How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

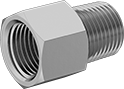

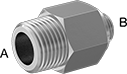

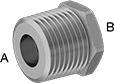

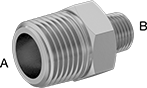

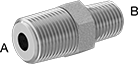

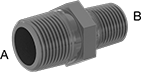

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line. 304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Specifications Met:

BSPP × NPT and 316 Stainless Steel BSPT × NPT: ASTM A351

304 Stainless Steel BSPT × NPT: ASME B1.20.1, DIN EN 10226 - Fabrication: Heat Treated

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Pipe Size | 304 Stainless Steel | 316 Stainless Steel | |||||

|---|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Max. Steam Pressure | Each | Each | ||

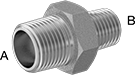

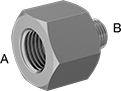

BSPP Male × NPT Male | |||||||

| 1/4 | 1/8 | 300 psi @ 72° F | 150 psi @ 350° F | 000000 | 00 | 00000000 | 00000 |

| 3/8 | 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 000000 | 00000000 | 00000 |

| 1/2 | 1/8 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/2 | 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 00000 | 00000000 | 00000 |

BSPT Male × NPT Male | |||||||

| 1/4 | 1/8 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 0000 | 00000000 | 0000 |

| 3/8 | 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | 000000 | 00 | 00000000 | 00000 |

| 1/2 | 1/8 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 00000 | 00000000 | 00000 |

| 1/2 | 1/4 | 300 psi @ 72° F | 150 psi @ 350° F | 00000000 | 00000 | 00000000 | 00000 |

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Fabrication: Heat Treated

- Specifications Met:

NPT: ASTM A351

BSPT: DIN EN 10226 - Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

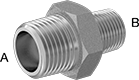

High-Pressure Stainless Steel Threaded Pipe Fittings

Use these heavy duty fittings in high-pressure flow applications.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

- For Use With:

NPT Threads: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

BSPT/BSPP Threads: Air, Coolant, Diesel Fuel, Hydraulic Fluid, Natural Gas, Oil, Steam, Water - Pressure Class: See table

- Specifications Met:

NPT Threads: ASTM A182

BSPT/BSPP Threads: NSF/ANSI 169 - Pipe Nipples and Pipe: Use Schedule 80 stainless steel

- Temperature Range: See table

Pipe Size | Dash Size | |||||||

|---|---|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Pressure Class | Max. Pressure | Max. Steam Pressure | Each | |

304 Stainless Steel | ||||||||

NPT Male × NPT Female | ||||||||

| 2 | 3/8 | 32 | 06 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 000000 |

| 2 | 1/2 | 32 | 08 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 00000 |

| 2 | 3/4 | 32 | 12 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 00000 |

| 2 | 1 | 32 | 16 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 00000 |

| 2 | 1 1/4 | 32 | 20 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 00000 |

| 2 | 1 1/2 | 32 | 24 | 3000 | 2,500 psi @ 72° F | 1,900 psi @ 350° F | 00000000 | 00000 |

316 Stainless Steel | ||||||||

NPT Male × NPT Female | ||||||||

| 2 | 3/8 | 32 | 06 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

| 2 | 1/2 | 32 | 08 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

| 2 | 3/4 | 32 | 12 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

| 2 | 1 | 32 | 16 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

| 2 | 1 1/4 | 32 | 20 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

| 2 | 1 1/2 | 32 | 24 | 3000 | 3,000 psi @ 72° F | 2,800 psi @ 350° F | 00000000 | 000000 |

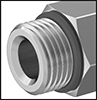

Medium-Pressure Stainless Steel Threaded Pipe Fittings

Choose these fittings when you want the same high-quality found in our low-pressure pipe fittings, but need more strength to handle higher pressures.

316 stainless steel fittings have excellent corrosion resistance.

BSPP male threads have a gasket to protect against leaks.

Fluoroelastomer gaskets withstand high and low temperatures like silicone gaskets do, and also have some resistance to fuel and oil.

