Filter by

System of Measurement

Fastener Head Type

Thread Size

Material

Handle Material

Lock Release

End Type

Performance

Pin Type

Number of Retaining Balls

Export Control Classification Number (ECCN)

Hardness

For Use With

Color

Double Shear Breaking Strength

Handle Color

Mounting Flange Diameter

Mounting Hole Thread Pitch

Mounting Hole Thread Size

REACH

RoHS

DFARS Specialty Metals

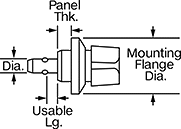

Quick-Release Pins for Blind Holes

Twist Knob

|  |

Quick-Release Pins | Receptacles | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia., mm | Usable Lg., mm | For Panel Thk., mm | Mounting Flange Dia., mm | Double Shear Breaking Strength | Min. Hardness | Handle Color | Handle Material | Ball Material | Mounting Fasteners Included | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 10.5 | 6 to 10 | 25 | Not Rated | Not Rated | Black | Plastic | Stainless Steel | Yes | 000000000 | 000000 | 000000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Plug Gauges

Class X Gauge

Thread Size | Thread Type | Pitch Dia. Tolerance | Hardness | Material | For Thread Fit | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | 0" to 0.0002" | Rockwell C70 | Chrome-Plated Tool Steel | Metric Class 6H | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go Gauges with Accuracy Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | 0" to 0.0002" | Rockwell C70 | Chrome-Plated Tool Steel | Metric Class 6H | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | -0.0002" to 0" | Rockwell C70 | Chrome-Plated Tool Steel | Metric Class 6H | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Go Gauges with Accuracy Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | -0.0002" to 0" | Rockwell C70 | Chrome-Plated Tool Steel | Metric Class 6H | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Threaded Plug Gauges with Handle

Class X Gauge

Thread Size | Thread Type | Pitch Dia. Tolerance, mm | Hardness | Material | Features | For Thread Fit | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Go/No-Go Gauges | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | -0.005 to 0.005 | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Metric Class 6H | 000000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Gauges with Calibration Certificate Traceable to NIST | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 × 0.4 mm | Metric | -0.005 to 0.005 | Rockwell C70 | Chrome-Plated Tool Steel | Double-Ended Taperlock Handle | Metric Class 6H | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||