How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

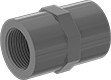

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

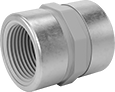

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| Pipe Size | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 000000 |

| 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

- For Use With:

Fittings with Neoprene Rubber Gaskets: Drinking Water, Water

All other fittings: Acetic Acid (10%), Calcium Chloride, Deionized Water, Hydrochloric Acid (25%), Phosphoric Acid, Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water - Maximum Temperature:

Fittings with Neoprene Rubber Gaskets: 200° F

All other fittings: 180° F - Specifications Met:

Fittings with Neoprene Rubber Gaskets: ASTM D1784, NSF/ANSI 61

All other fittings: ASTM D1784 - Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

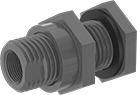

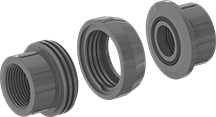

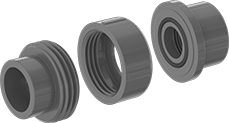

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall, tank, or panel to create an inlet or outlet for faucets, pipes, and spigots.

| Pipe Size | For Hole Dia. | For Max. Wall Thick. | Material | Gasket Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 1 1/16" | 1/2" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3/8 | 1 3/16" | 1/2" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 1 3/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1/2 | 1 1/2" | 3/4" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 1 5/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1 3/4" | 3/4" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 1 | 1 7/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 | 2" | 13/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 1 1/4 | 2 3/8" | 13/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

| 1 1/4 | 2 21/32" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 2 5/8" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 2 3/4" | 13/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

| 2 | 3 1/4" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 2 | 3 3/8" | 1 3/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

| 3 | 4 1/2" | 2 1/8" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 4 | 5 1/2" | 1 1/4" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 4 | 5 3/4" | 3 1/4" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

- For Use With:

Fittings with EPDM Rubber O-Rings: Drinking Water, Water

All other fittings: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water - Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

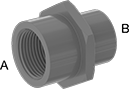

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | O-Ring Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3/4 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 4 | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

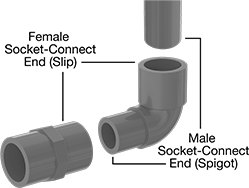

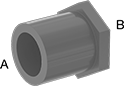

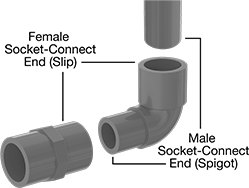

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Socket Depth | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 11/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | 3/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 3/4 | 1" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | 1 1/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | 1 9/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | 1 3/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3 | 1 29/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 4 | 2 1/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 6 | 3" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| Pipe Size | Socket Depth | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 7/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 0000 |

| 1 | 1 1/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 1/4" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 310 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| 2 1/2 | 1 3/4" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 250 psi @ 72° F | 00000000 | 00000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Socket Depth | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | 15/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3/4 | 1" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | 1 1/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 1/4 | 1 1/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | 1 25/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3 | 1 29/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 4 | 2 5/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 6 | 3" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | OD | ID | Wall Thick. | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 27/32" | 0.546" | 0.147" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/4 | 1 3/64" | 0.742" | 0.154" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 | 1 5/16" | 0.957" | 0.179" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/4 | 1 21/32" | 1.278" | 0.191" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 1.939" | 0.218" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

- For Use With:

Fittings with Neoprene Rubber Gaskets: Drinking Water, Water

All other fittings: Acetic Acid (10%), Calcium Chloride, Deionized Water, Hydrochloric Acid (25%), Phosphoric Acid, Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water - Maximum Temperature:

Fittings with Neoprene Rubber Gasket: 200° F

All other fittings: 180° F - Specifications Met:

Fittings with Neoprene Rubber Gaskets: ASTM D1784, NSF/ANSI 61

All other fittings: ASTM D1784 - Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall, tank, or panel to create an inlet or outlet for faucets, pipes, and spigots.