- For Use With: Air, Coolant, Natural Gas, Oil, Steam, Water

- Pressure Class : 150

- Specifications Met: ASTM A314, ASTM A320, ASTM A582

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Pipe Size | 316 Stainless Steel | |||||

|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Max. Steam Pressure | Gasket Material | Each | |

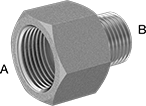

NPT Female × BSPP Male | ||||||

| 1/2 | 1/8 | 500 psi @ 72° F | 100 psi @ 350° F | Fluoroelastomer Rubber | 00000000 | 000000 |

Precision Extreme-Pressure Stainless Steel Threaded Pipe Fittings

Made to tighter tolerances than other stainless steel pipe fittings, these are also known as instrumentation fittings. The male threads are rolled for extra strength in extreme-pressure applications. Fittings are commonly used to connect equipment in gas and hydraulic fluid lines. They are 316 stainless steel for excellent corrosion resistance.

- For Use With: Hydraulic Fluid, Liquid Nitrogen, Natural Gas, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

316 Stainless Steel | |||||

|---|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | |||||

| 1/2 | 08 | 5,200 psi @ 72° F | 5,200 psi @ 300° F | 00000000 | 000000 |

Extreme-Pressure Stainless Steel Threaded Pipe Fittings

With the strength to handle extreme pressures, these fittings can be used to connect equipment in hydraulic fluid lines. 316 stainless steel fittings have excellent corrosion resistance.

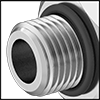

NPTF (Dryseal) threads are compatible with NPT threads. BSPP and metric male threads have either a gasket or a gasket and washer to prevent leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have a gasket to prevent leaks.

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met: See table

316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | For Use With | Specifications Met | Each | |

NPTF Male × UN/UNF (SAE Straight) Male | ||||||||

| 3/8 | 06 | 9/16"-18 | 06 | 6,000 psi @ 72° F | Hydraulic Fluid (Petroleum Base), Oil, Water | SAE J514 | 000000000 | 000000 |

Threads with

Gasket and Washer

- For Use With: Hydraulic Fluid, Oil, Water

- Specifications Met:

NPT × BSPP and BSPP × NPT: ASME B1.20.3, ISO 1179, ISO 8434-6

BSPP × BSPT and BSPT × BSPP: DIN EN 10226, ISO 1179, ISO 7.1, ISO 8434-6

Pipe Size | Dash Size | 316 Stainless Steel | ||||

|---|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Max. Pressure | Each | |

BSPP Male × NPT Male | ||||||

| 3/8 | 1/4 | 06 | 04 | 5,500 psi @ 72° F | 00000000 | 000000 |

- For Use With: Hydraulic Fluid, Oil, Water

- Specifications Met:

BSPP: ISO 1179, ISO 8434-6

316 Stainless Steel | ||||

|---|---|---|---|---|

| Pipe Size | Dash Size | Max. Pressure | Each | |

NPTF Female | ||||

| 1/2 | 08 | 6,000 psi @ 72° F | 000000000 | 000000 |

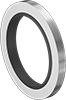

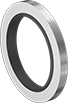

- Temperature Range: -22° to 230° F

316 Stainless Steel | ||||

|---|---|---|---|---|

| For Pipe Size | Gasket Material | Thickness | Each | |

For BSPP Male | ||||

| 3/8 | Buna-N Rubber | 2mm | 00000000 | 00000 |

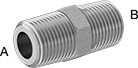

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance. Fittings rated for use with drinking water meet NSF/ANSI 61 safety standards.

- For Use With:

Brass: Air, Drinking Water, Natural Gas, Oil

Bronze: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges: See table

Pipe Size | For Flange | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Body Shape | Material | Hex Width | Class | Material | Specifications Met | Each | |

NPT Male × NPT Female | ||||||||||

| 2 | 3/4 | 200 psi @ 72° F | Hex | Brass | 1 21/32" | 150 | Brass | ASME B1.20.1, ASME B16.15, ASTM B584, NSF/ANSI 61 | 00000000 | 000000 |

- For Use With:

NPT: Air, Drinking Water, Natural Gas, Oil

BSPT: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.15, NSF/ANSI 61

BSPT: ASME B16.15, ASME BS21, ASTM B584 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges:

NPT: Use Class 150 brass

BSPT: Use Class 150 bronze

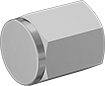

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 2 | 200 psi @ 72° F | Brass | 00000000 | 000000 |

- For Use With: Air, Drinking Water, Natural Gas, Oil

- Pressure Class: 125

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges: Use Class 150 brass

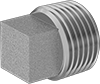

Low-Pressure Brass Threaded Pipe Fittings with Sealant

The male threads on these fittings have a sealant applied for extra protection against leaks. Also known as Pressure Class 125 fittings, they are built for use in low-pressure applications. They are brass for good corrosion resistance.

