How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Gradual On/Off Valves

More

About On/Off Valves

More

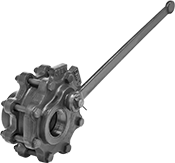

Compact Flanged On/Off Valves

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Steam, Water, Xenon

- Seal Material: PTFE Plastic

- Specifications Met: ASME B16.34, ASME B16.5, ASME B31.1

Also known as wafer ball valves, these combine the slim body of a butterfly valve with the high flow rates of a flanged ball valve. Bolt these valves to ANSI flanges—they meet ASME standards for dimensions, material, and pressure-temperature rating. They are full port, so they do not restrict flow.

316 stainless steel valves are more corrosion resistant than steel valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Bolts | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Thread Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Actuator Mounting Hole Thread Size | Each | |

Steel Body | |||||||||||||||

Flanged × Flanged | |||||||||||||||

| 1 | 150 | 4 1/4" | 3 1/8" | 4 | 1/2"-13 | No | 74.6 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 1 13/16" | M5 | 00000000 | 0000000 |

| 1 1/2 | 150 | 5" | 3 7/8" | 4 | 1/2"-13 | No | 201.3 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 2 1/2" | M6 | 00000000 | 000000 |

| 2 | 150 | 6" | 4 3/4" | 4 | 5/8"-11 | No | 348.6 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 3 1/4" | M6 | 00000000 | 000000 |

| 2 1/2 | 150 | 7" | 5 1/2" | 4 | 5/8"-11 | No | 631.4 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 4 1/16" | M8 | 00000000 | 000000 |

| 3 | 150 | 7 1/2" | 6" | 4 | 5/8"-11 | No | 1,009.5 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 4 13/16" | M8 | 00000000 | 000000 |

| 4 | 150 | 9" | 7 1/2" | 8 | 5/8"-11 | No | 1,577.3 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 6" | M10 | 00000000 | 000000 |

| 6 | 150 | 11" | 9 1/2" | 8 | 3/4"-10 | No | 4,247.5 | 285 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 9 1/8" | M12 | 00000000 | 00000000 |

316 Stainless Steel Body | |||||||||||||||

Flanged × Flanged | |||||||||||||||

| 1/2 | 150 | 3 1/2" | 2 3/8" | 4 | 1/2"-13 | No | 22.2 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 1 3/8" | M5 | 00000000 | 000000 |

| 3/4 | 150 | 3 7/8" | 2 3/4" | 4 | 1/2"-13 | No | 40.5 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 1 9/16" | M5 | 00000000 | 000000 |

| 1 | 150 | 4 5/16" | 3 1/8" | 4 | 1/2"-13 | No | 74.6 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 1 13/16" | M5 | 0000000 | 000000 |

| 1 1/4 | 150 | 4 5/8" | 3 1/2" | 4 | 1/2"-13 | No | 120.1 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 2 1/8" | M5 | 00000000 | 000000 |

| 1 1/2 | 150 | 5 1/8" | 3 7/8" | 4 | 1/2"-13 | No | 201.3 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 2 1/2" | M6 | 0000000 | 000000 |

| 2 | 150 | 6" | 4 3/4" | 4 | 5/8"-11 | No | 348.6 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 3 1/4" | M6 | 0000000 | 000000 |

| 2 1/2 | 150 | 7 5/16" | 5 1/2" | 4 | 5/8"-11 | No | 631.4 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 4 1/16" | M8 | 0000000 | 000000 |

| 3 | 150 | 7 1/2" | 6" | 4 | 5/8"-11 | No | 1,009.5 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 4 13/16" | M8 | 0000000 | 00000000 |

| 4 | 150 | 9" | 7 1/2" | 8 | 5/8"-11 | No | 1,577.3 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 6" | M10 | 0000000 | 00000000 |

| 6 | 150 | 11" | 9 1/2" | 8 | 3/4"-10 | No | 4,247.5 | 275 psi @ 100° F | 50 psi @ 295° F | 0° to 365° | 28 | 9 1/8" | M12 | 00000000 | 00000000 |

On/Off Valves with Press-Connect Fittings

Crimp these valves to metal tubing for a permanent, leak-tight connection that doesn’t require heat or soldering. All are full port, so they do not restrict flow. Choose a crimping tool based on your valve's compatibility: Viega ProPress or Viega MegaPress.

Bronze valves resist corrosion better than brass and zinc-nickel-plated steel valves. Zinc-nickel-plated steel valves are stronger and more durable than brass and bronze valves, so they last longer. 316 stainless steel valves have excellent corrosion resistance.

Valves with EPDM rubber seals are often found in water-processing lines, fire sprinklers, and heating and cooling systems. Compared to valves with Buna-N rubber seals, these valves better handle soapy solutions and temperature fluctuations. Valves with Buna-N rubber seals stand up to water, oil, fuel, and lubricants, so they work well in fuel gas systems and air lines. They meet ANSI standards for fuel gas systems and comply with the International Fuel Gas Code.

