Filter by

System of Measurement

Thread Size

Shaft Diameter

Thread Length

Mount Type

Pin Type

Shaft Type

Thread Spacing

End Shape

DFARS Specialty Metals

Export Control Classification Number (ECCN)

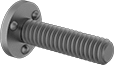

Single-End Studs

Shaft | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Thread Lg. | Lg. | Dia. | Dia. Tolerance | Tensile Strength, psi | Hardness | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/2" | 1/2" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3/4" | 3/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 3/4" | 1 1/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3/4" | 1 3/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3/4" | 2 1/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 3/4" | 2 3/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 3/4" | 3 1/4" | 0.19" | -0.005" to 0.005" | 70,000 | Not Rated | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

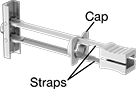

Alignment Locks

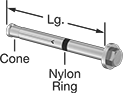

Tapped Taper Pins

T-Bolts with Collar

Head | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Lg. | Threading | Thread Spacing | Wd. | Thk. | Tensile Strength, psi | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3 1/4" | Partially Threaded | Coarse | 1 1/2" | 1/4" | 70,000 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

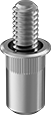

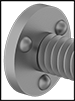

Press-Fit Studs

Lg. | PEM® Part No. | Thread Lg. | For Min. Material Thk. | For Min. Lg. Between Hole Ctr. and Sheet Edge | For Hole Dia. | Hole Size Tolerance | Drill Bit Size | Base Dia. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | FH-024-5 | 7/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | FH-024-6 | 17/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | FH-024-8 | 25/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | FH-024-10 | 33/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | FH-024-12 | 41/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | FH-024-14 | 49/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | FH-024-16 | 57/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 50 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | FH-024-20 | 1 5/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | FH-024-24 | 1 13/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.271" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | FHS-024-6 | 9/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | FHS-024-8 | 13/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | FHS-024-10 | 33/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | FHS-024-12 | 21/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | FHS-024-14 | 49/64" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | FHS-024-16 | 29/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | FHS-024-20 | 1 5/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | FHS-024-24 | 1 13/32" | 0.040" | 9/32" | 0.189" | 0.000" to 0.003" | 12 Ga. | 0.241" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ball-Nose Spring Plungers

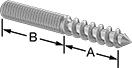

Thread-Mount Studs for Wood

|

(A) | (B) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Screw Size | Thread Lg. | Thread Size | Thread Lg. | Lg. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 7/8" | 10-24 | 5/8" | 1 1/2" | Not Rated | Not Rated | 25 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1" | 10-24 | 1" | 2" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1" | 2 1/2" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1 1/2" | 3" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 7/8" | 10-24 | 5/8" | 1 1/2" | Not Rated | Not Rated | 100 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1" | 10-24 | 1" | 2" | Not Rated | Not Rated | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1" | 2 1/2" | Not Rated | Not Rated | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1 1/2" | 3" | Not Rated | Not Rated | 50 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 5/8" | 10-24 | 3/8" | 1" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 7/8" | 10-24 | 5/8" | 1 1/2" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1" | 10-24 | 1" | 2" | Not Rated | Not Rated | 25 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1" | 2 1/2" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 1 1/2" | 10-24 | 1 1/2" | 3" | Not Rated | Not Rated | 10 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Set Installation Tools for Shallow Female-Threaded Anchors

For Thread Size | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bolt-Style Sleeve Anchors for Block and Brick

Anchors with Hex Head

Thread | Ultimate Strength, lbf | Each | Package | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Size | Lg. | Min. Installation Dp. | Drill Bit Size | Pull-Out | Shear | Conditions Tested In | Installation Torque, ft·lbf | Each | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 10-24 | 3/4" | 1 1/4" | 1/4" | 1,480 | 2,080 | 4,000 psi Concrete | 3 | 000000000 | 00000 | 4 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 10-24 | 3/4" | 1 1/4" | 1/4" | 1,480 | 2,080 | 4,000 psi Concrete | 3 | 000000000 | 0000 | 4 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapped Rounded Machine Keys

Stud Welders

Installation Tools for Shallow Female-Threaded Anchors

For Thread Size | Lg. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 3 1/4" | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

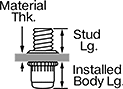

Rivet Studs

Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Material Thk. | Drill Bit Size | Body Dia. | Dia. | Thk. | Installed Body Lg. | Thread Lg. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | 0.02" to 0.13" | 19/64" | 0.296" | 0.415" | 0.030" | 0.38" | 0.5" | Not Rated | Not Rated | 10 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

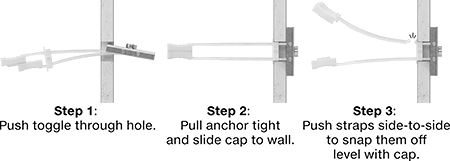

Reusable Anchors for Drywall

Anchors | Installation Tools | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ultimate Strength, lbf | |||||||||||||

