How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Medium-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

A galvanized finish gives these fittings fair corrosion resistance. They have the strength to handle medium-pressure applications.

Plugs with external hex drive and plugs with round body are also known as bull plugs; the center is hollow, which allows fluid to put pressure on the threads for a tight seal.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASME B31.1, ASME B31.3, ASTM A234, ASTM B633, MSS SP-95, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

| Pipe Size | Plug Construction | Material | Each | |

NPT Male | ||||

|---|---|---|---|---|

| 1/8 | Hollow | Galvanized Steel | 0000000 | 000000 |

| 1/4 | Hollow | Galvanized Steel | 0000000 | 00000 |

| 3/8 | Hollow | Galvanized Steel | 0000000 | 00000 |

| 1 1/4 | Hollow | Galvanized Steel | 0000000 | 00000 |

| 1 1/2 | Hollow | Galvanized Steel | 0000000 | 00000 |

| 2 | Hollow | Galvanized Steel | 0000000 | 000000 |

| 4 | Hollow | Galvanized Steel | 0000000 | 000000 |

Compact Precision Extreme-Pressure Steel Threaded Pipe Fittings

Made to tighter tolerances than other steel pipe fittings, these are also known as instrumentation fittings. They are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are galvanized steel, which has fair corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Water, Hydraulic Fluid

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108

- For Use With: Air, Natural Gas, Water, Hydraulic Fluid

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108

Low-Pressure Press-Connect Steel Unthreaded Pipe Fittings

- For Use On:

EPDM Rubber O-Ring: Ethylene Glycol, Propylene Glycol, Water

Buna-N Rubber O-Ring: Air, Lubricants, Propane, Fuel Oil, Natural Gas, Diesel Fuel - Specifications Met:

EPDM Rubber O-Ring: ASME B31,1, ASME B31.3, ASME B31.9, FM 1920, UL 213

Buna-N Rubber O-Ring: ASME B31.1, ASME B31.3, ASME B31.9, ANSI LC4/CSA 6.32, International Fuel Gas Code - Maximum Pressure:

EPDM Rubber O-Ring: 200 psi @ 72° F

Buna-N Rubber O-Ring: 125 psi @ 72° F - Pipe Nipples and Pipe: Use Schedule 40 Steel

- Flanges: Use Class 150 Steel

Crimp these fittings onto steel pipe to form a tightly sealed connection that’s faster than threading or welding and doesn’t require heat. An internal gripping ring and rubber O-ring create a secure seal when crimped. They are designed to leak if fittings have not been crimped; a colored dot marks the leak path so it's easy to spot unsealed connections. These steel fittings are coated in zinc-nickel to resist corrosion, but will rust if frequently exposed to saltwater or harsh chemicals. They are comparable to Viega MegaPress steel fittings.

Fittings meet ASME B31 code requirements for use in pressure piping systems.

Fittings with an EPDM rubber O-ring are often used for water processing lines, fire sprinklers, and heating and cooling systems. EPDM rubber won’t degrade when exposed to water, ethylene glycol, and propylene glycol. These fittings meet UL 213 and FM 1920 standards for use in fire protection systems.

Buna-N rubber O-rings hold up to natural gas, propane, diesel fuel, lubricants, and other oils. Fittings with these O-rings are often used in fuel gas systems and air lines. They meet the ANSI LC4/CSA 6.32 standard for fuel gas systems and comply with the International Fuel Gas Code.

For technical drawings and 3-D models, click on a part number.

Crimping tools seal fittings in less than five seconds. These tools are cordless, so you can take them to any job. Connect the jaw or ring that matches your pipe size to these tools, then pull the trigger to crimp the fitting. The pivoting head lets you access connections from any angle.

Battery | |||||||

|---|---|---|---|---|---|---|---|

| Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Each | |

| 18V DC | 2 | 3 | Yes | 39 | Viega MegaPress Viega ProPress Viega ProPress XL-C | 00000000 | 000000000 |

Jaw and ring sets include three jaws, three rings, and one ring actuator jaw. Jaws are for pipe sizes 1/2 to 1; they fit directly into the crimping tool. Rings are for pipe sizes 1 1/4 to 2; clip the ring around the fitting and use the ring actuator jaw and crimping tool to press the open ends together.

For Pipe | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Material | For Manufacturer | For Manufacturer Model No. | Compatible With | Includes | Container Type | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | Stainless Steel, Steel | Ridgid | RP 340 | Viega MegaPress | One Ring Actuator Jaw Three Jaws (1/2-1 Pipe Size) Three Rings (1 1/4-2 Pipe Size) | Carrying Case | 00000000 | 000000000 |