- For Use With: Air, Natural Gas, Oil, Water

- Pressure Class: 125

- Specifications Met: ASME B1.20.1, ASME B16.15

- Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges: Use Class 150 brass

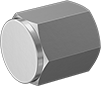

| Pipe Size | Plug Construction | Max. Pressure | Each | |

NPT Male | ||||

|---|---|---|---|---|

| 1 1/2 | Solid | 200 psi @ 72° F | 0000000 | 000000 |

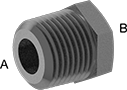

High-Pressure Brass Threaded Pipe Fittings

These fittings have the strength to handle high-pressure applications. They are brass for good corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

- For Use With: Air, Water, Natural Gas, Oil

- Specifications Met: See table

Pipe Size | ||||

|---|---|---|---|---|

| (A) | (B) | Max. Pressure | Each | |

NPT Male | ||||

| 1/2 | 3/8 | 1,000 psi @ 72° F | 0000000 | 00000 |

Medium-Pressure Brass and Bronze Threaded Pipe Fittings

Choose these fittings when you need better strength than our low-pressure brass and bronze pipe fittings. They offer good corrosion resistance.

- For Use With: Air, Natural Gas, Oil, Water

- Pressure Class: 250

- Specifications Met: ASME B1.20.1, ASME B16.15, ASTM B584

- Pipe Nipples and Pipe: Use Schedule 80 brass

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 1/2 | 400 psi @ 72° F | Brass | 0000000 | 000000 |

- For Use With: Air, Natural Gas, Oil, Water

- Specifications Met: ASME B1.20.3, ASTM B16, SAE J476

Precision Extreme-Pressure Brass Threaded Pipe Fittings

Also known as instrumentation fittings, these have the most precise threads and the tightest tolerances of all the brass pipe fittings we offer. Fittings are brass for good corrosion resistance.

- For Use With: Air, Argon, Natural Gas, Nitrogen Gas, Oil, Oxygen, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B31.1, ASME B31.3

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 1/2 | 3,600 psi @ 72° F | 1,500 psi @ 300° F | 00000000 | 000000 |

Extreme-Pressure Brass Threaded Pipe Fittings

Extreme pressures are no problem for these heavy-duty fittings. They are brass for good corrosion resistance.

- For Use WIth:

NPTF × NPTF: Air, Natural Gas, Oil, Water

All other thread types: Air, Water - Specifications Met:

NPTF × NPTF: ASME B1.20.3, ASTM B124, ASTM B16, ASTM B453, SAE J476

All other thread types: ISO 7.1, ISO 228

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female × BSPT Male | ||||

|---|---|---|---|---|

| 1/4 | 2,100 psi @ 72° F | Brass | 00000000 | 00000 |

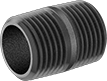

Standard-Wall Steel Threaded Pipe Nipples and Pipe

Also known as Schedule 40, this pipe is designed for low-pressure applications. Use in noncorrosive applications.

Welded pipe has a weld bead on the inside.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASME B1.20.1, DIN EN 10226, ANSI/ASME BS21

- Fittings: Use Class 150 Iron and Steel

| Pipe Size | Lg. | Construction | Material | Each | |

| 3/4 | 1 11/32" | Welded | Steel | 00000000 | 000000 |

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

Connectors with NPT threads are threaded on both ends.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Female—Threaded on Both Ends | ||||||

|---|---|---|---|---|---|---|

| 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B1.20.1, ASME B16.3, UL Listed | 000000000 | 00000 |

Low-Pressure Iron Threaded Pipe Fittings

with Right-Hand and Left-Hand Threads

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A197, ASME B16.3, ASME B1.20.1

