How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

FM-Approved Low-Pressure Cast Iron Threaded Pipe Fittings

Suitable for use in fire-protection applications, these pipe fittings are made of cast iron, so they are brittle and can be quickly opened with the strike of a sledge hammer. They are also known as Pressure Class 125 fittings. Use in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.4

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | ||||||

|---|---|---|---|---|---|---|

| 1 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

| 1 1/4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 2 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 000000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.4

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | ||||||

|---|---|---|---|---|---|---|

| 1 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 1 1/4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 1 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 0000 |

| 2 1/2 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 3 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

| 4 | Solid | 175 psi @ 72° F | 125 psi @ 350° F | Iron | 000000000 | 00000 |

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.3, ASTM A153, UL Listed

BSPT: ASTM A197, DIN EN 10226 - Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 1 1/4 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 1 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 2 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 3 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 4 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

| 6 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: See table

- Specifications Met:

NPT Steel: SAE J531

NPT Iron: ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed

BSPT: ASTM A197, DIN EN 10226 - Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Plug Construction | Pressure Class | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | |||||||

|---|---|---|---|---|---|---|---|

| 2 1/2 | Hollow | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

| 3 | Hollow | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | 00000000 | 00000 |

| 3 1/2 | Hollow | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

| 4 | Hollow | 125 | 125 psi @ 72° F | 125 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

Medium-Pressure Iron and Steel Threaded Pipe Fittings

With better strength than our low-pressure iron and steel pipe fittings, these can handle medium-pressure applications. They are for use in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 300

- Specifications Met: ASTM A197, UL Listed, ASME B16.3, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 or 600 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female | |||||

|---|---|---|---|---|---|

| 1/4 | 2,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 000000 |

| 3/8 | 2,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 1/2 | 2,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 3/4 | 2,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 1 | 2,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 1 1/4 | 1,500 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 1 1/2 | 1,500 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 2 | 1,500 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 00000 |

| 2 1/2 | 1,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 000000 |

| 3 | 1,000 psi @ 72° F | 300 psi @ 550° F | Iron | 00000000 | 000000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 300

- Specifications Met: See Table

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 or 600 steel

| Pipe Size | Drive Size | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Male | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 1/4" | 2,000 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, ASME B16.14, ASME B16.3, ASTM A197, UL Listed | 0000000 | 00000 |

| 3/8 | 5/16" | 2,000 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, ASME B16.14, ASME B16.3, ASTM A197, UL Listed | 0000000 | 000 |

| 1/2 | 3/8" | 2,000 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, ASME B16.14, ASME B16.3, ASTM A197, UL Listed | 0000000 | 0000 |

| 3/4 | 9/16" | 2,000 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, ASME B16.14, ASME B16.3, ASTM A197, UL Listed | 0000000 | 0000 |

| 1 | 5/8" | 2,000 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, ASME B16.14, ASME B16.3, ASTM A197, UL Listed | 0000000 | 0000 |

| 1 1/2 | 1" | 1,500 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, UL Listed | 00000000 | 00000 |

| 2 | 1" | 1,500 psi @ 72° F | 300 psi @ 550° F | Steel | ASME B1.20.1, UL Listed | 00000000 | 00000 |

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 300

- Specifications Met: See Table

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Male | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 3/4 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 0000 |

| 1 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 0000 |

| 1 1/4 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 1 1/2 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

| 2 1/2 | Solid | 400 psi @ 72° F | 300 psi @ 550° F | Iron | ASME B1.20.1, ASME B16.14, ASTM A126, UL Listed | 00000000 | 00000 |

Grooved-End Iron Pipe Fittings

The grooved ends on these fittings connect to pipe with a clamp to easily install piping systems. Since there’s no heat or threading required, they provide quick access to a pipe line for routine maintenance. Fittings are also known as Victaulic fittings. They are for use in noncorrosive applications.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water

