Filter by

System of Measurement

Thickness

Material

Performance

Maximum Temperature

Clarity

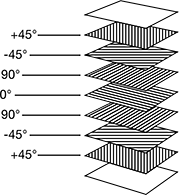

Carbon Fiber Construction

Tensile Strength

DFARS Specialty Metals

Hardness Rating

Hardness

Composite Tensile Stiffness

For Use Outdoors

Fiber Tensile Stiffness Rating

Application

Spark- and Heat-Resistant Blankets

Protects Against Sparks, Welding Spatter, and Molten Metal Splash

|  |  |

Carbon Fiber Pad | Carbon Fiber Blanket | Carbon Fiber Roll |

Wd., ft. | Lg., ft. | Thk., mil | Wt., lb. | Max. Temp., ° F | Color | Specifications Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Scratch-Free Carbon Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pad | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2 | 1 1/2 | 175 | 1 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blanket | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 | 175 | 1 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 | 175 | 3 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 4 | 275 | 4 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 5 | 175 | 3 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6 | 175 | 4 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6 | 275 | 6 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 6 | 175 | 5 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 6 | 275 | 8 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 8 | 175 | 7 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 10 | 175 | 9 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 10 | 175 | 11 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Roll | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 50 | 175 | 22 | 1,800 | Black | ANSI/FM 4950, FM Approved | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Lightweight Carbon Fiber Sheets and Bars

Glossy Checked Sheets

Temp. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Color | Min. | Max., ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 6" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.018" to 0.018" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.025" to 0.025" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.037" to 0.037" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -0.05" to 0.05" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.018" to 0.018" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.025" to 0.025" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.018" to 0.018" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.025" to 0.025" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.037" to 0.037" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | -0.05" to 0.05" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.018" to 0.018" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 48" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | -0.025" to 0.025" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | -0.037" to 0.037" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 48" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/32" | -0.003" to 0.003" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | -0.018" to 0.018" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

36" Wide × 36" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.004" to 0.004" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | -0.008" to 0.008" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain Bars

Thk. | Thk. Tolerance | Wd. | Lg. | Color | Temp. Range, ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.016" | -0.005" to 0.005" | 0.118" | 39" | Black | -100 to 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | |

| 0.039" | -0.005" to 0.005" | 0.118" | 39" | Black | -100 to 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | |

| 0.043" | -0.005" to 0.005" | 0.157" | 39" | Black | -100 to 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 0000 | |

| 0.079" | -0.005" to 0.005" | 0.630" | 39" | Black | -100 to 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 |

Glossy Checked Bars

Temp. | 12" Long | 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Color | Min. | Max., ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/32" Thick (-0.003" to 0.003") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/16" Thick (-0.004" to 0.004") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 0000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/8" Thick (-0.006" to 0.006") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/16" Thick (-0.006" to 0.006") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Thick (-0.008" to 0.008") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Thick (-0.018" to 0.018") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Thick (-0.025" to 0.025") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Thick (-0.037" to 0.037") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Thick (-0.05" to 0.05") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | Black | Not Rated | 180 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 00000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Back Checked Bars

Adhesive | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Lg. | Type | Max. Temp., ° F | Color | Temp. Range, ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

0.02" Thick (-0.01" to 0.01") | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 48" | Acrylate | 210 | Black | 0 to 190 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 48" | Acrylate | 210 | Black | 0 to 190 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 48" | Acrylate | 210 | Black | 0 to 190 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 48" | Acrylate | 210 | Black | 0 to 190 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength Lightweight Carbon Fiber Sheets with Foam Core

12" Wide × 12" Long | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Pattern | Color | Temp. Range, ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | |||

| 1/4" | -0.02" to 0.02" | Checked | Black | 0 to 250 | 120,000 psi to 175,000 psi (Excellent) | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 0000000 | ||

