How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Gradual On/Off Valves

More

About On/Off Valves

More

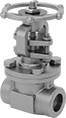

Threaded Gradual On/Off Valves

Also known as gate valves, these valves gradually open and close to prevent system damage from suddenly starting and stopping flow.

Valves with a wheel handle open and close with multiple turns, providing more controlled, shock-resistant flow than valves with a pull handle.

Valves with a nonrising stem keep the stem in the same position whether they’re open or closed. They’re often used underground and in low-clearance locations.

316 stainless steel valves resist corrosion better than bronze, brass, and cast iron valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Gate

- For Use With: See Table

- Specifications Met: See Table

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Stem Housing Connection Style | End-to-End Lg. | Ht. | Lg. | For Use With | Specifications Met | Each | |

NPT Female | ||||||||||||

| 1/2 | 17.6 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 2 1/8" | 4 1/2" | 2 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 000000 |

| 3/4 | 32 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 2 5/16" | 4 7/8" | 2 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 00000 |

| 1 | 54 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 2 11/16" | 5 3/8" | 3 1/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 000000 |

| 1 1/4 | 97 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 2 15/16" | 6 5/16" | 3 1/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 000000 |

| 1 1/2 | 135 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 3 1/8" | 7 1/2" | 3 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 000000 |

| 2 | 230 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | Threaded | 3 11/16" | 8 3/8" | 3 15/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | ASTM A351 | 0000000 | 000000 |

High-Pressure Threaded Gradual On/Off Valves

Designed for use in refineries and other demanding environments, these valves have a durable body that can withstand nearly twice the pressure of other gradual on/off valves. Also known as gate valves, they gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow.

These valves have a rising stem that lifts the handle as the valve opens and lowers as the valve closes. At a glance, you can see if flow is open or closed. The stem is isolated from what's flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. Their flanged stem housing, also known as a bolted bonnet, bolts in place to make them easy to take apart for maintenance and repairs. However, the flanged stem housing makes these valves heavier and larger than valves with threaded or welded stem housings.

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

316 stainless steel valves have excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: Graphite

- Specifications Met: American Petroleum Institute Standard 602, ASTM A105N

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | |

NPT Female | ||||||||||

Full Port | ||||||||||

| 1/4 | Not Rated | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 3 1/8" | 6 5/8" | 3 7/16" | Rising | 0000000 | 000000 |

| 3/8 | 9 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 3 1/8" | 6 5/8" | 3 7/16" | Rising | 0000000 | 00000 |

| 1/2 | 20 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 3 9/16" | 7" | 3 7/16" | Rising | 0000000 | 000000 |

| 3/4 | 33 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 4 5/16" | 8 11/16" | 3 13/16" | Rising | 0000000 | 000000 |

| 1 | 60 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 5" | 9 3/4" | 5 7/16" | Rising | 0000000 | 000000 |

| 1 1/4 | 92 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 5 15/16" | 11 5/16" | 5 7/16" | Rising | 0000000 | 000000 |

| 1 1/2 | 142 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 7 1/16" | 12 15/16" | 5 7/16" | Rising | 0000000 | 000000 |

| 2 | 257 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 6" | 15 3/4" | 6 3/4" | Rising | 0000000 | 000000 |

Standard Port | ||||||||||

| 1/2 | 9 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 3 1/8" | 6 5/8" | 3 7/16" | Rising | 0000000 | 00000 |

| 3/4 | 19 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 3 9/16" | 7" | 3 7/16" | Rising | 0000000 | 00000 |

| 1 | 32 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 4 5/16" | 8 11/16" | 3 13/16" | Rising | 0000000 | 00000 |

| 1 1/2 | 92 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 5 15/16" | 11 5/16" | 5 7/16" | Rising | 0000000 | 000000 |

| 2 | 144 | 1975 psi @ 100° F | 1100 psi @ 800° F | -20° to 800° | 5 1/4" | 12 3/16" | 5 7/16" | Rising | 0000000 | 000000 |

