Selecting Compatible Lead Screws and Nuts

More

About Flat Head Screws

More

About Rounded Head Screws

More

About Socket Head Screws

More

Plastic Socket Head Screws

These screws are chemical and oil resistant, nonconductive, and lightweight. Length is measured from under the head. PEEK screws are twice as strong as standard nylon screws and withstand temperatures up to 500° F. They resist more chemicals than polypropylene screws.

Coarse threads are the industry standard; choose these screws if you don’t know the pitch or threads per inch. Fine threads are closely spaced to prevent loosening from vibration. They are not compatible with coarse threads.

Screws that meet ASME B18.3 comply with specifications for dimensional standards.

Head | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Threading | Thread Spacing | Dia. | Ht. | Drive Size | Temp. Range, °F | Color | Specifications Met | Each | |

PEEK Plastic | ||||||||||

2-56 | ||||||||||

| 3/16" | Fully Threaded | Coarse | 9/64" | 0.086" | 5/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 00000 |

| 1/4" | Fully Threaded | Coarse | 9/64" | 0.086" | 5/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Coarse | 9/64" | 0.086" | 5/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

4-40 | ||||||||||

| 3/16" | Fully Threaded | Coarse | 0.183" | 0.112" | 3/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/4" | Fully Threaded | Coarse | 0.183" | 0.112" | 3/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 5/16" | Fully Threaded | Coarse | 0.183" | 0.112" | 3/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/8" | Fully Threaded | Coarse | 0.183" | 0.112" | 3/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Coarse | 0.183" | 0.112" | 3/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

6-32 | ||||||||||

| 1/4" | Fully Threaded | Coarse | 0.226" | 0.138" | 7/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/8" | Fully Threaded | Coarse | 0.226" | 0.138" | 7/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Coarse | 0.226" | 0.138" | 7/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 5/8" | Fully Threaded | Coarse | 0.226" | 0.138" | 7/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 0.226" | 0.138" | 7/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

8-32 | ||||||||||

| 1/4" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/8" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 5/8" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 1/2" | Fully Threaded | Coarse | 0.27" | 0.164" | 9/64" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

10-24 | ||||||||||

| 1/2" | Fully Threaded | Coarse | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

10-32 | ||||||||||

| 3/8" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 5/8" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 1/4" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 1/2" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 2" | Fully Threaded | Fine | 5/16" | 0.19" | 5/32" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

1/4"-20 | ||||||||||

| 3/8" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1/2" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 5/8" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 7/8" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 1/4" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 1/2" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1 3/4" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 2" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 2 1/2" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3" | Fully Threaded | Coarse | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

1/4"-28 | ||||||||||

| 3/8" | Fully Threaded | Fine | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Fine | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Fine | 3/8" | 1/4" | 3/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

5/16"-18 | ||||||||||

| 1/2" | Fully Threaded | Coarse | 15/32" | 5/16" | 1/4" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 15/32" | 5/16" | 1/4" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Coarse | 15/32" | 5/16" | 1/4" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

3/8"-16 | ||||||||||

| 1/2" | Fully Threaded | Coarse | 9/16" | 3/8" | 5/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 3/4" | Fully Threaded | Coarse | 9/16" | 3/8" | 5/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 1" | Fully Threaded | Coarse | 9/16" | 3/8" | 5/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 0000 |

| 2" | Fully Threaded | Coarse | 9/16" | 3/8" | 5/16" | -50° to 500° | Beige | ASME B18.3, UL 94 V-0 | 000000000 | 00000 |

M3 × 0.5mm | ||||||||||

| 5mm | Fully Threaded | Coarse | 5.5mm | 3mm | 2.5 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 6mm | Fully Threaded | Coarse | 5.5mm | 3mm | 2.5 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

M4 × 0.7mm | ||||||||||

| 8mm | Fully Threaded | Coarse | 7mm | 4mm | 3 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 10mm | Fully Threaded | Coarse | 7mm | 4mm | 3 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 12mm | Fully Threaded | Coarse | 7mm | 4mm | 3 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 14mm | Fully Threaded | Coarse | 7mm | 4mm | 3 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 16mm | Fully Threaded | Coarse | 7mm | 4mm | 3 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