Fix lockable lever handles in place using a padlock (not included).

Valves that meet ASME B31 code requirements adhere to standards for pressure piping systems.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Air, Butane, Diesel Fuel, Natural Gas, Oil, Propane

- Pipe: Use Schedule 10, 40 steel

- Seal Material: Buna-N Rubber

- Specifications Met: ANSI LC4/CSA 6.32, ASME B31.1, ASME B31.3, ASME B31.9, International Fuel Gas Code

- Compatible With: Viega MegaPress

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Press Connect × Press Connect | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 125 psi @ 100° F | -40° to 180° | 5 3/16" | 1/4" | 0000000 | 000000 |

| 3/4 | 33 | 125 psi @ 100° F | -40° to 180° | 5 9/16" | 1/4" | 0000000 | 000000 |

| 1 | 46 | 125 psi @ 100° F | -40° to 180° | 6 1/4" | 1/4" | 0000000 | 000000 |

| 1 1/4 | 93 | 125 psi @ 100° F | -40° to 180° | 7 1/2" | 1/4" | 0000000 | 000000 |

| 1 1/2 | 124 | 125 psi @ 100° F | -40° to 180° | 7 15/16" | 1/4" | 0000000 | 000000 |

| 2 | 246 | 125 psi @ 100° F | -40° to 180° | 8 11/16" | 1/4" | 0000000 | 000000 |

- Valve Type: Ball

- For Use With: Air, Water

- Pipe: Use Schedule 10, 40 steel

- Seal Material: EPDM Rubber

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Compatible With: Viega MegaPress

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Press Connect × Press Connect | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 250 psi @ 100° F | 0° to 250° | 5 3/16" | 1/4" | 0000000 | 000000 |

| 3/4 | 33 | 250 psi @ 100° F | 0° to 250° | 5 9/16" | 1/4" | 0000000 | 000000 |

| 1 | 46 | 250 psi @ 100° F | 0° to 250° | 6 5/16" | 1/4" | 0000000 | 000000 |

| 1 1/4 | 93 | 250 psi @ 100° F | 0° to 250° | 7 9/16" | 1/4" | 0000000 | 000000 |

| 1 1/2 | 124 | 250 psi @ 100° F | 0° to 250° | 8" | 1/4" | 0000000 | 000000 |

| 2 | 246 | 250 psi @ 100° F | 0° to 250° | 8 11/16" | 1/4" | 0000000 | 000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Water

- Pipe: Use Schedule 10, 40 stainless steel

- Seal Material: Fluoroelastomer Rubber

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Compatible With: Viega MegaPress

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Press Connect × Press Connect | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 250 psi @ 100° F | 15° to 250° | 5 5/16" | 1/4" | 0000000 | 0000000 |

| 3/4 | 33 | 250 psi @ 100° F | 15° to 250° | 5 5/8" | 1/4" | 0000000 | 000000 |

| 1 | 46 | 250 psi @ 100° F | 15° to 250° | 6 3/8" | 1/4" | 0000000 | 000000 |

| 1 1/4 | 93 | 250 psi @ 100° F | 15° to 250° | 7 5/8" | 1/4" | 0000000 | 000000 |

| 1 1/2 | 124 | 250 psi @ 100° F | 15° to 250° | 8 1/16" | 1/4" | 0000000 | 000000 |

| 2 | 246 | 250 psi @ 100° F | 15° to 250° | 8 3/4" | 1/4" | 0000000 | 000000 |

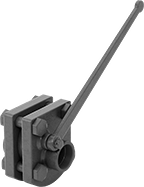

Threaded Gradual On/Off Valves for Boiler Blow-Off

Prevent boiler scale deposits and sediment buildup with these valves that meet ASME standards for boiler drainage applications. Also known as gate valves, they gradually open and close to prevent system damage from suddenly starting or stopping flow.

Valves with a wheel handle open and close with multiple turns, providing more controlled, shock-resistant flow than valves with a lever handle. Valves with a lever handle open and close faster than valves with a wheel handle.

Valves with a nonrising stem fit well in low-clearance places since the handle doesn’t move up when the valve opens.

Cast iron valves absorb vibration, reducing noise from your industrial boiler. Steel valves resist corroding from the dirt and particles that come out of industrial boilers better than cast iron valves.