- Valve Type: Gate

- For Use With: Water, Air, Steam

- Packing Material: Graphite

- Specifications Met: American Petroleum Institute Standard 602, ASTM A182

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | |

NPT Female | ||||||||||

Standard Port | ||||||||||

| 1/2 | 7 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 3 1/8" | 6 3/4" | 3 1/8" | Rising | 00000000 | 0000000 |

| 3/4 | 14 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 3 9/16" | 6 7/8" | 3 9/16" | Rising | 00000000 | 000000 |

| 1 | 30 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 4 3/8" | 7 7/8" | 4 3/8" | Rising | 00000000 | 000000 |

| 1 1/4 | 85 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 4 11/16" | 10" | 4 11/16" | Rising | 00000000 | 000000 |

| 1 1/2 | 100 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 4 11/16" | 10 1/2" | 4 11/16" | Rising | 00000000 | 000000 |

| 2 | 160 | 1600 psi @ 100° F | 900 psi @ 800° F | -20° to 800° | 5 1/2" | 12 3/8" | 5 1/2" | Rising | 00000000 | 000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: Graphite

- Specifications Met: American Petroleum Institute Standard 602, ASTM A105N

O'all | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | |

NPT Female | ||||||||||

Standard Port | ||||||||||

| 3/4 | 18 | 3705 psi @ 100° F | 2060 psi @ 800° F | -20° to 800° | 4 5/16" | 8 7/16" | 3 13/16" | Rising | 0000000 | 0000000 |

| 1 | 30 | 3705 psi @ 100° F | 2060 psi @ 800° F | -20° to 800° | 5" | 9 3/4" | 5 7/16" | Rising | 0000000 | 000000 |

Flanged Gradual On/Off Valves

Nonrising Stem, and

Four Bolt Holes

Nonrising Stem, and

Eight Bolt Holes

Rising Stem, and

Four Bolt Holes

Rising Stem, and

Eight Bolt Holes

Bolt these valves to flanges. They gradually open and close to prevent system damage from suddenly starting and stopping flow.

Epoxy-coated cast iron valves are more corrosion resistant than plain cast iron or steel valves.

Wheel handles open and close with multiple turns, providing more controlled, shock-resistant flow than pull handles.

Nonrising stems stay in the same position whether the valve is open or closed. Valves with nonrising stems are often used underground and in other low-clearance locations.

Rising stems lift as the valve opens and lower as the valve closes to provide a visual indication of whether flow is on or off. The stem is isolated from the process media for a longer service life than valves with a nonrising stem.

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: Graphite

- Specifications Met: American Petroleum Institute Standard 600, ASTM A216 WCB

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 2 | 3/4" | 6" | 4 3/4" | 4 | 150 | 285 psi @ 100° F | 150 psi @ 365° F | -20° to 800° | 7" | 19 3/8" | 7" | 00000000 | 0000000 |

| 2 1/2 | 3/4" | 7" | 5 1/2" | 4 | 150 | 285 psi @ 100° F | 150 psi @ 365° F | -20° to 800° | 7 1/2" | 19 7/8" | 7 1/2" | 00000000 | 000000 |

| 3 | 3/4" | 7 1/2" | 6" | 4 | 150 | 285 psi @ 100° F | 150 psi @ 365° F | -20° to 800° | 8" | 24" | 8" | 00000000 | 000000 |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 150 | 285 psi @ 100° F | 150 psi @ 365° F | -20° to 800° | 9" | 27 1/2" | 9" | 00000000 | 00000000 |

- Valve Type: Gate

- For Use With: Water, Air

- Specifications Met: ASME B16.10, ASTM A126 Class B, AWWA C509, MSS-SP-70

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 3 | 3/4" | 7 1/2" | 6" | 4 | 125 | 200 psi @ 140° F | 35° to 140° | 8" | 14" | 8" | 00000000 | 0000000 |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 9" | 17" | 9" | 00000000 | 000000 |

| 6 | 7/8" | 11" | 9 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 10 1/2" | 22 5/16" | 10 1/2" | 00000000 | 00000000 |