M5 × 0.8mm | ||||||||||

| 10mm | Fully Threaded | Coarse | 8.5mm | 5mm | 4 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 12mm | Fully Threaded | Coarse | 8.5mm | 5mm | 4 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 20mm | Fully Threaded | Coarse | 8.5mm | 5mm | 4 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 25mm | Fully Threaded | Coarse | 8.5mm | 5mm | 4 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

M6 × 1mm | ||||||||||

| 12mm | Fully Threaded | Coarse | 10mm | 6mm | 5 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 20mm | Fully Threaded | Coarse | 10mm | 6mm | 5 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 25mm | Fully Threaded | Coarse | 10mm | 6mm | 5 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

M8 × 1.25mm | ||||||||||

| 16mm | Fully Threaded | Coarse | 13mm | 8mm | 6 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 20mm | Fully Threaded | Coarse | 13mm | 8mm | 6 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 25mm | Fully Threaded | Coarse | 13mm | 8mm | 6 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

| 30mm | Fully Threaded | Coarse | 13mm | 8mm | 6 mm | -50° to 500° | Beige | DIN 912, UL 94 V-0 | 000000000 | 0000 |

Metric High-Strength High-Temperature PEEK Pan Head Phillips Screws

PEEK screws are reliable in harsh environments up to 500° F and withstand acids, bases, and salt solutions. All are chemical and oil resistant, nonconductive, and lightweight. Length is measured from under the head.

| Lg., mm | Threading | Head Dia., mm | Head Ht., mm | Drive Size | Temperature Range, °F | Color | Specifications Met | Pkg. Qty. | Pkg. | |

PEEK Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

M2 × 0.4 mm | ||||||||||

| 4 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 000000 |

| 5 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 6 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 8 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 10 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

M2.5 × 0.45 mm | ||||||||||

| 4 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 5 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 6 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 8 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

| 10 | Fully Threaded | 5.00 | 1.40 | No. 0 | -50° to 500° | Beige | ASME B18.6.7M | 10 | 000000000 | 00000 |

M3 × 0.5 mm | ||||||||||

| 5 | Fully Threaded | 5.40 | 1.50 | No. 1 | -50° to 500° | Beige | __ | 10 | 000000000 | 00000 |

| 6 | Fully Threaded | 5.40 | 1.50 | No. 1 | -50° to 500° | Beige | __ | 10 | 000000000 | 00000 |

| 8 | Fully Threaded | 5.40 | 1.50 | No. 1 | -50° to 500° | Beige | __ | 10 | 000000000 | 00000 |

| 10 | Fully Threaded | 5.40 | 1.50 | No. 1 | -50° to 500° | Beige | __ | 5 | 000000000 | 0000 |

| 12 | Fully Threaded | 5.40 | 1.50 | No. 1 | -50° to 500° | Beige | __ | 5 | 000000000 | 0000 |

| 16 | Fully Threaded | 5.40 | 1.50 | No. 0 | -50° to 500° | Beige | __ | 5 | 000000000 | 0000 |

| 20 | Fully Threaded | 5.40 | 1.50 | No. 0 | -50° to 500° | Beige | __ | 5 | 000000000 | 0000 |

M4 × 0.7 mm | ||||||||||

| 6 | Fully Threaded | 8.00 | 2.50 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 0000 |

| 8 | Fully Threaded | 8.00 | 2.50 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 0000 |

| 10 | Fully Threaded | 8.00 | 2.50 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 0000 |

| 12 | Fully Threaded | 8.00 | 2.50 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 00000 |

| 16 | Fully Threaded | 8.00 | 2.50 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 00000 |

| 20 | Fully Threaded | 8.00 | 2.50 | No. 1 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 00000 |

| 25 | Fully Threaded | 8.00 | 2.50 | No. 1 | -50° to 500° | Beige | ASME B18.6.7M | 5 | 000000000 | 00000 |

M5 × 0.8 mm | ||||||||||

| 8 | Fully Threaded | 9.40 | 2.70 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 10 | Fully Threaded | 9.40 | 2.70 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 12 | Fully Threaded | 9.40 | 2.70 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 16 | Fully Threaded | 9.40 | 2.70 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 20 | Fully Threaded | 9.40 | 2.70 | No. 2 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