The threads on these fittings have clockwise (right-hand) threads on one end and counterclockwise (left-hand) threads on the other end. When you use a wrench to turn, connections on both ends tighten at the same time. Use in noncorrosive environments.

| Pipe Size | Material | Each | |

NPT Female | |||

|---|---|---|---|

| 1/2 | Iron | 0000000 | 000000 |

Standard-Wall Galvanized Steel Threaded Pipe Nipples and Pipe

Made of galvanized steel, this Schedule 40 pipe has fair corrosion resistance and is designed for low-pressure applications.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: ANSI/ASME BS21, DIN EN 10226, ASME B1.20.1

- Fittings: Use Class 150 galvanized iron and galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Lg. | Construction | Each | |

| 3/4 | 1 11/32" | Welded | 00000000 | 000000 |

Low-Pressure Galvanized Iron Threaded Pipe

Fittings with Right-Hand and Left-Hand Threads

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASME B1.20.1, ASME B16.3, ASTM A197

One end of these fittings has clockwise (right-hand) threads and the other has counterclockwise (left-hand) threads. When you turn them with a wrench, both ends tighten at the same time. Since they’re threaded, their connections can be taken apart as needed for maintenance. Use them in low-pressure pipe lines. Made of galvanized iron, these fittings have fair corrosion resistance, but should be used in primarily noncorrosive environments.

| Pipe Size | Max. Pressure | Max. Steam Pressure | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 1/2 | 300 psi @ 72° F | 150 psi @ 350° F | 0000000 | 000000 |

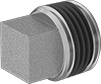

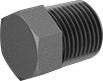

High-Pressure Iron and Steel Threaded Pipe Fittings

These fittings can stand up to high-pressure applications. Use them in noncorrosive environments.

Phosphate-coated and zinc-phosphate-coated fittings offer some corrosion resistance, but aren't intended for corrosive environments.

Note: The maximum pressure listed for Class 3000 fittings is for conditions where there are no sudden changes in pressure or velocity. Please refer to ASME B16.11 to determine the specific maximum operating pressure for your application.

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A105, ASME B16.11, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

- For Use With: Air, Hydraulic Fluid, Natural Gas, Oil, Steam, Water

- Pressure Class: 3000

- Specifications Met: ASTM A105, ASME B16.11, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 160 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Plug Construction | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Male | |||||||

|---|---|---|---|---|---|---|---|

| 1 | 16 | Solid | 6,000 psi @ 72° F | 300 psi @ 360° F | Zinc-Phosphate-Coated Steel | 00000000 | 00000 |

Compact Extreme-Pressure Steel Threaded Pipe Fittings

These fittings are strong enough to handle extreme pressures, yet small enough to fit into cramped spaces. They are zinc-plated steel, which have better corrosion resistance than plain steel fittings.

NPTF (Dryseal) threads are compatible with NPT threads. BSPP and metric male threads have either a gasket, or a gasket and washer, to prevent leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads; the male threads have either a gasket or a gasket and washer to prevent leaks.

(SAE Straight) Male

Threads with Gasket

- For Use With: See table

- Specifications Met: See table

| Pipe Size (A) | Dash Size (A) | Thread Size (B) | Dash Size (B) | Max. Pressure | Material | For Use With | Specifications Met | Each | |

NPTF Male × UN/UNF (SAE Straight) Male | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 3/8 | 06 | 9/16"-18 | 06 | 6,000 psi @ 72° F | Zinc Plated Steel | Air, Hydraulic Fluid, Water | ASTM A108 | 000000000 | 00000 |

Threads with

Gasket and Washer

- For Use With: Air, Hydraulic Fluid, Oil, Water

- Specifications Met:

BSPP × NPT: ASME B1.20.3, ISO 1179, ISO 8434-6

BSPT × NPT: ASME B1.20.3, DIN EN 10226-1, ISO 7-1

Pipe Size | Dash Size | ||||||

|---|---|---|---|---|---|---|---|

| For Use With | (A) | (B) | (A) | (B) | Max. Pressure | Each | |

BSPP Male × NPT Male | |||||||

| Air, Hydraulic Fluid, Oil, Water | 3/8 | 1/4 | 06 | 04 | 5,500 psi @ 72° F | 00000000 | 00000 |

