How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

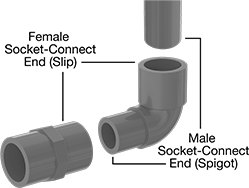

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

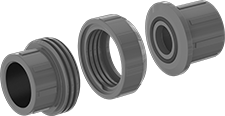

Unions separate into three pieces so you can access your line.

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493, ISO 7-1

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

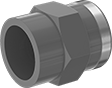

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| DIN Size, mm | Socket Depth, mm | Pipe Size | Collar Material | Material | Color | Max. Pressure | Each | |

BSPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 20 | 16 | 1/2 | Stainless Steel | CPVC Plastic | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

| 25 | 19 | 3/4 | Stainless Steel | CPVC Plastic | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 32 | 22 | 1 | Stainless Steel | CPVC Plastic | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 50 | 31 | 1 1/2 | Stainless Steel | CPVC Plastic | Light Gray | 230 psi @ 72° F | 00000000 | 00000 |

| 63 | 38 | 2 | Stainless Steel | CPVC Plastic | Light Gray | 230 psi @ 72° F | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493, ISO 7-1

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493, ISO 7-1

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Unions separate into three pieces so you can access your line.

DIN Metric Female Socket Connection | Female Socket Connection | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| DIN Size, mm | Socket Depth, mm | Pipe Size | Socket Depth, mm | Material | O-Ring Material | Color | Max. Pressure | Each | |

| 16 | 14 | 3/8 | 19 | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72 ° F | 00000000 | 000000 |

| 20 | 16 | 1/2 | 20 | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72 ° F | 00000000 | 00000 |

| 40 | 26 | 1 1/4 | 32 | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72 ° F | 00000000 | 000000 |

| 63 | 37 | 2 | 38 | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72 ° F | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Citric Acid, Formic Acid (25%), Hydrochloric Acid (30%), Nitric Acid (65%), Sulfuric Acid (95%), Water

- Maximum Temperature: 170° F

- Specifications Met: ISO 15493

- Pipe Nipples and Pipe: Use CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

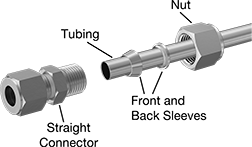

Ultra-Corrosion-Resistant Yor-Lok Fittings for Nickel Alloy Tubing

- For Use With: Acetic Acid, Air, Bleach, Cutting Oil, Diesel Fuel, Formic Acid, Fuel Oil, Gasoline, Hydraulic Fluid, Iron Chlorides, Mineral Oil, Salt Water, Steam, Water

- Temperature Range: 0° to 1000° F

- Tubing: Use with seamless soft C276 nickel

- Specifications Met: ASME B31.3

With the best corrosion resistance of any metal tube fittings we offer, these C276 nickel Hastelloy fittings stand up to aggressive chemicals and resist pitting and cracking from stress. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They include a nut with two sleeves (ferrules). The sleeves bite into tubing as you tighten the nut, creating a strong, leak-resistant seal. Fittings are compatible with Swagelok®, Let-Lok, and A-Lok fittings.