- Temperature Range: -30° to 250° F

- Specifications Met: UL Listed, FM Approved, ASTM A536

| Pipe Size | Max. Pressure | Color | Material | Each | |

| 2 | 750 psi @ 72° F | Orange | Enamel-Coated Ductile Iron | 0000000 | 000000 |

| 2 1/2 | 750 psi @ 72° F | Orange | Enamel-Coated Ductile Iron | 00000000 | 00000 |

| 3 | 750 psi @ 72° F | Orange | Enamel-Coated Ductile Iron | 0000000 | 00000 |

| 4 | 750 psi @ 72° F | Orange | Enamel-Coated Ductile Iron | 0000000 | 00000 |

| 6 | 750 psi @ 72° F | Orange | Enamel-Coated Ductile Iron | 00000000 | 000000 |

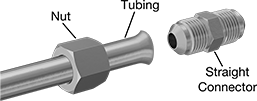

45° Flared Fittings for Copper and Brass Tubing

- Temperature Range: -65° to 250° F

- Tubing: Use with seamless brass and copper that meets ASTM B280

No sleeve is required to assemble these fittings, which makes for a faster, more convenient installation compared to 37° flared fittings. They require a nut (sold separately) for each tube end. Fittings are also known as refrigeration and SAE fittings. They are brass for good corrosion resistance.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water;

except caps for 1/8" tube OD are only for use with refrigerant - Specifications Met: See table

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Specifications Met | Each | |

| 3/16" | 0.03" | Brass | 1,900 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

| 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 5/16" | 0.032" | Brass | 1,200 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 1/2" | 0.032" | Brass | 750 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 5/8" | 0.035" | Brass | 650 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 0000 |

| 3/4" | 0.035" | Brass | 550 psi @ 72° F | SAE J512, SAE J513, UL Listed | 000000000 | 00000 |

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water

- Specifications Met: SAE J512, SAE J513, UL Listed

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Mineral Oil, Refrigerant, Water; except nuts for 1" tube OD are not for use with fuel oil

- Specifications Met: SAE J512, SAE J513, UL Listed; except nuts for 1" tube OD meet SAE J512 and SAE J513 only

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Lg. | Each | ||

Short Nuts | |||||||

| A | 3/16" | 0.035" | Brass | 1,900 psi @ 72° F | 5/8" | 000000000 | 00000 |

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 3/4" | 000000000 | 0000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 7/8" | 000000000 | 0000 |

| A | 3/8" | 0.032" | Brass | 1,000 psi @ 72° F | 29/32" | 000000000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1" | 000000000 | 0000 |

| A | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 1" | 000000000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 1/8" | 000000000 | 0000 |

| A | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 1 1/16" | 000000000 | 00000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 5/16" | 000000000 | 00000 |

| A | 3/4" | 0.035" | Brass | 550 psi @ 72° F | 1 5/32" | 000000000 | 00000 |

| A | 3/4" | 0.109" | Brass | 550 psi @ 72° F | 1 1/2" | 000000000 | 00000 |

| B | 1/4" | 0.03" | Brass | 1,400 psi @ 72° F | 5/8" | 00000000 | 0000 |

| B | 1/2" | 0.032" | Brass | 750 psi @ 72° F | 27/32" | 000000000 | 0000 |

| B | 5/8" | 0.035" | Brass | 650 psi @ 72° F | 31/32" | 000000000 | 00000 |

Long Nuts | |||||||

| A | 3/16" | 0.035" | Brass | 1,900 psi @ 72° F | 13/16" | 000000000 | 0000 |

| A | 1/4" | 0.049" | Brass | 1,400 psi @ 72° F | 15/16" | 000000000 | 0000 |

| A | 5/16" | 0.049" | Brass | 1,200 psi @ 72° F | 1 1/8" | 000000000 | 0000 |

| A | 3/8" | 0.065" | Brass | 1,000 psi @ 72° F | 1 5/16" | 000000000 | 0000 |

| A | 1/2" | 0.083" | Brass | 750 psi @ 72° F | 1 5/8" | 000000000 | 00000 |

| A | 5/8" | 0.095" | Brass | 650 psi @ 72° F | 1 7/8" | 000000000 | 00000 |

| A | 3/4" | 0.109" | Brass | 550 psi @ 72° F | 2 3/16" | 000000000 | 00000 |