Rigid High-Strength Lightweight Carbon Fiber Sheets

12" Wide × 24" Long | 24" Wide × 24" Long | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Pattern | Appearance | Fiber Layup Orientation | Color | Temp. Range, ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | Each | ||||

| 1/16" | -0.008" to 0.008" | Checked | Matte | 0°/90° | Black | -65 to 180 | 125,000 psi to 150,000 psi (Excellent) | 57 msi to 63 msi (High Modulus) | Not Rated | Not Rated | No | 00000000 | 0000000 | 00000000 | 0000000 | ||

| 1/8" | -0.012" to 0.012" | Checked | Matte | 0°/90° | Black | -65 to 180 | 125,000 psi to 150,000 psi (Excellent) | 57 msi to 63 msi (High Modulus) | Not Rated | Not Rated | No | 00000000 | 000000 | 00000000 | 000000 | ||

Carbon Fiber Sheets

48" Wide × 36" Long | 50" Wide × 36" Long | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Color | Temp. Range, ° F | Fiber Tensile Stiffness | For Use Outdoors | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Unidirectional Weave | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.014" | Black | 0 to 250 | 33 msi to 36 msi (Standard) | No | ——— | 0 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plain Weave | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.012" | Black | 0 to 250 | 33 msi to 36 msi (Standard) | No | ——— | 0 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twill Weave | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.012" | Black | 0 to 250 | 33 msi to 36 msi (Standard) | No | ——— | 0 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.025" | Black | 0 to 250 | 33 msi to 36 msi (Standard) | No | ——— | 0 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triaxial Weave | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.027" | Black | 0 to 250 | 33 msi to 36 msi (Standard) | No | 0000000 | 0000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Thermoform High-Strength Chemical-Resistant PAEK and Carbon Fiber Sheets

12" Wide × 12" Long | 16" Wide × 16" Long | 24" Wide × 24" Long | 32" Wide × 32" Long | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Appearance | Color | Max. Temp., ° F | Tensile Strength, psi | Impact Strength | For Use Outdoors | Each | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bidirectional Carbon Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.066" | -0.007" to 0.007" | Plain | Black | 500 | 275,550 | Not Rated | No | ——— | 0 | 0000000 | 0000000 | ——— | 0 | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quasi-Isotropic Carbon Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.044" | -0.004" to 0.004" | Plain | Black | 500 | 94,850 | Not Rated | No | 0000000 | 0000000 | ——— | 0 | 0000000 | 000000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.088" | -0.009" to 0.009" | Plain | Black | 500 | 94,850 | Not Rated | No | 0000000 | 000000 | ——— | 0 | 0000000 | 00000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Impact-Resistant High-Strength Carbon Fiber Sheets with Kevlar Core

12" Wide × 12" Long | 24" Wide × 24" Long | 24" Wide × 48" Long | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | Pattern | Appearance | Color | Temp. Range, ° F | Tensile Strength | Impact Strength | Hardness | For Use Outdoors | Each | Each | Each | |||||

| 0.06" | -0.03" to 0.03" | Checked | Glossy | Black | -100 to 190 | 177,000 psi (Excellent) | Not Rated | Not Rated | No | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||

| 0.09" | -0.03" to 0.03" | Checked | Glossy | Black | -100 to 190 | 177,000 psi (Excellent) | Not Rated | Not Rated | No | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | ||

Warp-Resistant High-Strength Lightweight Carbon Fiber Sheets

Thk. | Thk. Tolerance | Pattern | Appearance | Color | Max. Temp., ° F | Tensile Strength | Fiber Tensile Stiffness | Impact Strength | Hardness | For Use Outdoors | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Quasi-Isotropic Carbon Fiber | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.003" to 0.003" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.003" to 0.003" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

24" Wide × 24" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | -0.003" to 0.003" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | -0.006" to 0.006" | Checked | Glossy | Black | 180 | Not Rated | 33 msi to 36 msi (Standard) | Not Rated | Not Rated | No | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Honeycomb

Wd. | Lg. | Honeycomb Cell Size | Cell Wall Thk. | Face Thk. | Max. Load Cap. | Deflection @ lb. Load | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

5052 Panels with Carbon Fiber Face | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Thick (-0.005" to 0.005" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 48" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Thick (-0.005" to 0.005" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 48" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" Thick (-0.005" to 0.005" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 48" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1" Thick (-0.005" to 0.005" Tolerance) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 12" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 24" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24" | 48" | 1/8" | 0.003" | 0.02" | Not Rated | Not Rated | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||