Filter by

Width

Shaft Diameter

Length

OD

Shaft Mount Type

DFARS Specialty Metals

Maximum Torque

Maximum Rubbing Speed @ Pressure

Performance

ID

Drive Direction

Bearing Construction

One-Way Clutches

Roller Engagement—Knurled Hub

Shaft | Hub | Clockwise Drive | Counterclockwise Drive | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Shaft Type | Max. Torque, ft·lbf | Max. Rotation Speed, rpm | OD | Overall Lg. | Material | Keyway Wd. × Keyway Dp. | Mount Type | Dia. | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Round | 0.83 | 5,000 | 15/16" | 31/32" | Steel | — | Set Screw | 5/8" | 9/32" | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Keyed | 1.25 | 5,000 | 1 3/16" | 1" | Steel | 3/32" × 3/64" | Set Screw | 9/16" | 3/8" | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Keyed | 4.16 | 2,000 | 1 1/2" | 1 9/32" | Steel | 1/8" × 1/16" | Set Screw | 7/8" | 1/2" | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roller Engagement—Keyed Hub

Shaft | Hub | Clockwise Drive | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Shaft Type | Max. Torque, ft·lbf | Max. Rotation Speed, rpm | OD | Overall Lg. | Material | Keyway Wd. × Keyway Dp. | Mount Type | Dia. | Lg. | Keyway Wd. × Keyway Dp. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Keyed | 5 | 1,800 | 1 5/8" | 1 15/16" | Steel | 1/16" × 1/32" | Slip Fit | 7/8" | 13/16" | 3/16" × 3/32" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Keyed | 14 | 1,800 | 2" | 2 1/8" | Steel | 3/32" × 3/64" | Slip Fit | 1 1/4" | 1" | 3/16" × 3/32" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Keyed | 14 | 1,800 | 2" | 2 1/8" | Steel | 1/8" × 1/16" | Slip Fit | 1 1/4" | 1" | 3/16" × 3/32" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | Keyed | 28 | 1,500 | 2 5/8" | 2 23/32" | Steel | 3/16" × 3/32" | Slip Fit | 1 3/8" | 1 5/16" | 3/16" × 3/32" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Keyed | 100 | 1,000 | 3 5/8" | 3 11/32" | Steel | 3/16" × 3/32" | Slip Fit | 2 1/4" | 1 1/2" | 3/8" × 3/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Keyed | 100 | 1,000 | 3 5/8" | 3 11/32" | Steel | 1/4" × 1/8" | Slip Fit | 2 1/4" | 1 1/2" | 3/8" × 3/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Keyed | 100 | 1,000 | 3 5/8" | 3 11/32" | Steel | 1/4" × 1/8" | Slip Fit | 2 1/4" | 1 1/2" | 3/8" × 3/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Keyed | 200 | 800 | 4 1/2" | 4 1/2" | Steel | 3/8" × 3/16" | Slip Fit | 3" | 2 1/16" | 3/8" × 3/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sprag Engagement—Keyed Hub

Max. Rotation Speed, rpm | Shaft | Hub | Clockwise Drive | Counterclockwise Drive | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Shaft Type | Max. Torque, ft·lbf | Inner-Race | Outer-Race | OD | Overall Lg. | Material | Keyway Wd. × Keyway Dp. | Mount Type | Dia. | Lg. | Keyway Wd. × Keyway Dp. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | Keyed | 110 | 1,950 | 900 | 2" | 2 3/4" | Steel | 3/16" × 3/32" | Set Screw | 1 1/4" | 1" | 3/16" × 3/32" | 0000000 | 000000000 | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Keyed | 300 | 1,950 | 750 | 2.88" | 3.19" | Steel | 3/16" × 3/32" | Set Screw | 1 3/8" | 1 5/16" | 3/16" × 3/32" | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Keyed | 450 | 1,650 | 600 | 3 1/4" | 3.56" | Steel | 1/4" × 1/8" | Set Screw | 1 3/4" | 1 7/16" | 1/4" × 1/8" | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Keyed | 675 | 1,250 | 350 | 3 3/4" | 3 1/2" | Steel | 5/16" × 5/32" | Set Screw | 2 1/4" | 1 7/16" | 5/16" × 5/32" | 0000000 | 00000000 | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

