How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

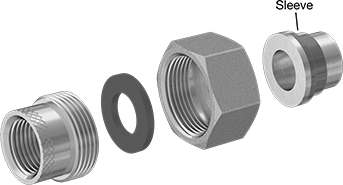

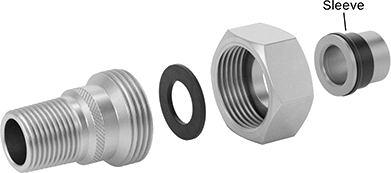

Medium-Pressure Pipe Fittings for Joining Dissimilar Metals

Use these unions to connect different metals in a piping or plumbing system. They have a plastic sleeve that inhibits destructive corrosion. Use them for connections that must be electrically insulated. Unions separate into three pieces for access to your line.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Air, Water, Oil, Natural Gas

- Max.Temperature: 180° F

Iron × Copper | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Lg. | Copper Tube Size | For Tube OD | Max. Pressure | Each | |

NPT Female × Socket Connect Female | ||||||

| 1/2 | 1 7/8" | 1/2 | 5/8" | 250 psi @ 72° F | 000000 | 000000 |

| 1/2 | 1 7/8" | 3/8 | 1/2" | 250 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 1 7/8" | 1/2 | 5/8" | 250 psi @ 72° F | 000000 | 00000 |

| 3/4 | 2 1/8" | 3/4 | 7/8" | 250 psi @ 72° F | 000000 | 00000 |

| 1 | 2 1/2" | 1 | 1 1/8" | 250 psi @ 72° F | 000000 | 00000 |

| 1 | 2 1/2" | 3/4 | 7/8" | 250 psi @ 72° F | 000000 | 00000 |

| 1 1/4 | 3" | 1 1/4 | 1 3/8" | 250 psi @ 72° F | 000000 | 00000 |

| 1 1/2 | 3" | 1 1/2 | 1 5/8" | 250 psi @ 72° F | 000000 | 00000 |

| 2 | 3" | 2 | 2 1/8" | 250 psi @ 72° F | 000000 | 000000 |

NPT Male × Socket Connect Female | ||||||

| 1/2 | 2 5/8" | 1/2 | 5/8" | 250 psi @ 72° F | 00000000 | 00000 |

| 1/2 | 3" | 3/8 | 1/2" | 250 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 2 15/16" | 3/4 | 7/8" | 250 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 3" | 1/2 | 5/8" | 250 psi @ 72° F | 00000000 | 00000 |

| 3/4 | 3" | 3/4 | 7/8" | 250 psi @ 72° F | 00000000 | 00000 |

Solder-Connect Fittings for Copper Tubing

- Temperature Range: 32° to 200° F

Solder these fittings to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. To adhere to safety standards for drinking water systems, use fittings that meet NSF/ANSI 61 or EN 1057.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

- For Use With: Drinking Water

- Tubing: Use with K, M, L copper

- Specifications Met: See table

Union connectors separate into three pieces for easy access to your line.

| Copper Tube Size | For Tube OD | Material | Max. Pressure | Specifications Met | Each | |

| 1/4 | 3/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 00000000 | 000000 |

| 3/8 | 1/2" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

| 1/2 | 5/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 0000 |

| 3/4 | 7/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 0000 |

| 1 | 1 1/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

| 1 1/4 | 1 3/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

| 1 1/2 | 1 5/8" | Copper | 400 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

| 2 | 2 1/8" | Copper | 300 psi @ 72° F | ASME B16.22, MSS-SP104, NSF/ANSI 61 | 0000000 | 00000 |

Cleaned and Bagged Solder-Connect Fittings for Copper Tubing

- For Use With: Drinking Water

- Temperature Range: 32° to 200° F

- Tubing: Use with K, M, L copper

- Specifications Met: ASME B16.22, MSS-SP104, NSF/ANSI 61

When cleanliness is crucial to your application, choose these fittings that are individually cleaned and bagged to prevent contamination. Solder the socket end to copper tubing or the tube end of another fitting for a permanent, leak-tight connection. They are also known as sweat fittings. Fittings have good corrosion resistance. They meet NSF/ANSI 61 safety standards for use with drinking water systems.

Copper tube size is the accepted designation of the copper tubing industry, not the actual tube OD.

Union connectors separate into three pieces for easy access to your line.

| Copper Tube Size | For Tube OD | Material | Max. Pressure | Each | |

| 1/4 | 3/8" | Copper | 400 psi @ 72° F | 0000000 | 000000 |

| 3/8 | 1/2" | Copper | 400 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 5/8" | Copper | 400 psi @ 72° F | 0000000 | 00000 |

| 3/4 | 7/8" | Copper | 400 psi @ 72° F | 0000000 | 00000 |

| 1 | 1 1/8" | Copper | 400 psi @ 72° F | 0000000 | 00000 |

| 1 1/2 | 1 5/8" | Copper | 400 psi @ 72° F | 0000000 | 00000 |

| 2 | 2 1/8" | Copper | 400 psi @ 72° F | 0000000 | 00000 |