M6 × 1 mm | ||||||||||

| 10 | Fully Threaded | 12.00 | 3.30 | No. 3 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 12 | Fully Threaded | 12.00 | 3.30 | No. 3 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 16 | Fully Threaded | 12.00 | 3.30 | No. 3 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 20 | Fully Threaded | 12.00 | 3.30 | No. 3 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

| 25 | Fully Threaded | 12.00 | 3.30 | No. 3 | -50° to 500° | Beige | ASME B18.6.7M | 1 | 000000000 | 0000 |

High-Strength High-Temperature PEEK Pan Head Phillips Screws

Reliable in harsh environments up to 500° F, PEEK screws withstand acids, bases, and salt solutions. They are chemical and oil resistant, nonconductive, and lightweight. Length is measured from under the head.

| Lg. | Threading | Head Dia. | Head Ht. | Drive Size | Temperature Range, °F | Color | Specifications Met | Pkg. Qty. | Pkg. | |

PEEK Plastic | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

2-56 | ||||||||||

| 3/16" | Fully Threaded | 0.195" | 0.070" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 000000 |

| 1/4" | Fully Threaded | 0.195" | 0.070" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 3/8" | Fully Threaded | 0.195" | 0.070" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 1/2" | Fully Threaded | 0.195" | 0.070" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

4-40 | ||||||||||

| 3/16" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 0000 |

| 1/4" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 5/16" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 3/8" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 1/2" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 3/4" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 5 | 000000000 | 00000 |

| 1" | Fully Threaded | 0.210" | 0.080" | No. 1 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

6-32 | ||||||||||

| 1/4" | Fully Threaded | 0.270" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 5/16" | Fully Threaded | 0.268" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/8" | Fully Threaded | 0.268" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.268" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.268" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1" | Fully Threaded | 0.270" | 0.097" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

8-32 | ||||||||||

| 1/4" | Fully Threaded | 0.320" | 0.115" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/8" | Fully Threaded | 0.314" | 0.115" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.314" | 0.115" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.314" | 0.115" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1" | Fully Threaded | 0.320" | 0.115" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

10-32 | ||||||||||

| 1/4" | Fully Threaded | 0.370" | 0.133" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/8" | Fully Threaded | 0.370" | 0.133" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.370" | 0.133" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.370" | 0.133" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1" | Fully Threaded | 0.370" | 0.133" | No. 2 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

1/4"-20 | ||||||||||

| 3/8" | Fully Threaded | 0.490" | 0.175" | No. 3 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.490" | 0.175" | No. 3 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.490" | 0.175" | No. 3 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

| 1" | Fully Threaded | 0.490" | 0.175" | No. 3 | -60° to 500° | Beige | ASME B18.6.3 | 1 | 000000000 | 0000 |

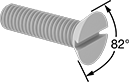

High-Strength High-Temperature PEEK Slotted Flat Head Screws

These screws are more reliable in high-stress, high-temperature environments than other plastic screws. They withstand water, steam, and temperatures up to 500° F. They’re angled under the head to sit flush within countersunk holes. Length is measured from the top of the head.

| Lg. | Threading | Head Dia. | Head Ht. | Temperature Range, °F | Color | Specifications Met | Each | |

PEEK Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

6-32 | ||||||||

| 3/8" | Fully Threaded | 0.268" | 0.082" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 00000 |

| 1/2" | Fully Threaded | 0.268" | 0.082" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.268" | 0.082" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

8-32 | ||||||||

| 3/8" | Fully Threaded | 0.314" | 0.096" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.314" | 0.096" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.314" | 0.096" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

10-32 | ||||||||

| 3/8" | Fully Threaded | 0.370" | 0.100" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

| 1/2" | Fully Threaded | 0.370" | 0.100" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

| 3/4" | Fully Threaded | 0.370" | 0.100" | -50° to 500° | Beige | ASME B18.6.3 | 000000000 | 0000 |

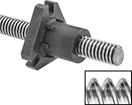

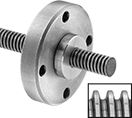

Metric Fast-Travel Ultra-Precision Lead Screws and Nuts

Multiple thread channels (also known as thread starts) create faster linear travel than lead screws with a single thread start. Operating with less backlash (play) than Metric Precision Acme Lead Screws and Nuts, these lead screws and nuts provide increased nut life and more reliable movement in automated systems. To ensure compatibility, select components that have the same thread size, thread pitch, and number of thread starts.