Use repair kits to replace worn-out seals.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Water

- Packing Material: EPDM Rubber

- Specifications Met: ASME B16.34, ASME B16.5, ASME B31.1, ASME BPVC.I

Valves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

O'all | Repair Kits | |||||||||

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | Each | ||

NPT Female | ||||||||||

| 1 1/4 | 60 | 250 psi @ 350° F | 35° to 350° | 3 5/8" | 13" | 9" | 0000000 | 000000000 | 00000000 | 0000000 |

| 1 1/2 | 108 | 250 psi @ 350° F | 35° to 350° | 4 1/2" | 13" | 9 1/2" | 0000000 | 00000000 | 00000000 | 000000 |

| 2 | 132 | 250 psi @ 350° F | 35° to 350° | 4 5/8" | 14" | 9 11/16" | 0000000 | 00000000 | 00000000 | 000000 |

- Valve Type: Gate

- For Use With: Water

- Packing Material: EPDM Rubber

- Specifications Met: ASME B16.34, ASME B16.5, ASME B31.1, ASME BPVC.I

Valves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

O'all | Repair Kits | |||||||||

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | Each | ||

NPT Female | ||||||||||

| 1 | 40 | 250 psi @ 350° F | 35° to 350° | 3 5/8" | 14 1/4" | 4 7/16" | 0000000 | 0000000 | 00000000 | 0000000 |

| 1 1/4 | 60 | 250 psi @ 350° F | 35° to 350° | 3 5/8" | 13 1/16" | 4 3/4" | 0000000 | 000000 | 00000000 | 000000 |

| 1 1/2 | 108 | 250 psi @ 350° F | 35° to 350° | 4 1/2" | 20 3/8" | 5 13/16" | 0000000 | 000000 | 00000000 | 000000 |

| 2 | 132 | 250 psi @ 350° F | 35° to 350° | 4 5/8" | 21 5/16" | 6 1/16" | 0000000 | 00000000 | 00000000 | 000000 |

- Valve Type: Gate

- For Use With: Water

- Packing Material: Graphite/TFE Plastic Blend

- Specifications Met: ASME B16.34, ASME B16.5, ASME B31.1, ASME BPVC.I

Valves | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

O'all | Repair Kits | |||||||||

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | Each | ||

NPT Female | ||||||||||

| 1 1/4 | 60 | 490 psi @ 750° F | 35° to 750° | 5 1/4" | 13 1/8" | 5 1/4" | 00000000 | 000000000 | 00000000 | 0000000 |

| 1 1/2 | 108 | 490 psi @ 750° F | 35° to 750° | 6" | 17 11/16" | 6" | 00000000 | 00000000 | 00000000 | 000000 |

| 2 | 132 | 490 psi @ 750° F | 35° to 750° | 6 1/4" | 23 9/16" | 6 1/4" | 00000000 | 00000000 | 00000000 | 000000 |

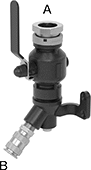

Aluminum Quick-Connect Pipe Fittings for Compressed Air

Twist these fittings onto aluminum pipe for quick, sealed connections—no threading, soldering, or welding necessary. Use them to build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe fittings, they’re part of a quick-connect system that’s compatible with pipe from Unipipe, Transair, and Infinity.

Finger tighten the collar on the end of these fittings, then use a wrench for the final quarter turn. The inside of these fittings has a compression ring and O-ring to seal against the pipe. They’re easy to take apart as needed to modify your setup.

Choose fittings with a blue or gray collar for easy identification. Fittings with a blue collar are often used for compressed air systems. Fittings with a gray collar are often used for vacuum systems.

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Fittings with outlets supply air where it’s needed using ¼ universal quick-disconnect couplings. They're compatible with Industrial, ARO, or European plugs. Connect them to a saddle tap tee anywhere along your pipeline. Each outlet also has a ¼ NPT port for draining the line or attaching a pressure gauge. Connect to strut channel with a strut-mount adapter (sold separately). Do not use them in vacuum applications.

Adapters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Valve Handles | Strut Channel Adapters | ||||||||||||

| For Pipe OD (A) | Coupling Size (B) | Material | Color | Max. Pressure | Mounting Fasteners Included | Dia., mm | No. of | Includes | Each | Each | Each | |||

Blue Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Gray Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Fittings with outlets supply air where it’s needed using ¼ universal quick-disconnect couplings. They're compatible with Industrial, ARO, or European plugs. Connect them to a saddle tap tee anywhere along your pipeline. Each outlet also has a ¼ NPT port for draining the line or attaching a pressure gauge. Connect to strut channel with a strut-mount adapter (sold separately). Do not use them in vacuum applications.

Adapters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Valve Handles | Strut Channel Adapters | ||||||||||||

| For Pipe OD (A) | Coupling Size (B) | Material | Color | Max. Pressure | Mounting Fasteners Included | Dia., mm | No. of | Includes | Each | Each | Each | |||

Blue Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Gray Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Use measuring tools to mark your pipe’s proper insertion depth so you know if it’s inserted far enough into the fitting.

| Max. Dp. Measured, mm | Lg., mm | Wd., mm | Material | Each | |

| 160 | 224 | 39 | Plastic | 0000000 | 000000 |