Filter by

Blade Mount Type

For Use On

Blade Shape

Tooth Material

Body Material

Tooth Heat Treatment

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Manufacturer Model Number

Body Finish

Performance

Multipurpose Oscillating Tool Blades

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Lg. | Wd. | Dia. | Tooth | Body | Cut Type | Blade Shape | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Starlock Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 3/4" | 2 1/2" | — | High-Speed Steel | Carbon Steel | Plunge | Curved | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4" | 1 1/4" | — | High-Speed Steel | Carbon Steel | Plunge | Curved | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3 1/2" | 3/8" | — | High-Speed Steel | Carbon Steel | Plunge | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3 1/2" | 3/4" | — | High-Speed Steel | Carbon Steel | Plunge | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 3 3/4" | 2 1/2" | — | High-Speed Steel | Carbon Steel | Plunge | Curved | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 3 3/4" | 2 1/8" | — | High-Speed Steel | Carbon Steel | Plunge | Curved | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

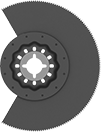

| F | — | — | 4" | High-Speed Steel | Carbon Steel | Flush, Straight | Half Round | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Life Multipurpose Oscillating Tool Blades

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Tooth | Body | Cut Type | Blade Shape | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Starlock Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/4" | Carbide-Tipped Steel | Black-Oxide Carbon Steel | Plunge | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | Carbide-Tipped Steel | Black-Oxide Carbon Steel | Plunge | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 1 3/8" | Carbide-Tipped Steel | Black-Oxide Steel | Plunge | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Blades for Cutting Wood

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Dia. | Tooth Heat Treatment | Tooth | Body | Cut Type | Blade Mount Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wood | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 1 1/4" | — | Not Hardened | High-Speed Steel | Carbon Steel | Flush, Plunge | Open | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wood and Wood with Nails | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 1 1/4" | — | Not Hardened | High-Speed Steel | Carbon Steel | Flush, Plunge | Open | 000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wood and Laminate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/4" | — | Not Hardened | High-Speed Steel | Carbon Steel | Plunge | Starlock | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wood, Laminate, and Wood with Nails | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 2 1/2" | — | Hardened | High-Speed Steel | Carbon Steel | Plunge | Starlock | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 1 3/4" | — | Hardened | High-Speed Steel | Carbon Steel | Plunge | Starlock | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 2 1/2" | — | Hardened | High-Speed Steel | Carbon Steel | Plunge | Open | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 1 3/4" | — | Hardened | High-Speed Steel | Carbon Steel | Plunge | Open | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Half-Round Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Wood and Wood with Nails | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 4" | Not Hardened | Titanium Nitride (TiN)-Coated Steel | Titanium Nitride (TiN)-Coated Steel | Flush | Open | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extra Long-Life Multipurpose Oscillating Tool Blades

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Tooth | Body | Cut Type | Blade Shape | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 1 3/8" | Carbide | Black-Oxide Steel | Flush, Plunge, Straight | Straight | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Blade Sets

Blade Mount Type | No. of Pieces | Includes | Cut Type | For Use On | Each | ||

|---|---|---|---|---|---|---|---|

| Starlock | 5 | 1 1/4" Lg. Steel Straight Blade with Carbide-Tipped Steel Teeth for Metal 1 1/4" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Wood 1 1/4" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Wood with Nails 1 1/4" Lg. Titanium Cobalt Curved Blade with Carbide-Tipped Steel Teeth for Wood with Nails, PVC, and Metal 2" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Drywall | Plunge | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 000000 | |

| Open | 5 | 1 1/4" Lg. Steel Straight Blade with Carbide-Tipped Steel Teeth for Metal 1 1/4" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Wood 1 1/4" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Wood with Nails 1 1/4" Lg. Titanium Cobalt Curved Blade with Carbide-Tipped Steel Teeth for Wood with Nails, PVC, and Metal 2" Lg. Carbon Steel Curved Blade with High-Speed Steel Teeth for Drywall | Plunge | Wood, Wood with Nails, Metal, Drywall, PVC | 0000000 | 00000 |

Extra Long-Life Oscillating Tool Blades for Cutting Thin Metal

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Tooth | Body | Cut Type | Blade Shape | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | 1 3/8" | Carbide | Black-Oxide Steel | Flush, Plunge, Straight | Straight | Metal | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Blades for Scraping Caulk and Paint

Oscillating Tool Blades for Cutting Soft Materials

Fast-Cut Oscillating Tool Blades for Cutting Wood

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Tooth | Body | Cut Type | For Use On | Blade Mount Type | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1 3/8" | High-Speed Steel | Carbon Steel | Straight | Drywall, PVC, Wood | Starlock | 10 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2 1/2" | High-Speed Steel | Carbon Steel | Straight | Drywall, PVC, Wood | Starlock | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Curved Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 3/4" | 2 1/2" | Black-Oxide High-Speed Steel | Black-Oxide Carbon Steel | Flush, Plunge, Straight | Drywall, PVC, Wood | Open | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/8" | Black-Oxide High-Speed Steel | Black-Oxide Carbon Steel | Flush, Plunge, Straight | Drywall, PVC, Wood | Open | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Long-Life Oscillating Tool Blades for Cutting Thin Metal