Precision Extreme-Pressure Stainless Steel Threaded Pipe Fittings

Made to tighter tolerances than other stainless steel pipe fittings, these are also known as instrumentation fittings. The male threads are rolled for extra strength in extreme-pressure applications. Fittings are commonly used to connect equipment in gas and hydraulic fluid lines. They are 316 stainless steel for excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | |||||

| 1/16 | __ | 7,500 psi @ 72° F | 7,500 psi @ 300° F | 000000000 | 000000 |

| 1/8 | 02 | 6,400 psi @ 72° F | 6,400 psi @ 300° F | 00000000 | 00000 |

| 1/4 | 04 | 6,600 psi @ 72° F | 6,600 psi @ 300° F | 00000000 | 00000 |

| 3/8 | 06 | 5,300 psi @ 72° F | 5,300 psi @ 300° F | 00000000 | 00000 |

| 1/2 | 08 | 5,200 psi @ 72° F | 5,200 psi @ 300° F | 00000000 | 00000 |

| 3/4 | 12 | 4,600 psi @ 72° F | 4,600 psi @ 300° F | 000000000 | 00000 |

| 1 | 16 | 4,400 psi @ 72° F | 4,400 psi @ 300° F | 000000000 | 00000 |

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met:

1/2 Pipe Size: ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A182, ASTM A276, ASTM A479

All other sizes: ASME B1.20.1, ASME B31.1, ASME B31.3

316 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Drive Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Male | ||||||

| 1/16 | __ | 5/32" | 10,000 psi @ 72° F | 10,000 psi @ 300° F | 000000000 | 000000 |

| 1/8 | 02 | 3/16" | 9,100 psi @ 72° F | 9,100 psi @ 300° F | 000000000 | 00000 |

| 1/4 | 04 | 1/4" | 7,500 psi @ 72° F | 7,500 psi @ 300° F | 000000000 | 00000 |

| 3/8 | 06 | 5/16" | 7,200 psi @ 72° F | 7,200 psi @ 300° F | 000000000 | 00000 |

| 1/2 | 08 | 3/8" | 7,700 psi @ 72° F | 7,700 psi @ 300° F | 000000000 | 00000 |

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met:

NPT: ASME B1.20.1, ASME B31.1, ASME B31.3

BSPT: ISO 7-1

316 Stainless Steel | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Dash Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Each | |

NPT Male | ||||||

| 1/16 | __ | Hollow | 10,000 psi @ 72° F | 10,000 psi @ 300° F | 000000000 | 00000 |

| 1/8 | 02 | Solid | 9,700 psi @ 72° F | 9,700 psi @ 300° F | 00000000 | 0000 |

| 1/4 | 04 | Solid | 8,000 psi @ 72° F | 8,000 psi @ 300° F | 00000000 | 00000 |

| 3/8 | 06 | Solid | 7,600 psi @ 72° F | 7,600 psi @ 300° F | 00000000 | 00000 |

| 1/2 | 08 | Solid | 7,000 psi @ 72° F | 7,000 psi @ 300° F | 000000000 | 00000 |

| 3/4 | 12 | Solid | 7,300 psi @ 72° F | 7,300 psi @ 300° F | 000000000 | 00000 |

| 1 | 16 | Solid | 5,300 psi @ 72° F | 5,300 psi @ 300° F | 000000000 | 00000 |

Low-Pressure Press-Connect Stainless Steel Unthreaded Pipe Fittings

- For Use With: Air, Ethylene Glycol, Propylene Glycol, Water, Diesel Fuel, Fuel Oil

- Maximum Pressure: 125 psi @ 72° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- O-Ring Material: Fluoroelastomer Rubber

- Pipe Nipples and Pipe: Use Schedule 10, 40 Stainless Steel

- Flanges: Use Class 150 Stainless Steel

Press these fittings onto stainless steel pipe using a crimping tool for a permanent, leak-tight connection that's faster than threading or welding and doesn't require heat. Fittings have an internal stainless steel gripping ring and rubber O-ring that create a seal when crimped. They are designed to leak if fittings have not been crimped; a colored dot marks the leak path so it's easy to spot unsealed connections. All of these fittings are made of 304 stainless steel to resist corrosion from frequent exposure to water and fuels. They’re often used for water processing lines, heating and cooling systems, and fuel lines. They are comparable to Viega MegaPress fittings.

Fittings meet ANSI/ASME B31 code requirements for use in pressure piping systems.

For technical drawings and 3-D models, click on a part number.

Crimping tools seal fittings in less than five seconds. These tools are cordless, so you can take them to any job. Connect the jaw or ring that matches your pipe size to these tools, then pull the trigger to crimp the fitting. The pivoting head lets you access connections from any angle.

Battery | |||||||

|---|---|---|---|---|---|---|---|

| Voltage | No. Included | Cap., amp-hrs. | Battery Charger Included | Battery Charging Time, min. | Compatible With | Each | |

| 18V DC | 2 | 3 | Yes | 39 | Viega MegaPress Viega ProPress Viega ProPress XL-C | 00000000 | 000000000 |

Jaw and ring sets include three jaws, three rings, and one ring actuator jaw. Jaws are for pipe sizes 1/2 to 1; they fit directly into the crimping tool. Rings are for pipe sizes 1 1/4 to 2; clip the ring around the fitting and use the ring actuator jaw and crimping tool to press the open ends together.

