How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Crack-Resistant PFA Pipe Fittings for Chemicals

- For Use With: Acetic Acid, Alcohol, Salt Water

- Max. Temperature: 150° F

Not only do these PFA fittings have the chemical resistance to handle acid and salt water, they also have better crack resistance than other plastic pipe fittings for chemicals. Also known as Schedule 80 fittings, they have thick, strong walls to handle heavy duty chemical processing applications. Fittings have a super-smooth interior for unrestricted flow. They are commonly used in high-purity chemical flow processes, such as semiconductor and clean room applications, because the material won’t leach contaminates into the line. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To connect, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

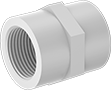

| Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

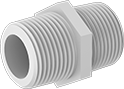

| Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

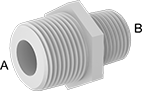

| Pipe Size (A) | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 3/8 | 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 1/4 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 3/8 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1/2 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

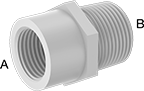

| Pipe Size (A) | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/8 | 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 1/4 | 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 3/8 | 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

| Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |

| 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

| Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |

| 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

| Pipe Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/4 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 00000 |

| 3/8 | PFA Plastic | White | 120 psi @ 72° F | 000000000 | 000000 |

| 1/2 | PFA Plastic | White | 100 psi @ 72° F | 000000000 | 000000 |

| 3/4 | PFA Plastic | White | 70 psi @ 72° F | 000000000 | 000000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

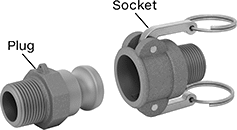

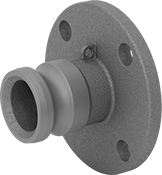

Metal Cam-and-Groove Hose Couplings for Water

A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug.

Aluminum couplings are lighter in weight than brass plugs and sockets. They have good abrasion and corrosion resistance thanks to their anodized finish.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Specifications Met: ASME B16.5, Fed. Spec. A-A-59326

- Compatible With: Andrews Cam-and-Groove Couplings, Dixon Cam-and-Groove Couplings, Ever-Tite Cam-and-Groove Couplings, PT Coupling Cam-and-Groove Couplings

Plugs with flanged end are also known as PFA adapters. Bolt the flanged end to another same-size flange with a gasket (sold separately).

Bolt Holes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Plug OD | Pipe Size | Flange OD | Flanged Connection Surface | Pressure Class | Max. Pressure | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

Anodized Aluminum | ||||||||||||

| 2 | 2 1/2" | 2 | 6" | Flat | 150 | 250 psi @ 72° F | 5/8" | 3/4" | 4 | 4 3/4" | 00000000 | 0000000 |

| 3 | 3 5/8" | 3 | 7 1/2" | Flat | 150 | 200 psi @ 72° F | 5/8" | 3/4" | 4 | 6" | 00000000 | 000000 |

| 4 | 4 3/4" | 4 | 9" | Flat | 150 | 150 psi @ 72° F | 5/8" | 3/4" | 8 | 7 1/2" | 00000000 | 000000 |

| 6 | 6 15/16" | 6 | 11" | Flat | 150 | 75 psi @ 72° F | 3/4" | 7/8" | 8 | 9 1/2" | 00000000 | 000000 |

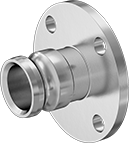

Metal Cam-and-Groove Hose Couplings for Chemicals and Petroleum

Made of metal, these couplings have better durability than plastic cam-and-groove couplings. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Couplings are compatible with Andrews, Dixon, Ever-Tite, and PT cam-and-groove couplings.

Aluminum fittings are lighter in weight than 316 stainless steel fittings. They have good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- For Use With: Citric Acid, Diesel Fuel, Gasoline, Hydraulic Fluid

- Maximum Pressure: See table

- Temperature Range: -65° to 250° F

- Compatible With: Andrews Cam-and-Groove, Dixon Cam-and-Groove, Ever-Tite Cam-and-Groove, PT Coupling Cam-and-Groove

- Specifications Met:

Aluminum: ASME B16.24, Fed. Spec. A-A-59326

316 Stainless Steel: ASME B16.5, Fed. Spec. A-A-59326

Plugs with flanged end are also known as PFA adapters. Bolt the flanged end to another same-size flange with a gasket.

Bolt Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Coupling Size | Plug OD | Pipe Size | Dash Size | Flange OD | Flanged Connection Surface | Pressure Class | Max. Pressure | For Bolt Dia. | Dia. | No. of | Bolt Circle Dia. | Each | |

Aluminum | |||||||||||||

| 2 | 2 1/2" | 2 | 32 | 6" | Flat | 150 | 250 psi @ 72° F | 5/8" | 3/4" | 4 | 4 3/4" | 000000000 | 000000 |

| 3 | 3 5/8" | 3 | 48 | 7 1/2" | Flat | 150 | 200 psi @ 72° F | 5/8" | 3/4" | 4 | 6" | 000000000 | 000000 |

| 4 | 4 3/4" | 4 | 64 | 9" | Flat | 150 | 150 psi @ 72° F | 5/8" | 3/4" | 8 | 7 1/2" | 000000000 | 000000 |

| 6 | 6 15/16" | 6 | 96 | 11" | Flat | 150 | 75 psi @ 72° F | 3/4" | 7/8" | 8 | 9 1/2" | 000000000 | 000000 |

316 Stainless Steel | |||||||||||||

| 2 | 2 1/2" | 2 | 32 | 6" | Raised | 150 | 250 psi @ 72° F | 5/8" | 3/4" | 4 | 4 3/4" | 000000000 | 000000 |

| 3 | 3 5/8" | 3 | 48 | 7 1/2" | Raised | 150 | 200 psi @ 72° F | 5/8" | 3/4" | 4 | 6" | 000000000 | 000000 |

| 4 | 4 3/4" | 4 | 64 | 9" | Raised | 150 | 150 psi @ 72° F | 5/8" | 3/4" | 8 | 7 1/2" | 000000000 | 000000 |

| 6 | 6 15/16" | 6 | 96 | 11" | Raised | 150 | 75 psi @ 72° F | 3/4" | 7/8" | 8 | 9 1/2" | 000000000 | 000000 |