- Valve Type: Gate

- For Use With: Water, Air

- Specifications Met: ASME B16.10, ASTM A126 Class B, AWWA C509, FM Approved, MSS-SP-70, UL Listed

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Bolt Hole Dia. | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Pressure Class | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

| 2 1/2 | 3/4" | 7" | 5 1/2" | 4 | 125 | 200 psi @ 140° F | 35° to 140° | 7 1/2" | 17 3/8" | 7 1/2" | 00000000 | 0000000 |

| 3 | 3/4" | 7 1/2" | 6" | 4 | 125 | 200 psi @ 140° F | 35° to 140° | 8" | 19 3/8" | 8" | 00000000 | 00000000 |

| 4 | 3/4" | 9" | 7 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 9" | 22 3/4" | 9" | 00000000 | 00000000 |

| 6 | 7/8" | 11" | 9 1/2" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 10 1/2" | 29 1/4" | 10 1/2" | 00000000 | 00000000 |

| 8 | 7/8" | 13 1/2" | 11 3/4" | 8 | 125 | 200 psi @ 140° F | 35° to 140° | 11 1/2" | 36" | 11 1/2" | 00000000 | 00000000 |

High-Pressure Socket-Connect Gradual On/Off Valves

With a forged steel body and bolted construction, these valves can withstand nearly 10 times the pressure of other socket-connect gradual valves. Insert unthreaded pipe into the socket ends and weld to create a permanent, leak-tight connection. Also known as gate valves, they gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow.

The handle raises as these valves open and lowers as they close to let you know if flow is on or off. The stem also raises when on so it doesn’t contact what’s flowing through your line. This gives these valves a longer lifespan than valves with a nonrising stem. Also known as bolted bonnets, their flanged stem housing bolts in place for easy disassembly during maintenance. However, the housing makes them larger and heavier than valves with a threaded or welded housing.

Full-port valves don’t restrict flow.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Gate

- For Use With: See Table

- Specifications Met: American Petroleum Institute Standard 602, ASTM A105N

O'all | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Coefficient (Cv) | Port Type | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | For Use With | Stem Type | Each | |

Socket Connect Female | ||||||||||||

| 1/4 | Not Rated | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 3 1/4" | 6 3/8" | 3 1/2" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 000000 |

| 3/8 | Not Rated | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 3 1/4" | 6 3/8" | 3 1/2" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 00000 |

| 1/2 | 5 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 3 3/16" | 6 1/2" | 3 7/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 00000 |

| 1/2 | 12 | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 3 1/2" | 7 3/8" | 3 1/2" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 00000000 | 000000 |

| 3/4 | 11 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 3 1/2" | 6 1/2" | 3 7/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 00000 |

| 3/4 | 23 | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 4 5/16" | 9 1/8" | 4 5/16" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 00000000 | 000000 |

| 1 | 25 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 4 3/8" | 8 1/4" | 4 1/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 00000 |

| 1 | 43 | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 5" | 10 1/2" | 5 3/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 00000000 | 000000 |

| 1 1/4 | 85 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 4 3/4" | 10 1/2" | 6 5/16" | Water, Air, Steam | Rising | 00000000 | 000000 |

| 1 1/2 | 77 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 5" | 10 5/8" | 6" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 000000 |

| 1 1/2 | 98 | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 5 1/4" | 13 1/2" | 5 3/8" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 00000000 | 000000 |

| 2 | 97 | Standard | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 5 3/8" | 11" | 6" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 0000000 | 000000 |

| 2 | 197 | Full | 1975 psi @ 100° F | 715 psi @ 800° F | -20° to 800° | 6" | 16 1/2" | 6 3/4" | Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam | Rising | 00000000 | 000000 |

Socket-Connect Gradual On/Off Valves

- Valve Type: Gate

- For Use With: Water, Oil, Air, Argon, Helium, Krypton, Neon, Xenon, Steam

- Packing Material: PTFE Plastic

- Specifications Met: ASTM A351

Insert unthreaded pipe into the socket ends and weld to create a permanent, leak-tight connection. Also known as gate valves, these valves gradually open and close with multiple turns of the wheel handle to prevent system damage from suddenly starting and stopping flow. Valves have a nonrising stem that stays in the same position whether the valve is open or closed. Body is 316 stainless steel for excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