| Pipe Size | Socket Depth | For Hole Dia. | For Max. Wall Thick. | Material | Gasket Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 5/8" | 1 1/16" | 1/2" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3/8 | 3/4" | 1 3/16" | 1/2" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 7/8" | 1 1/2" | 3/4" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 29/32" | 1 3/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 1" | 1 3/4" | 3/4" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 1 1/64" | 1 5/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 | 1 1/8" | 2" | 13/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 1 | 1 9/64" | 1 7/8" | 2 1/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 1/4 | 1 17/64" | 2 5/8" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 1 17/64" | 2 5/8" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 1 1/2 | 1 3/8" | 2 3/4" | 13/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 00000 |

| 2 | 1 25/64" | 3 1/4" | 2" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 00000 |

| 2 | 1 1/2" | 3 3/8" | 1 3/16" | CPVC Plastic | Neoprene Rubber | Light Gray | 150 psi @ 72° F | 0000000 | 000000 |

| 3 | 1 57/64" | 4 1/2" | 2 1/8" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 000000 |

| 4 | 2 17/64" | 5 3/4" | 2 7/16" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 000000 |

| 6 | 3 1/32" | 8 1/16" | 3 1/4" | CPVC Plastic | EPDM Rubber | Light Gray | 150 psi @ 72° F | 000000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | O-Ring Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 7/8" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3/4 | 1" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 1 1/8" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/4 | 1 1/4" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 1/2 | 1 3/4" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | 1 7/8" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 4 | 2 1/4" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

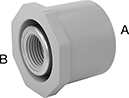

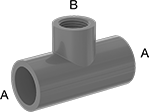

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

(A) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size (B) | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

| 1/2 | 7/8" | 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1" | 1/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 0000 |

| 3/4 | 1" | 1 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

(A) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size (B) | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||||

| 3/8 | 43/64" | 0.423" | 0.126" | 1/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1/2 | 27/32" | 0.546" | 0.147" | 1/8 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 500 psi @ 72° F | 00000000 | 0000 |

| 1/2 | 27/32" | 0.546" | 0.147" | 1/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1/2 | 27/32" | 0.546" | 0.147" | 3/8 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 3/4 | 1 3/64" | 0.742" | 0.154" | 1/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 3/4 | 1 3/64" | 0.742" | 0.154" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 3/4 | 1 1/8" | 0.848" | 0.265" | 3/8 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 0000 |

| 1 | 1 5/16" | 0.902" | 0.179" | 3/8 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 1 5/16" | 0.957" | 0.179" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 | 1 5/16" | 0.957" | 0.179" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 1/4 | 1 5/8" | 1.255" | 0.27" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 5/8" | 1.255" | 0.27" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 21/32" | 1.278" | 0.191" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 29/32" | 1.5" | 0.2" | 1 1/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 0.674" | 0.218" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 1.939" | 0.218" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 1.939" | 0.218" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 1.939" | 0.218" | 1 1/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 3/8" | 1.939" | 0.218" | 1 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 1/2 | 2 7/8" | 2.297" | 0.276" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 1/2 | 2 7/8" | 2.323" | 0.276" | 1 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 3 1/2" | 2.85" | 0.3" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | 3 1/2" | 2.864" | 0.3" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | 3 1/2" | 2.869" | 0.631" | 2 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 3 | 3 1/2" | 2.875" | 0.3" | 1 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 4 | 4 1/2" | 3.817" | 0.337" | 3 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 4 | 4 1/2" | 3.826" | 0.337" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 6 | 6 5/8" | 5.715" | 0.432" | 4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

(A) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size (B) | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||||

| 1 1/2 | 1 7/8" | 1.913" | 0.218" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 1 7/8" | 1.913" | 0.218" | 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 3/8" | 2.29" | 0.276" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 3/8" | 2.29" | 0.276" | 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| 2 | 2 3/8" | 2.29" | 0.276" | 1 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