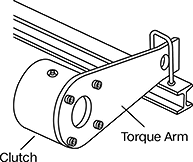

Sprag Engagement—Flush Hub

Clutches | Covers | Torque Arms | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Rotation Speed, rpm | Shaft | Clockwise or Counterclockwise Drive | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Shaft Dia. | For Shaft Type | Max. Torque, ft·lbf | Inner-Race | Outer-Race | OD | Overall Lg. | Material | Keyway Wd. × Keyway Dp. | Mount Type | Each | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Keyed | 300 | 2,800 | 850 | 3 1/2" | 2 3/4" | Steel | 3/16" × 3/32" | Slip Fit | 0000000 | 000000000 | 00000000 | 0000000 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Keyed | 1,175 | 2,500 | 800 | 4 1/4" | 3 1/2" | Steel | 1/4" × 1/8" | Slip Fit | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Keyed | 1,175 | 2,500 | 800 | 4 1/4" | 3 1/2" | Steel | 1/4" × 1/8" | Slip Fit | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | Keyed | 2,250 | 2,200 | 750 | 5 3/8" | 3 3/4" | Steel | 3/8" × 3/16" | Slip Fit | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | Keyed | 2,250 | 2,200 | 750 | 5 3/8" | 3 3/4" | Steel | 3/8" × 3/16" | Slip Fit | 0000000 | 00000000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One-Way Locking Needle-Roller Bearing Clutches

Radial Load Cap., lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Housing ID | Wd. | Ring Material | Dynamic | Static | Max. Rotation Speed, rpm | Max. Torque, ft·lbf | Lubrication | For Shaft Surface Smoothness, Ra, μin | Temp. Range, ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single-Row Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Springs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 9/32" | 1/4" | Steel | — | — | 34,000 | 0.2 | Required | 16 | -20 to 200 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 7/16" | 1/2" | Steel | — | — | 20,000 | 1.5 | Required | 16 | -20 to 200 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | 1/2" | Steel | — | — | 18,000 | 4 | Required | 16 | -20 to 200 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 1/2" | Steel | — | — | 17,000 | 6.5 | Required | 16 | -20 to 200 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 5/8" | Steel | — | — | 14,000 | 12 | Required | 16 | -20 to 200 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 5/8" | Steel | — | — | 12,000 | 17 | Required | 16 | -20 to 200 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 5/16" | 5/8" | Steel | — | — | 8,700 | 35 | Required | 16 | -20 to 200 | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

301 Stainless Steel Springs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 7/16" | 1/2" | Steel | — | — | 20,000 | 1.5 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | 1/2" | Steel | — | — | 18,000 | 4 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 1/2" | Steel | — | — | 17,000 | 6.5 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 5/8" | Steel | — | — | 14,000 | 12 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 5/8" | Steel | — | — | 12,000 | 17 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 5/16" | 5/8" | Steel | — | — | 8,700 | 35 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Springs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 10 mm | 12 mm | Steel | — | — | 23,000 | 1.3 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 12 mm | 12 mm | Steel | — | — | 17,000 | 2.3 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 14 mm | 12 mm | Steel | — | — | 14,000 | 3.9 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 18 mm | 16 mm | Steel | — | — | 11,000 | 9 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 mm | 20 mm | 16 mm | Steel | — | — | 9,500 | 12 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 22 mm | 16 mm | Steel | — | — | 8,500 | 15 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 mm | 24 mm | 16 mm | Steel | — | — | 7,500 | 17 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 26 mm | 16 mm | Steel | — | — | 7,000 | 21 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 32 mm | 20 mm | Steel | — | — | 5,500 | 45 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 37 mm | 20 mm | Steel | — | — | 4,500 | 65 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 mm | 42 mm | 20 mm | Steel | — | — | 3,900 | 85 | Required | 16 | 10 to 150 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triple-Row Bearing | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