Flange nuts with a wear-compensating internal O-ring resist backlash to keep the nuts in place and maintain a tight fit even when their threads begin to wear. They’re often used in 3D printing and robotic applications.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

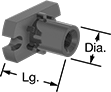

External Thread | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg. | Wd. | Ht. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Size | Lg. | Dynamic Thrust Load Cap., lbs. | Each | ||

PEEK Plastic | ||||||||||||||

| C | M2 | 0.4 | 5/16" | 0.22" | 0.197" | 2 | Metric Rounded Trapezoidal | 2:1 | 0.75 | M5 | 9/64" | 2 | 00000000 | 000000 |

| C | M2 | 0.4 | 5/16" | 0.22" | 0.197" | 4 | Metric Rounded Trapezoidal | 4:1 | 1.5 | M5 | 9/64" | 2 | 00000000 | 00000 |

| C | M2 | 0.4 | 5/16" | 0.22" | 0.197" | 8 | Metric Rounded Trapezoidal | 8:1 | 3 | M5 | 9/64" | 2 | 00000000 | 00000 |

| C | M3 | 0.5 | 13/32" | 0.311" | 0.276" | 2 | Metric Rounded Trapezoidal | 2:1 | 1 | M7 | 5/32" | 4 | 00000000 | 00000 |

| C | M3 | 0.5 | 13/32" | 0.311" | 0.276" | 6 | Metric Rounded Trapezoidal | 6:1 | 3 | M7 | 5/32" | 4 | 00000000 | 00000 |

| C | M4 | 1 | 1/2" | 0.402" | 0.354" | 4 | Metric Rounded Trapezoidal | 4:1 | 4 | M9 | 13/64" | 4 | 00000000 | 00000 |

| C | M4 | 1 | 1/2" | 0.402" | 0.354" | 8 | Metric Rounded Trapezoidal | 8:1 | 8 | M9 | 13/64" | 10 | 00000000 | 00000 |

Flange | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Thread Pitch, mm | Lg. | Dia. | Wd. | Ht. | Thick. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Bolt Circle Dia. | Dynamic Thrust Load Cap., lbs. | Each | ||

PEEK Plastic | |||||||||||||||

| D | M2 | 0.4 | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | 2 | Metric Rounded Trapezoidal | 2:1 | 0.75 | 11/32" | 2 | 00000000 | 000000 |

| D | M2 | 0.4 | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | 4 | Metric Rounded Trapezoidal | 4:1 | 1.5 | 11/32" | 2 | 00000000 | 00000 |

| D | M2 | 0.4 | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | 8 | Metric Rounded Trapezoidal | 8:1 | 3 | 11/32" | 2 | 00000000 | 00000 |

| D | M3 | 0.5 | 21/64" | 0.295" | 39/64" | 5/16" | 3/32" | 2 | Metric Rounded Trapezoidal | 2:1 | 1 | 15/32" | 4 | 00000000 | 00000 |

| D | M3 | 0.5 | 21/64" | 0.295" | 39/64" | 5/16" | 3/32" | 6 | Metric Rounded Trapezoidal | 6:1 | 3 | 15/32" | 4 | 00000000 | 00000 |

| D | M3 | 0.5 | 21/64" | 0.295" | 39/64" | 5/16" | 3/32" | 12 | Metric Rounded Trapezoidal | 12:1 | 6 | 15/32" | 4 | 00000000 | 00000 |

| D | M4 | 1 | 13/32" | 0.354" | 3/4" | 13/32" | 1/8" | 4 | Metric Rounded Trapezoidal | 4:1 | 4 | 19/32" | 10 | 00000000 | 00000 |

| D | M4 | 1 | 13/32" | 0.354" | 3/4" | 13/32" | 1/8" | 8 | Metric Rounded Trapezoidal | 8:1 | 8 | 19/32" | 10 | 00000000 | 00000 |