Oscillating Tool Blades for Cutting Thin Metal

Long-Life Oscillating Tool Blades for Cutting Wood

Oscillating Tool Blades for Grinding Grout

Cordless Oscillating Tools

|

Open Mount |

Starlock Mount |

Mfr. Model No. | Voltage, V DC | No-Load Oscillation Speed, oscillation/min | Oscillating Angle | Lg. | Wt., lb. | Batteries Included | Battery Charger Included | Blade Included | Blade Mount Type | Speed Control Switch Type | Features | Cannot Be Sold To | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

DeWalt | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DCS356B | 20 | 0 to 20,000 | 1.6° | 11 1/8" | 2.3 | No | No | Yes | Open | Lever | Speed Control, LED Light | — | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| DCS356D1 | 20 | 0 to 20,000 | 1.6° | 11 1/8" | 2.3 | Yes | Yes | Yes | Open | Lever | Speed Control, LED Light | — | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fein | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 129 36 62 09 0 | 18 | 10,000 to 19,500 | 2° | 11 1/4" | 2.4 | No | No | Yes | Starlock, StarlockMax, StarlockPlus | Dial | Speed Control, Cutting Resistance Detection, Touch-Free Blade Ejection, Automatic Shutoff | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 129 36 64 09 0 | 18 | 10,000 to 19,500 | 2° | 11 1/4" | 2.4 | Yes | Yes | Yes | Starlock, StarlockMax, StarlockPlus | Dial | Speed Control, Cutting Resistance Detection, Touch-Free Blade Ejection, Automatic Shutoff | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Makita | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| XMT04ZB | 18 | 10,000 to 20,000 | 3.6° | 12" | 3.7 | No | No | No | Starlock, StarlockMax, StarlockPlus | Dial | Speed Control, Cutting Resistance Detection, Soft Start, LED Light | Outside United States | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Milwaukee | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2836-20 | 18 | 10,000 to 20,000 | 4.2° | 12 1/8" | 2.6 | No | No | Yes | Open | Dial | Speed Control, Soft Start, LED Light | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2836-21 | 18 | 10,000 to 20,000 | 4.2° | 12 1/8" | 2.6 | Yes | Yes | Yes | Open | Dial | Speed Control, Soft Start, LED Light | — | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Sanding Pad Kits

For Sheet Shape | Lg. | Wd. | For Use On | Abrasive Material | Blade Mount Type | Mount Type | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Rough and Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Triangle | 3 1/2" | 3 1/2" | Steel, Wood | Aluminum Oxide | Starlock | Hook and Loop | Backup Pad; Five each 80, 120-grit Sheets | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Square | 3" | 5" | Steel, Wood | Aluminum Oxide | Starlock | Hook and Loop | Backup Pad; Two each 80, 120-grit Sheets | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Sanding Plates

|

Style A |

|

Style B |

Starlock Mount |

Open Mount |

Style | Grit | Lg. | Wd. | For Use On | Abrasive Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Starlock Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 20 | 3 1/4" | 3 1/2" | Wood | Carbide | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 40 | 3 1/4" | 3 1/2" | Wood | Carbide | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 60 | 3 1/4" | 3 1/2" | Wood | Carbide | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 100 | 3 1/4" | 3 1/2" | Wood | Carbide | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Open Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 20 | 3 1/4" | 3 1/2" | Grout, Wood | Carbide | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 40 | 4" | 1 1/4" | Grout, Wood | Carbide | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric Oscillating Tools

Current @ Voltage | No-Load Oscillation Speed, oscillation/min | Oscillating Angle | Lg. | Wt., lb. | Blade Mount Type | Features | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

DeWalt DWE315K—Trigger | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 amp @ 120V AC | 0 to 22,000 | 3.2° | 17" | 3.1 | Open | Speed Control, LED Light | Adapter for Use With Oscillating Tool Accessories One Blade for Cutting Wood One Blade for Cutting Wood with Nails One Half Round Blade for Cutting Wood, Wood with Nails, and Metal 25 Sanding Sheets Sanding Pad Cloth Case Plastic case | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bosch GOP40-30B—Dial | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 amp @ 120V AC | 8,000 to 20,000 | 3° | 11" | 3.3 | Starlock, StarlockPlus | Speed Control, Cutting Resistance Detection, Touch-Free Blade Ejection, LED Light | One Half Round Blade for Cutting Wood, Wood with Nails, Drywall, PVC, and Metal One Blade for Plunge Cuts in Wood and Laminate One Blade for Plunge Cuts in Wood, Wood with Nails, Drywall, PVC, and Metal 25 Sanding Sheets Sanding Pad Cloth Case | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bosch GOP55-36C2—Dial | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.5 amp @ 120V AC | 8,000 to 20,000 | 3.6° | 11" | 3.5 | Starlock, StarlockMax, StarlockPlus | Speed Control, Cutting Resistance Detection, Touch-Free Blade Ejection | One Blade for Plunge Cuts in Steel Two Half Round Blades for Cutting Wood, Wood with Nails, Drywall, PVC, and Metal Two Blades for Cutting Wood, Wood with Nails, Drywall, PVC, and Metal Two Blades for Plunge Cuts in Wood and Laminate One Blade for Cutting Carpet, Cardboard, and Shingles One Blade for Removing Grout and Mortar One Blade for Removing Grout One Blade for Removing Sealant, Paint, and Glue Two Blades for Removing Sealant 25 Sanding Sheets Sanding Pad Plastic case | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oscillating Tool Backup Pads for Sanding

Oscillating Tool Blades for Cutting Drywall

|

Material | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Tooth | Body | Cut Type | For Use On | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Starlock Blade Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | Carbon Steel | Carbon Steel | Plunge | Drywall | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||