How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Gradual On/Off Valves

More

About On/Off Valves

More

On/Off Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Ball

- For Use With: Acetone, Air, Ammonia, Carbon Dioxide, Diesel Fuel, Gasoline, Kerosene

- Ball Material: Monel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Specifications Met: ASME B16.34, ASME B31.3

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. These valves have a PTFE seal and a corrosion-resistant Monel ball and body that can stand up to aggressive and corrosive chemicals such as acetone. All are standard port, so they slightly restrict flow. A red handle makes them easy to identify.

For technical drawings and 3-D models, click on a part number.

Threaded Gradual On/Off Valves for Cryogenic Liquid

- Valve Type: Gate

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Natural Gas, Liquid Methane, Liquid Nitrogen, Liquid Oxygen

- Packing Material: PTFE Plastic

- Specifications Met: ASME B31.3, CGA G-4.1, MSS-SP-80

Built to handle the extreme cold of liquid gases, these bronze valves are ideal for liquid carbon dioxide carbonation systems, liquid nitrogen coolant systems, and other cryogenic applications. They’ll also work with liquified natural gas and liquid oxygen. They’re cleaned and bagged to meet CGA G-4.1 for oxygen service. Also known as gate valves, they open and close gradually with multiple turns of the wheel handle to prevent sudden starts and stops.

The handle raises as these valves open and lowers as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. They have a threaded union stem housing, so you can separate the stem from the housing while the valve is inline. That means you can complete maintenance tasks, such as packing the stem, without taking apart your whole setup.

For technical drawings and 3-D models, click on a part number.

O'all | Stem | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Type | Housing Connection Style | Each | |

NPT Female | ||||||||||

Wheel Handle—Bronze Body and Brass Gate | ||||||||||

| 1/2 | 19.8 | 600 psi @ 72° F | -320° to 150° | 2 5/16" | 10 3/16" | 2 5/16" | Rising | Threaded Union | 0000000 | 0000000 |

| 3/4 | 36 | 600 psi @ 72° F | -320° to 150° | 2 1/2" | 11 5/16" | 2 1/2" | Rising | Threaded Union | 0000000 | 000000 |

| 1 | 60 | 600 psi @ 72° F | -320° to 150° | 2 7/8" | 13 1/2" | 2 7/8" | Rising | Threaded Union | 0000000 | 000000 |

| 1 1/2 | 152 | 600 psi @ 72° F | -320° to 150° | 3 7/16" | 18 3/8" | 3 7/16" | Rising | Threaded Union | 0000000 | 00000000 |

| 2 | 245 | 600 psi @ 72° F | -320° to 150° | 3 13/16" | 21 5/16" | 3 13/16" | Rising | Threaded Union | 0000000 | 00000000 |

Aluminum Quick-Connect Pipe Fittings for Compressed Air

Twist these fittings onto aluminum pipe for quick, sealed connections—no threading, soldering, or welding necessary. Use them to build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe fittings, they’re part of a quick-connect system that’s compatible with pipe from Unipipe, Transair, and Infinity.

Finger tighten the collar on the end of these fittings, then use a wrench for the final quarter turn. The inside of these fittings has a compression ring and O-ring to seal against the pipe. They’re easy to take apart as needed to modify your setup.

Choose fittings with a blue or gray collar for easy identification. Fittings with a blue collar are often used for compressed air systems. Fittings with a gray collar are often used for vacuum systems.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

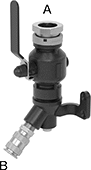

Fittings with outlets supply air where it’s needed using ¼ universal quick-disconnect couplings. They're compatible with Industrial, ARO, or European plugs. Connect them to a saddle tap tee anywhere along your pipeline. Each outlet also has a ¼ NPT port for draining the line or attaching a pressure gauge. Connect to strut channel with a strut-mount adapter (sold separately). Do not use them in vacuum applications.

Adapters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Valve Handles | Strut Channel Adapters | ||||||||||||

| For Pipe OD (A) | Coupling Size (B) | Material | Color | Max. Pressure | Mounting Fasteners Included | Dia., mm | No. of | Includes | Each | Each | Each | |||

Blue Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Gray Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Fittings with outlets supply air where it’s needed using ¼ universal quick-disconnect couplings. They're compatible with Industrial, ARO, or European plugs. Connect them to a saddle tap tee anywhere along your pipeline. Each outlet also has a ¼ NPT port for draining the line or attaching a pressure gauge. Connect to strut channel with a strut-mount adapter (sold separately). Do not use them in vacuum applications.

Adapters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Valve Handles | Strut Channel Adapters | ||||||||||||

| For Pipe OD (A) | Coupling Size (B) | Material | Color | Max. Pressure | Mounting Fasteners Included | Dia., mm | No. of | Includes | Each | Each | Each | |||

Blue Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 000000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Gray Collar | ||||||||||||||

| 3/4" (20 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 1" (25 mm) | 1/4 | Epoxy-Coated 6061 Aluminum | Black | 230 psi @ 72° F | No | 6 | 4 | Valve | 00000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

Use measuring tools to mark your pipe’s proper insertion depth so you know if it’s inserted far enough into the fitting.

| Max. Dp. Measured, mm | Lg., mm | Wd., mm | Material | Each | |

| 160 | 224 | 39 | Plastic | 0000000 | 000000 |