PEEK Plastic with Wear-Compensating Internal O-Ring | |||||||||||||||

| D | M2 | 0.4 | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | 2 | Metric Rounded Trapezoidal | 2:1 | 0.75 | 11/32" | 1 | 00000000 | 00000 |

| D | M2 | 0.4 | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | 4 | Metric Rounded Trapezoidal | 4:1 | 1.5 | 11/32" | 1 | 00000000 | 00000 |

| D | M2 | 0.4 | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | 8 | Metric Rounded Trapezoidal | 8:1 | 3 | 11/32" | 1 | 00000000 | 00000 |

| D | M3 | 0.5 | 25/64" | 0.315" | 39/64" | 5/16" | 3/32" | 2 | Metric Rounded Trapezoidal | 2:1 | 1 | 15/32" | 2 | 00000000 | 00000 |

| D | M3 | 0.5 | 25/64" | 0.315" | 39/64" | 5/16" | 3/32" | 6 | Metric Rounded Trapezoidal | 6:1 | 3 | 15/32" | 2 | 00000000 | 00000 |

| D | M3 | 0.5 | 25/64" | 0.315" | 39/64" | 5/16" | 3/32" | 12 | Metric Rounded Trapezoidal | 12:1 | 6 | 15/32" | 2 | 00000000 | 00000 |

| D | M4 | 1 | 31/64" | 0.406" | 3/4" | 13/32" | 1/8" | 4 | Metric Rounded Trapezoidal | 4:1 | 4 | 19/32" | 4 | 00000000 | 00000 |

| D | M4 | 1 | 31/64" | 0.406" | 3/4" | 13/32" | 1/8" | 8 | Metric Rounded Trapezoidal | 8:1 | 8 | 19/32" | 4 | 00000000 | 00000 |

Metric Ultra-Precision Lead Screws and Nuts

Operating with less backlash (play) than Metric Precision Acme Lead Screws and Nuts, these provide increased nut life and more reliable movement in automated systems. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won't unexpectedly move when the lead screw is at rest. To ensure compatibility, select components that have the same thread size, thread type, thread size, thread pitch, and number of thread starts.

Flange nuts with wear-compensating internal O-ring maintain a tight fit even when their threads begin to wear. They resist backlash to maintain accuracy over time, which is important in positioning applications such as 3D printing and robotics.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

External Thread | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

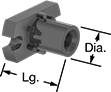

| Thread Size | Thread Pitch, mm | Lg. | Wd. | Ht. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Size | Pitch | Lg. | Dynamic Thrust Load Cap., lbs. | Each | ||

PEEK Plastic | |||||||||||||||

| B | M2 | 0.4 | 5/16" | 0.22" | 0.197" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.375 | M5 | 0.8mm | 9/64" | 2 | 000000000 | 000000 |

| B | M3 | 0.5 | 13/32" | 0.311" | 0.276" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.5 | M7 | 0.75mm | 5/32" | 5 | 000000000 | 00000 |

| B | M4 | 1 | 1/2" | 0.402" | 0.354" | 1 | Metric Rounded Trapezoidal | 1:1 | 1 | M9 | 1mm | 13/64" | 10 | 000000000 | 00000 |

Flange | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

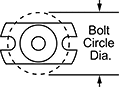

| Thread Size | Thread Pitch, mm | Lg. | Dia. | Wd. | Ht. | Thick. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn, mm | Bolt Circle Dia. | Dynamic Thrust Load Cap., lbs. | Each | ||

PEEK Plastic | |||||||||||||||

| C | M2 | 0.4 | 9/32" | 0.209" | 15/32" | 15/64" | 5/64" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.375 | 11/32" | 2 | 000000000 | 000000 |

| C | M3 | 0.5 | 21/64" | 0.295" | 39/64" | 5/16" | 3/32" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.5 | 15/32" | 5 | 000000000 | 00000 |

| C | M4 | 1 | 13/32" | 0.354" | 3/4" | 13/32" | 1/8" | 1 | Metric Rounded Trapezoidal | 1:1 | 1 | 19/32" | 10 | 000000000 | 00000 |

PEEK Plastic with Wear-Compensating Internal O-Ring | |||||||||||||||

| C | M2 | 0.4 | 5/16" | 0.228" | 15/32" | 15/64" | 5/64" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.375 | 11/32" | 1 | 000000000 | 000000 |

| C | M3 | 0.5 | 25/64" | 0.315" | 39/64" | 5/16" | 3/32" | 1 | Metric Rounded Trapezoidal | 1:1 | 0.5 | 15/32" | 2 | 000000000 | 000000 |

| C | M4 | 1 | 31/64" | 0.406" | 3/4" | 13/32" | 1/8" | 1 | Metric Rounded Trapezoidal | 1:1 | 1 | 19/32" | 5 | 000000000 | 000000 |

Precision Acme Lead Screws and Nuts

Pair with a motor in automated motion and positioning applications. A tight thread fit allows these lead screws and nuts to make accurate, repeatable starts and stops. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won’t unexpectedly move when the lead screw is at rest. To ensure compatibility, please select components that have the same thread direction, thread size, and number of thread starts.

