place—24V AC/DC | ||||||||||||||||

| Full | 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | Yes | 9 | -30° to 250° | 2 1/16" | 21 5/8" | 0000000 | 000000000 |

Fail in Place—120V AC | ||||||||||||||||

| Full | 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | Yes | 9 | -30° to 250° | 2 1/16" | 21 5/8" | 0000000 | 00000000 |

Motor-Driven On/Off Valves for Fuel

- Valve Type: Butterfly

- For Use With: Oil, Natural Gas, Propane, Butane, Diesel Fuel, Ethylene Glycol, Fuel Oil, Gasoline, Kerosene

- Seal Material: Viton® Fluoroelastomer Rubber

- Specifications Met: API 609, MSS-SP-67

Use these valves to safely transfer fuel and oil. They operate on electricity to automatically start and stop flow. All are fail in place; upon loss of power, the valve will remain in its current position.

The actuator is directly mounted to the valve body to minimize movement and reduce wear. A visual flow indicator on the top of the actuator shows whether the valve is open or closed. Two single pole, double throw (SPDT) auxiliary switches allow you to connect these valves to temperature-monitoring equipment, programmable logic controllers, or conveyor sirens. The internal heater automatically turns on when the valve is actuated to prevent motor damage caused by condensation buildup. The manual override allows you to operate the valve during power outages.

All valves are lug style; their hole pattern matches ANSI flanges of the same pipe size. They can be sandwiched between two flanges, or bolt them directly to a single flange for servicing one end of the pipeline without depressurizing the other side.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Bolts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | No. of Holes | Hole Size | Included | Circle Dia. | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Actuation Time, sec. | Temp. Range, °F | Valve Lg. | O'all Ht. | Each | |

Ductile Iron Body with Screw Terminals | ||||||||||||||

Fail in Place—24V AC/24V DC | ||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | 9 | 10° to 350° | 2 1/16" | 21 5/8" | 0000000 | 000000000 |

Fail in Place—120V AC | ||||||||||||||

| 4 | 9" | 8 | 5/8" | No | 7 1/2" | 605 | 250 psi @ 100° F | Zero Pressure Drop | 9 | 10° to 350° | 2 1/16" | 21 5/8" | 0000000 | 00000000 |