301 Stainless Steel Springs | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | 7/8" | Steel | 1,350 | 1,100 | 18,000 | 4 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | 7/8" | Steel | 1,600 | 1,450 | 17,000 | 6.5 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 7/8" | 1" | Steel | 1,800 | 1,800 | 14,000 | 12 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | 1" | Steel | 2,000 | 2,200 | 12,000 | 17 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 5/16" | 1.063" | Steel | 3,450 | 3,950 | 8,700 | 35 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 14 mm | 20 mm | Steel | 940 | 680 | 21,000 | 3.2 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 16 mm | 20 mm | Steel | 1,050 | 850 | 19,000 | 4.2 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 18 mm | 26 mm | Steel | 1,400 | 1,300 | 19,000 | 10 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 mm | 22 mm | 26 mm | Steel | 1,450 | 1,600 | 14,000 | 16 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 mm | 26 mm | 26 mm | Steel | 1,800 | 2,100 | 11,000 | 24 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm | 32 mm | 30 mm | Steel | 2,500 | 2,900 | 8,700 | 50 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 mm | 37 mm | 30 mm | Steel | 2,550 | 3,350 | 7,300 | 70 | Required | 16 | -20 to 250 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

One-Way-Locking Sprockets

For Roller Chain | Keyway | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Trade No. | Std. | Pitch | No. of Teeth | OD | Bore Type | For Shaft Dia. | Wd. | Dp. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Single Strand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 15 | 2" | Finished | 1/2" | 1/8" | 9/16" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | ANSI | 3/8" | 25 | 3 3/16" | Finished | 5/8" | 3/16" | 23/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 12 | 2 3/16" | Finished | 1/2" | 1/8" | 9/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 15 | 2 5/8" | Finished | 1/2" | 1/8" | 9/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | ANSI | 1/2" | 20 | 3 7/16" | Finished | 3/4" | 3/16" | 27/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 12 | 2 11/16" | Finished | 1/2" | 1/8" | 9/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 15 | 3 5/16" | Finished | 3/4" | 3/16" | 27/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | ANSI | 5/8" | 20 | 4 5/16" | Finished | 1" | 1/4" | 1 3/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 12 | 3 1/4" | Finished | 5/8" | 3/16" | 23/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 14 | 3 3/4" | Finished | 3/4" | 3/16" | 27/32" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 60 | ANSI | 3/4" | 18 | 4 11/16" | Finished | 1 1/4" | 1/4" | 1 3/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electric One-Way Clutches

Friction Engagement

Clockwise Drive | Counterclockwise Drive | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia. | For Shaft Type | Max. Torque, in·lbf | Max. Rotation Speed, rpm | OD | Overall Lg. | Electric Clutch Type | Electrical Connection Type | Shaft Mount Type | Wire Lead Lg. | Voltage, V DC | Current, amp | Each | Current, amp | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | Round | 30 | 1,400 | 1 1/4" | 1 1/8" | Power On | Hardwire | Spring Pin | 15" | 24 | 0.14 | 0000000 | 0000000 | 0.24 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | Round | 30 | 1,400 | 1 1/4" | 1 1/8" | Power On | Hardwire | Spring Pin | 15" | 24 | 0.14 | 0000000 | 000000 | 0.24 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Round | 75 | 1,400 | 1 3/4" | 1 1/2" | Power On | Hardwire | Spring Pin | 18" | 24 | 0.14 | 0000000 | 000000 | 0.24 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Round | 75 | 1,400 | 1 3/4" | 1 1/2" | Power On | Hardwire | Spring Pin | 18" | 24 | 0.14 | 0000000 | 000000 | 0.24 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