Carbon steel lead screws and flanges have good machinability. Black-oxide alloy steel lead screws are hard and strong. They have mild corrosion resistance and a dark surface color. 303 and 304 stainless steel lead screws and flanges have good corrosion resistance.

PEEK plastic nuts handle twice as much heat as PET and acetal plastic nuts. They have good chemical resistance and excellent corrosion resistance.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PEEK Plastic | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2"-10 | 1" | 1.5" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 5,650 | -40° to 525° | 000000000 | 0000000 |

Combine externally threaded nuts with a flange to create a custom flange nut.

External Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

PEEK Plastic | |||||||||||||

| 1/4"-20 | 5/8" | 0.688" | 1 | 1:1 | 0.05" | 9/16"-18 | 3/8" | Class 2C | Not Rated | 150 | -40° to 525° | 000000000 | 0000000 |

| 1/2"-10 | 3/4" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 620 | -40° to 525° | 000000000 | 000000 |

| 3/4"-5 | 1 1/4" | 1.125" | 1 | 1:1 | 0.2" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,400 | -40° to 525° | 000000000 | 000000 |

| 3/4"-6 | 1 1/4" | 1.125" | 1 | 1:1 | 0.166" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,400 | -40° to 525° | 000000000 | 000000 |

| 3/4"-10 | 1 1/4" | 1.125" | 1 | 1:1 | 0.1" | 1"-18 | 1/2" | Class 2C | Not Rated | 1,400 | -40° to 525° | 000000000 | 000000 |

| 1"-4 | 1 1/2" | 1.5" | 1 | 1:1 | 0.25" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | -40° to 525° | 000000000 | 000000 |

| 1"-5 | 1 1/2" | 1.5" | 1 | 1:1 | 0.2" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | -40° to 525° | 000000000 | 000000 |

| 1"-10 | 1 1/2" | 1.5" | 1 | 1:1 | 0.1" | 1 3/8"-16 | 1/2" | Class 2C | Not Rated | 2,500 | -40° to 525° | 000000000 | 000000 |

| 1 1/4"-5 | 1 3/4" | 2.125" | 1 | 1:1 | 0.2" | 1 31/32"-18 | 13/16" | Class 2C | Not Rated | 3,900 | -40° to 525° | 000000000 | 000000 |

Thread onto an externally threaded acme nut to create a custom flange nut.

Carbon steel flanges have good machinability. However, they will rust when exposed to moisture. Black-oxide carbon steel flanges have mild corrosion resistance in dry environments and a dark surface color. 303 stainless steel flanges have good corrosion resistance.

| Flange Thread Size | Flange Dia. | Flange Thick. | Bolt Circle Dia. | Flange Hardness | Each | |

1117 Carbon Steel | ||||||

|---|---|---|---|---|---|---|

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 156 | 000000000 | 000000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 156 | 000000000 | 00000 |

Black-Oxide 1117 Carbon Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 135 | 00000000 | 00000 |

| 15/16"-16 | 2 39/64" | 17/32" | 2 3/32" | Brinell 135 | 00000000 | 00000 |

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 135 | 00000000 | 00000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 135 | 00000000 | 00000 |

1215 Carbon Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Not Rated | 000000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 |

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Not Rated | 000000000 | 00000 |

303 Stainless Steel | ||||||

| 9/16"-18 | 1 39/64" | 13/32" | 1 1/8" | Brinell 140 | 0000000 | 00000 |

| 15/16"-16 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 |

| 1"-18 | 2 5/8" | 17/32" | 2 3/32" | Brinell 140 | 0000000 | 00000 |

| 1 3/8"-16 | 2 49/64" | 33/64" | 2 17/64" | Brinell 140 | 0000000 | 00000 |

| 1 31/32"-18 | 4 13/64" | 53/64" | 3 7/16" | Brinell 140 | 0000000 | 000000 |