O'all | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Stem Type | Each | |

Socket Connect Female | |||||||||

316 Stainless Steel Body and Gate | |||||||||

| 1/2 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 2 1/8" | 4 1/8" | 2 3/4" | Nonrising | 0000000 | 0000000 |

| 3/4 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 2 5/16" | 4 5/8" | 2 3/4" | Nonrising | 0000000 | 000000 |

| 1 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 2 11/16" | 5 3/8" | 3 1/8" | Nonrising | 0000000 | 000000 |

| 1 1/4 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 2 15/16" | 7 3/16" | 3 1/8" | Nonrising | 0000000 | 000000 |

| 1 1/2 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 3 1/8" | 7 7/16" | 3 15/16" | Nonrising | 0000000 | 000000 |

| 2 | 200 psi @ 350° F | 120 psi @ 350° F | 0° to 350° | 3 11/16" | 8 1/4" | 3 15/16" | Nonrising | 0000000 | 000000 |

Diverting Valves for Drinking Water

Exploded View |  Assembled View |

|

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: ASME B1.20.1, ASTM D1784, ASTM D2466, NSF/ANSI 61

To divert flow between ports in drinking water lines, use these valves that meet NSF/ANSI 61. Any port can be used as an inlet or an outlet. Turn the handle to direct flow from the inlet port to either outlet port at full capacity, direct flow to both outlet ports simultaneously at reduced capacity, or shut off flow completely. Valves have union fittings on all ends that disassemble for fast installation and removal from pipelines. In addition to threaded NPT female connections, they come with socket-connect (unthreaded) female fittings. All have a T-handle that resists accidental movement when snagged or bumped. Valves are full port, so they do not restrict flow.

For technical drawings and 3-D models, click on a part number.

Mounting Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flow Pattern | Max. Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Mounting Fasteners Included | No. of | Dia. | Each | |

Dark Gray PVC Plastic Body | ||||||||||

NPT Female × NPT Female × NPT Female | ||||||||||

| 1/2 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 5" | No | 4 | 7/32" | 00000000 | 000000 |

| 3/4 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 5 3/4" | No | 4 | 7/32" | 00000000 | 000000 |

| 1 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 6 9/16" | No | 4 | 7/32" | 00000000 | 000000 |

| 1 1/4 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 7 3/4" | No | 4 | 1/4" | 00000000 | 000000 |

| 1 1/2 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 8 5/16" | No | 4 | 1/4" | 00000000 | 000000 |

| 2 | T-Pattern | 230 psi @ 70° F | 40° to 140° | 29 | 10" | No | 4 | 1/4" | 00000000 | 000000 |

Color-Coded Quarter-Turn Shut-Off Valves for Hot and Cold Water

Quickly identify hot and cold water lines with these red or blue valves. The low-profile elbow shape and small handle are made to fit into tight spaces, such as plumbing outlet boxes (sold separately). Connect the NH/NST threads to a water hose on a washing machine or commercial plumbing fixture.

Valves with a barbed inlet are compatible with Viega PEX tubing; attach them to your line with a crimping tool and crimping ring (both sold separately).

Inlet—For

Hot Water

Inlet—For

Cold Water

90° Elbow | |||||||

|---|---|---|---|---|---|---|---|

| For Inlet Tube ID | Outlet Hose Size | Handle Material | Compatible With | Specifications Met | Choose a Handle Color | Each | |

Brass | |||||||

| 1/2" | 3/4 | Powder-Coated Aluminum | Viega PEX | ASTM F1807 | 0000000 | 000000 | |

| Wd. | Ht. | Dp. | Material | Mounting Fasteners Included | Number of Mounting Holes | Mounting Hole Dia. | Each | |

| 10 1/4" | 6 3/4" | 2 1/2" | PVC Plastic | No | 36 | 1/8" | 0000000 | 000000 |