How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

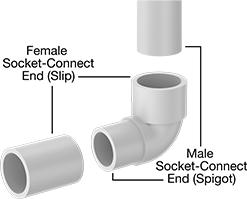

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 14, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Gravity-Flow CPVC Pipe Fittings for Corrosive Chemical Waste

- For Use With: Hydrochloric Acid, Nitric Acid, Salt Water, Sulfuric Acid

- Temperature Range: 40° to 200° F

- Specifications Met: ASTM F2618, IAPMO Listed, NSF/ANSI 14, UL 94 V-0

Made of CPVC, these fittings have better chemical resistance than ABS plastic gravity-flow fittings and can stand up to highly-corrosive acids and other harsh substances. They meet NSF/ANSI 14 requirements for use in corrosive waste gravity-flow systems. Fittings are comparable to Corzan. They meet UL 94 V-0 for flame retardance and ASTM F2618 specifications and testing requirements for material quality. They are IAPMO certified to comply with the International Association for Plumbing and Mechanical Officials product performance standards and the Uniform Plumbing Code (UPC) for installation and repair of plumbing systems.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

270° bend fittings are also known as P-traps. They separate into three pieces, so you can access your line.

Offset tees are also known as sanitary tees and eccentric tees. They have an offset branch so the line can drain. Use them for applications that require frequent cleaning and inspecting.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

Gravity-Flow CPVC Pipe for Corrosive Chemical Waste

- For Use With: Hydrochloric Acid, Nitric Acid, Salt Water, Sulfuric Acid

- Temperature Range: 40° to 200° F

- Specifications Met: ASTM F2618, IAPMO Listed, NSF/ANSI 14, UL 94 V-0

Use this pipe in gravity-flow applications that involve highly-corrosive chemicals–it meets NSF/ANSI 14 requirements for use in corrosive waste systems. Pipe is made of CPVC, which has better chemical resistance than ABS plastic to stand up to acids and other harsh substances. Connect to unthreaded female socket-connect fittings using a CPVC primer and cement (also known as solvent weld). Pipe is comparable to Corzan. It meets UL 94 V-0 for flame retardance and ASTM F2618 specifications and testing requirements for material quality. It is IAPMO certified to comply with the International Association for Plumbing and Mechanical Officials product performance standards and the Uniform Plumbing Code (UPC) for installation and repair of plumbing systems.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

| Pipe Size | OD | ID | Wall Thick. | Material | Color | Each | |

2 ft. | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/2 | 1 29/32" | 1.61" | 0.145" | CPVC Plastic | Light Gray | 0000000 | 000000 |

| 2 | 2 3/8" | 2.067" | 0.154" | CPVC Plastic | Light Gray | 0000000 | 00000 |

4 ft. | |||||||

| 1 1/2 | 1 29/32" | 1.61" | 0.145" | CPVC Plastic | Light Gray | 0000000 | 00000 |

| 2 | 2 3/8" | 2.067" | 0.154" | CPVC Plastic | Light Gray | 0000000 | 000000 |

8 ft. | |||||||

| 1 1/2 | 1 29/32" | 1.61" | 0.145" | CPVC Plastic | Light Gray | 0000000 | 000000 |

| 2 | 2 3/8" | 2.067" | 0.154" | CPVC Plastic | Light Gray | 0000000 | 000000 |

| Pipe Cement (16 fl. oz. Can) | 0000000 | Each | 000000 |

Socket-Connect Fittings for Plastic Tubing—Drinking Water

- Temperature Range: 40° to 180° F

- Tubing: Use with hard CPVC plastic

- Specifications Met: ASTM D2846, National Standard Plumbing Code, NSF/ANSI 61, NSF/ANSI 372, UPC Compliant, NSF/ANSI 14

Slide CPVC tubing into the socket end of these fittings and seal with cement for a permanent connection. They are also known as solvent-weld fittings and CTS (Copper Tube Size) fittings.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.