For Pipe | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Material | For Manufacturer | For Manufacturer Model No. | Compatible With | Includes | Container Type | Each | |

| 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | Stainless Steel, Steel | Ridgid | RP 340 | Viega MegaPress | One Ring Actuator Jaw Three Jaws (1/2-1 Pipe Size) Three Rings (1 1/4-2 Pipe Size) | Carrying Case | 00000000 | 000000000 |

Precision Extreme-Pressure Brass Threaded Pipe Fittings

Also known as instrumentation fittings, these have the most precise threads and the tightest tolerances of all the brass pipe fittings we offer. Fittings are brass for good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Argon, Natural Gas, Nitrogen Gas, Oil, Oxygen, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

- For Use With: Air, Argon, Natural Gas, Nitrogen Gas, Oil, Oxygen, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

- For Use With: Air, Argon, Natural Gas, Nitrogen Gas, Oil, Oxygen, Steam, Water

- Specifications Met:

NPT: ASME B1.20.1, ASME B31.1, ASME B31.3

BSPT: ASME B31.3, DIN 2999, ISO 7.1

| Pipe Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Each | |

NPT Male | |||||

|---|---|---|---|---|---|

| 1/8 | Hollow | 5,600 psi @ 72° F | 1,500 psi @ 300° F | 0000000 | 00000 |

| 1/4 | Hollow | 4,100 psi @ 72° F | 1,500 psi @ 300° F | 0000000 | 0000 |

| 3/8 | Hollow | 4,000 psi @ 72° F | 1,500 psi @ 300° F | 0000000 | 00000 |

| 1/2 | Hollow | 3,900 psi @ 72° F | 1,500 psi @ 300° F | 0000000 | 00000 |

| 3/4 | Hollow | 3,800 psi @ 72° F | 1,500 psi @ 300° F | 0000000 | 00000 |

Aluminum Quick-Connect Pipe Fittings for Compressed Air

Twist these fittings onto aluminum pipe for quick, sealed connections—no threading, soldering, or welding necessary. Use them to build a compressed air system in half the time it would take to build a copper or steel system. Also known as Unipipe fittings, they’re part of a quick-connect system that’s compatible with pipe from Unipipe, Transair, and Infinity.

Finger tighten the collar on the end of these fittings, then use a wrench for the final quarter turn. The inside of these fittings has a compression ring and O-ring to seal against the pipe. They’re easy to take apart as needed to modify your setup.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Coolant, Nitrogen, Oil

- Temperature Range: 0° to 210° F

- Specifications Met: ASME B31.1, ASME B31.3, ASME B31.9

- Pipe Nipples and Pipe: Use Quick-Disconnect Aluminum

Plugs block the end of a fitting. They include a ¼ BSPP valve that can be used to exhaust your line or attach a pressure gauge. To install, remove the fitting's nut, collar, and grip ring. Insert the plug into the fitting, slide the collar on, and tighten the nut. Discard the connector's grip ring.

Press-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Maximum Pressure: 200psi @ 72° F

- Temperature Range: 0° to 250° F

- Tubing: Use with K, M, L copper

- Specifications Met: See table

Crimp these fittings to copper tubing with a crimping tool (sold separately). An O-ring on the inside of the fitting creates a leak-tight connection that doesn’t require heat or soldering. They are comparable to Viega ProPress fittings. Fittings have good corrosion resistance. They meet NSF/ANSI safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

For technical drawings and 3-D models, click on a part number.

| Copper Tube Size | For Tube OD | Lg. | Material | Specifications Met | Each | |

| 1 1/4 | 1 3/8" | 1 5/16" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

| 1 1/2 | 1 5/8" | 1 5/8" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 00000 |

| 2 | 2 1/8" | 1 13/16" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 00000 |

| 2 1/2 | 2 5/8" | 2 7/64" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

| 3 | 3 1/8" | 2 23/64" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

| 4 | 4 1/8" | 2 49/64" | Copper | ASME B16.51, ASME B31.1, ASME B31.3, ASME B31.9, NSF/ANSI 61, UL 213 | 00000000 | 000000 |

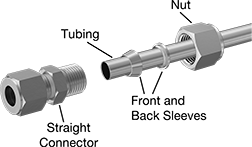

Yor-Lok Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: See table

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. Fittings are zinc-plated steel for fair corrosion resistance. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

For technical drawings and 3-D models, click on a part number.

Caps for fittings replace the nut and sleeve of an existing fitting.

For Tube | Caps For Fitting | ||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1" | 0.065" | Zinc-Plated Steel | 2,100 psi @ 72° F | -20° to 395° | ASME B1.20.1, ASME B31.1, ASME B31.3, ASTM A108 | 00000000 | 000000 |

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1" | 0.065" | Zinc-Plated Steel | 2,100 psi @ 72° F | -20° to 395° | ASTM A108 | 00000000 | 000000 |

For Tube | ||||||||

|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Front Sleeve Material | Back Sleeve Material | Max. Pressure | Temp. Range, °F | Specifications Met | Each | |

| 1" | 0.065" | Zinc-Plated Steel | 316 Stainless Steel | 2,100 psi @ 72° F | -20° to 800° | ASME B31.3 | 00000000 | 000000 |