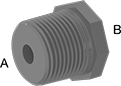

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size (A) | Pipe Size (B) | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 1/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3/8 | 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1/2 | 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/4 | 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/4 | 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/4 | 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 1/4 | 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 2 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 6 | 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| Pipe Size | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 00000 |

| 3/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Socket Depth | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 5/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/8 | 25/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1/2 | 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 3/4 | 1" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 | 1 5/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/4 | 1 13/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 1 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | 2 1/4" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| Pipe Size | Socket Depth | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 7/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

| 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

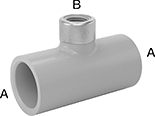

Inline tees are also known as branch tees.

| Pipe Size | Socket Depth | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 5/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 1/2 | 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/4 | 1" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 1 1/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/4 | 1 9/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 7/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 17/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 1 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | 2 9/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Inline tees are also known as branch tees.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

| Pipe Size | Socket Depth | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 7/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 2 | 1 1/2" | CPVC Plastic | Stainless Steel | 80 | Light Gray | 240 psi @ 72° F | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Inline tees are also known as branch tees.

(A) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size (B) | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

| 3/4 | 1" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 1 | 1 1/8" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 | 1 1/8" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/4 | 1 1/4" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 1 13/32" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 1 1/2" | 1 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 1 7/8" | 1 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | 1 7/8" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 3 | 1.88" | 1/2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3 | 1.88" | 3/4 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 4 | 2 1/4" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Inline tees are also known as branch tees.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

(A) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size (B) | Material | Collar Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||

| 1/2 | 7/8" | 1/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 510 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 1" | 1/4 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 410 psi @ 72° F | 00000000 | 00000 |

| 1 | 1 1/8" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 370 psi @ 72° F | 00000000 | 00000 |

| 1 1/4 | 1 1/4" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 310 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | 1/2 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 1 3/8" | 1 | CPVC Plastic | Stainless Steel | 80 | Light Gray | 280 psi @ 72° F | 00000000 | 00000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Saddle-tap tees allow you to create additional outlets and connections in metal or plastic pipe. They clamp on for an easy way to install and maintain systems.

| Pipe Size | For Pipe Size | For Pipe OD | For Hole Dia. | Material | Schedule | Color | Max. Pressure | Washer Material | Each | |

NPT Threads | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 2 | 2 3/8" | 3/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 1/2 | 3 | 3 1/2" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 1/2 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 3/4 | 2 | 2 3/8" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 3/4 | 3 | 3 1/2" | 7/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 3/4 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 1 | 2 | 2 3/8" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 1 | 3 | 3 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 1 | 4 | 4 1/2" | 1 1/8" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 1 1/2 | 3 | 3 1/2" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 00000 |

| 1 1/2 | 4 | 4 1/2" | 1 3/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 2 | 4 | 4 1/2" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 230 psi @ 72° F | Zinc | 00000000 | 000000 |

| 2 | 6 | 6 5/8" | 2 1/4" | CPVC Plastic | 80 | Light Gray | 200 psi @ 72° F | Zinc | 00000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

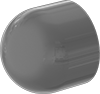

| Pipe Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3/8 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 3/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 0000 |

| 1 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 1 1/2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 2 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 3 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 00000 |

| 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 0000000 | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

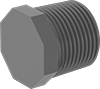

| Pipe Size | Drive Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/4 | 21/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3/8 | 13/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1/2 | 15/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 3/4 | 1 3/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 | 1 9/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000 |

| 1 1/4 | 1 25/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 1 1/2 | 2 1/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 | 2 7/16" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 2 1/2 | 3 1/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 3 | 3 23/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 4 | 4 23/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| 6 | 6 7/8" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

CPVC Pipe for Hot Water

Made of CPVC, this pipe can withstand high temperatures up to 170° or 200° F. It meets NSF/ANSI Standard 61 for drinking water. Also known as Schedule 80 pipe, it has thick, strong walls for use in heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. Pipe has good corrosion resistance. It is comparable to Corzan.