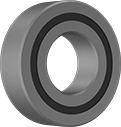

One-Way-Locking Ball Bearings

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Shaft Dia., mm | For Housing ID, mm | Wd., mm | ABEC Rating | Dynamic Radial Load Cap., lb. | Max. Rotation Speed, rpm | Max. Torque, ft·lbf | Min. | Max. | Inner Ring Type | Bearing Trade No. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Shielded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 22 | 9 | 1 | 720 | 15,000 | 1.5 | -40 | 170 | Standard | 608-2Z | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 10 | 1 | 1,150 | 10,000 | 6.5 | -40 | 170 | Standard | FZ 6201 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 11 | 1 | 1,160 | 9,400 | 15 | -40 | 170 | Standard | FZ 6202 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 12 | 1 | 1,270 | 8,200 | 23 | -40 | 170 | Standard | FZ 6203 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 14 | 1 | 1,540 | 6,800 | 64 | -40 | 170 | Standard | FZ 6204 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 15 | 1 | 1,620 | 5,600 | 70 | -40 | 170 | Standard | FZ 6205 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 16 | 1 | 1,730 | 4,000 | 165 | -40 | 170 | Standard | FZ 6206 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 17 | 1 | 1,830 | 3,600 | 240 | -40 | 170 | Standard | FZ 6207 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 22 | 1 | 2,010 | 3,000 | 305 | -40 | 170 | Standard | FZ 6208 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sealed | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 32 | 14 | 1 | 1,150 | 10,000 | 6.5 | -40 | 170 | Standard | FZ 6201 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 35 | 16 | 1 | 1,160 | 8,400 | 15 | -40 | 170 | Standard | FZ 6202 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 40 | 17 | 1 | 1,270 | 7,300 | 23 | -40 | 170 | Standard | FZ 6203 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 47 | 19 | 1 | 1,540 | 6,000 | 64 | -40 | 170 | Standard | FZ 6204 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 52 | 20 | 1 | 1,620 | 5,200 | 70 | -40 | 170 | Standard | FZ 6205 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 62 | 21 | 1 | 1,730 | 4,200 | 165 | -40 | 170 | Standard | FZ 6206 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 35 | 72 | 22 | 1 | 1,830 | 3,600 | 240 | -40 | 170 | Standard | FZ 6207 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 80 | 27 | 1 | 2,010 | 3,000 | 305 | -40 | 170 | Standard | FZ 6208 2RS | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Friction Brake and Clutch Friction Lining

7 1/2" × 7 1/2" | 15" × 15" | 30" × 30" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Max. Rubbing Speed @ Pressure | Max. Coeff. of Friction | Max. Temp., ° F | Max. Pressure, psi | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Molded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 000000 | 00000000 | 000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 5,000 fpm @ 500 psi | 0.55 | 550 | 500 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Friction Brake and Clutch Friction Lining

7 1/2" × 7 1/2" | 15" × 15" | 30" × 30" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Max. Rubbing Speed @ Pressure | Max. Coeff. of Friction | Max. Temp., ° F | Max. Pressure, psi | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Molded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 4,500 fpm @ 600 psi | 0.14 | 600 | 600 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Medium-Friction Brake and Clutch Friction Lining

7 1/2" × 7 1/2" | 15" × 15" | 30" × 30" | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Max. Rubbing Speed @ Pressure | Max. Coeff. of Friction | Max. Temp., ° F | Max. Pressure, psi | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Molded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 5,000 fpm @ 500 psi | 0.35 | 550 | 500 | 0000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Brake and Clutch Friction Lining

Thk. | Wd. | Max. Rubbing Speed @ Pressure | Max. Coeff. of Friction | Max. Temp., ° F | Max. Pressure, psi | 1 ft. Long | 2 ft. Long | 3 ft. Long | 4 ft. Long | 5 ft. Long | 6 ft. Long | 10 ft. Long | 15 ft. Long | 20 ft. Long | 25 ft. Long | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Woven | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 3/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 3/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 3/4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 3" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 2 1/2" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 4" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 6" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 8" | 5,000 fpm @ 200 psi | 0.51 | 500 | 200 | 00000000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | 00000000 | 00000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Metal-Free Brake and Clutch Friction Lining

Thk. | Wd. | Max. Rubbing Speed @ Pressure | Max. Coeff. of Friction | Max. Temp., ° F | Max. Pressure, psi | 1 ft. Long | 2 ft. Long | 3 ft. Long | 4 ft. Long | 5 ft. Long | 6 ft. Long | 10 ft. Long | 15 ft. Long | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Molded | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 1 3/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2 1/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 2 3/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 5" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 6" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1 3/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 2 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 5" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 6" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 0000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 2 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 3" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 2 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 4 1/2" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 6" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 7" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 8" | 4,000 fpm @ 250 psi | 0.47 | 480 | 250 | 00000000 | 00000 | 00000 | 000000 | 000000 | 000000 | 000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||