Thread Size | Lg. | Usable Lg. | Drill Bit Size | Material | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | Each | |||

| 10-24 | 1 3/4" | 1/2" to 5/8" | 3/8" | Zinc-Plated Steel | 100 | 140 | 3/8" Drywall | 10 | 000000000 | 000000 | 000000000 | 000000 | |

| 10-24 | 2 1/4" | 3/4" to 1 1/8" | 3/8" | Zinc-Plated Steel | 100 | 140 | 3/8" Drywall | 10 | 000000000 | 0000 | 000000000 | 00000 | |

Shallow-Install Anchors for Block and Brick

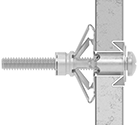

High-Strength Toggle Anchors for Drywall

|  |

Ultimate Strength, lbf | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Thread Size | Usable Lg. | Drill Bit Size | Wing Span | Toggle Material | Material | Fastener Head Type | Drive Style | Pull-Out | Shear | Conditions Tested In | Pkg. Qty. | Pkg. | ||

| 10-24 | 3/8" to 3 5/8" | 1/2" | 2" | Zinc-Plated Steel | Polystyrene | — | — | 230 | 240 | 1/2" Drywall | 10 | 000000000 | 000000 | |

| 10-24 | 3/8" to 3 5/8" | 1/2" | 2" | Zinc-Plated Steel | Polystyrene | Rounded | Phillips/Slotted | 230 | 240 | 1/2" Drywall | 10 | 000000000 | 00000 | |

| 10-24 | 3/8" to 3 5/8" | 1/2" | 2" | Zinc-Plated Steel | Polystyrene | Flat | Phillips | 230 | 240 | 1/2" Drywall | 10 | 000000000 | 00000 | |

| 10-24 | 3/8" to 3 5/8" | 1/2" | 2" | 18-8 Stainless Steel | Polystyrene | — | — | 230 | 240 | 1/2" Drywall | 1 | 000000000 | 0000 | |

| 10-24 | 2" to 9 1/2" | 1/2" | 2" | Zinc-Plated Steel | Polystyrene | — | — | 230 | 240 | 1/2" Drywall | 5 | 000000000 | 00000 | |

| 10-24 | 2" to 9 1/2" | 1/2" | 2" | 18-8 Stainless Steel | Polystyrene | — | — | 230 | 240 | 1/2" Drywall | 1 | 000000000 | 0000 | |

Go/No-Go Left-Hand Threaded Plug Gauges with Handle

Class X Gauge

Thread Size | Thread Type | Pitch Dia. Tolerance | Hardness | Material | Features | For Thread Fit | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Plug Gauges with Accuracy Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Unified Standard Class 2B | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plug Gauges with Calibration Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Unified Standard Class 2B | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld Studs

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Projection Location | Dia. | Thk. | Tensile Strength, psi | Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | Above Head | 0.385" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | Above Head | 0.385" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | Below Head | 0.448" | 0.068" | 60,000 | Not Rated | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Threaded Plug Gauges with Handle

Class X Gauge

Thread Size | Thread Type | Pitch Dia. Tolerance | Hardness | Material | Features | Choose a Thread Fit | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Go/No-Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Unified Standard Class 2B , Unified Standard Class 3B | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Gauges with Calibration Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Unified Standard Class 2B , Unified Standard Class 3B | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Plug Gauges

Class X Gauge

Thread Size | Thread Type | Pitch Dia. Tolerance | Hardness | Material | For Thread Fit | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | 0" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Unified Standard Class 2B, Unified Standard Class 3B | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go Gauges with Accuracy Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | 0" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Unified Standard Class 2B, Unified Standard Class 3B | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0" | Rockwell C70 | Chrome-Plated Tool Steel | Unified Standard Class 2B | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Go Gauges with Accuracy Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0" | Rockwell C70 | Chrome-Plated Tool Steel | Unified Standard Class 2B | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Helical Insert Threaded Plug Gauges with Handle

Plug Gauges with Accuracy Certificate Traceable to NIST | Plug Gauges with Calibration Certificate Traceable to NIST | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Type | Pitch Dia. Tolerance | Hardness | Material | Features | For Thread Fit | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Class X Gauge | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-24 | UNC | -0.0003" to 0.0003" | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Unified Standard Class 2B | 0000000 | 0000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

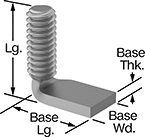

90° Angle Weld Studs

|

Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Lg. | Wd. | Thk. | Tensile Strength | Hardness | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 50 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10-24 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 11/16" | 5/16" | 1/16" | Not Rated | Not Rated | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||