Connect unthreaded pipe to unthreaded female socket-connect fittings using a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

ASTM D1784 pipe meets specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Fittings: Use Schedule 80 CPVC plastic

- Flanges: Use Class 150 CPVC plastic

| Pipe Size | Lg. | OD | ID | Wall Thick. | Color | Max. Pressure | Each | |

NPT Threads | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 | 7/8" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 00000 |

| 3/8 | 1" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 1/2 | 1 1/8" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 3/4 | 1 3/8" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 1 | 1 1/2" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 0000 |

| 1 1/4 | 1 5/8" | 1 21/32" | 1.278" | 0.191" | Light Gray | 260 psi @ 72° F | 0000000 | 0000 |

| 1 1/2 | 1 3/4" | 1 29/32" | 1.5" | 0.2" | Light Gray | 235 psi @ 72° F | 0000000 | 0000 |

| 2 | 2" | 2 3/8" | 1.939" | 0.218" | Light Gray | 200 psi @ 72° F | 0000000 | 0000 |

| 2 1/2 | 2 1/2" | 2 7/8" | 2.323" | 0.276" | Light Gray | 210 psi @ 72° F | 0000000 | 00000 |

| 3 | 2 5/8" | 3 1/2" | 2.9" | 0.3" | Light Gray | 185 psi @ 72° F | 0000000 | 00000 |

| 4 | 2 7/8" | 4 1/2" | 3.826" | 0.337" | Light Gray | 160 psi @ 72° F | 0000000 | 00000 |

| Non-Hardening Thread Sealant | 000000 | Each | 000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Fittings: Use Schedule 80 CPVC plastic

- Flanges: Use Class 150 CPVC plastic

| Lg. | OD | ID | Wall Thick. | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

1/4 Pipe Size | |||||||

| 1 1/2" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 00000 |

| 2" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 2 1/2" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 0000 |

| 3" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 4" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 5" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 0000 |

| 6" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 8" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 10" | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 0000 |

| 1 ft. | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 0000000 | 00000 |

| 2 ft. | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 00000 |

| 3 ft. | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 00000 |

| 5 ft. | 35/64" | 0.302" | 0.119" | Light Gray | 565 psi @ 72° F | 00000000 | 00000 |

3/8 Pipe Size | |||||||

| 1 1/2" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 2" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 2 1/2" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 00000000 | 0000 |

| 3" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 4" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 5" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 00000000 | 0000 |

| 6" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 8" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 0000 |

| 10" | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 00000 |

| 1 ft. | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 0000000 | 00000 |

| 2 ft. | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 00000000 | 00000 |

| 3 ft. | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 00000000 | 00000 |

| 5 ft. | 43/64" | 0.423" | 0.126" | Light Gray | 460 psi @ 72° F | 00000000 | 00000 |

1/2 Pipe Size | |||||||

| 1 1/2" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 2" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 2 1/2" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 00000000 | 0000 |

| 3" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 4" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 5" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 00000000 | 0000 |

| 6" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 8" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 10" | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 0000 |

| 1 ft. | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 0000000 | 00000 |

| 2 ft. | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 00000000 | 00000 |

| 3 ft. | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 00000000 | 00000 |

| 5 ft. | 27/32" | 0.546" | 0.147" | Light Gray | 420 psi @ 72° F | 00000000 | 00000 |

3/4 Pipe Size | |||||||

| 1 1/2" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 0000 |

| 2" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 2 1/2" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 0000 |

| 3" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 4" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 5" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 0000 |

| 6" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 8" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 0000 |

| 10" | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 00000 |

| 1 ft. | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 0000000 | 00000 |

| 2 ft. | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 00000 |

| 3 ft. | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 00000 |

| 5 ft. | 1 3/64" | 0.742" | 0.154" | Light Gray | 340 psi @ 72° F | 00000000 | 00000 |

1 Pipe Size | |||||||

| 2" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 0000 |

| 2 1/2" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 00000000 | 0000 |

| 3" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 0000 |

| 4" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 0000 |

| 5" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 00000000 | 0000 |

| 6" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 0000 |

| 8" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 00000 |

| 10" | 1 5/16" | 0.957" | 0.179" | Light Gray | 315 psi @ 72° F | 0000000 | 00000 |