- For Use With: Air, Hydraulic Fluid, Water

- Specifications Met: ASTM A108

| Pipe Size | Dash Size | Max. Pressure | Material | Each | |

NPTF Female | |||||

|---|---|---|---|---|---|

| 1/2 | 08 | 6,000 psi @ 72° F | Zinc Plated Steel | 000000000 | 000000 |

- Temperature Range: -20° to 230° F

| For Pipe Size | Gasket Material | Washer Material | Thickness | Each | |

For BSPP Male | |||||

|---|---|---|---|---|---|

| 3/8 | Buna-N Rubber | Steel | 2mm | 00000000 | 00000 |

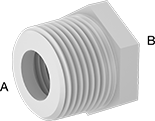

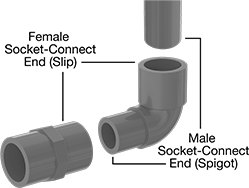

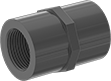

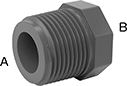

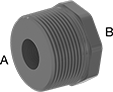

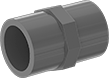

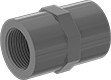

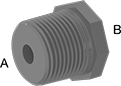

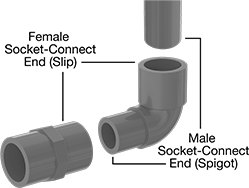

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

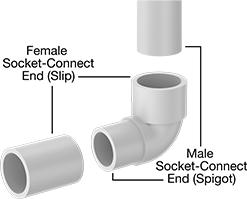

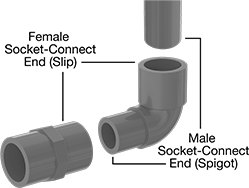

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Socket Depth | Material | Color | Each | |

| 1/4 | 5/8" | PVC Plastic | Dark Gray | 00000000 | 00000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

| Pipe Size | Material | Color | Each | |

NPT Threads | ||||

|---|---|---|---|---|

| 1/4 | PVC Plastic | Dark Gray | 0000000 | 00000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

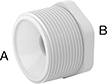

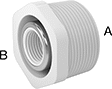

| Pipe Size (A) | Pipe Size (B) | Material | Color | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1 1/4 | 3/4 | PVC Plastic | Dark Gray | 00000000 | 00000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 372, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Drive Size | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/4 | 1 25/32" | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

UV-Resistant Polypropylene Pipe Fittings for Chemicals

Made of polypropylene, these fittings won’t deteriorate when exposed to the damaging effects of ultraviolet light and are suitable to use outdoors. They have the chemical resistance to withstand a wide variety of acids, solvents, and other harsh substances. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Schedule 80 fittings have thicker, stronger walls than Schedule 40 fittings for heavy duty, industrial chemical processing applications.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: 0° to 150° F

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

High-Purity PVDF Pipe Fittings for Corrosive Chemicals

Made of PVDF that’s finished to a 12 Ra smoothness, these fittings handle some of the harshest chemicals without leaching contaminants into your line. They won’t accumulate particles and are easy to clean, thanks to their smoothness. Comparable to Kynar, these fittings handle most organic solvents that would dissolve CPVC, and chlorine or nitric acid that would weaken polypropylene. You can use them at higher temperatures than CPVC and polypropylene. These fittings meet UL 94 V-0 and FM standards for flame retardance. They’re also FDA compliant for direct contact with food, and they meet ASTM requirements for dimensions and tolerances.

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3261, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Pipe Nipples and Pipe: Use SDR 21 PVDF Plastic

- Flanges: Use PVDF Plastic

Threaded fittings can be disconnected as needed for maintenance and repair. To prevent leaks and cracks, apply thread sealant tape (sold separately) to the male threads, and don’t overtighten them. First tighten by hand, then use a wrench to tighten one or two more turns.

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/2 | 37/64" | PVDF Plastic | White | 230 psi @ 72° F | 0000000 | 000000 |

- For Use With: Chlorine, Deionized Water, Hydrochloric Acid, Nitric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: -40° to 270° F

- Specifications Met: ASTM D3222, FDA Compliant 21 CFR 177.2510, FM 4910, UL 94 V-0

- Seal Material: Viton® Fluoroelastomer Rubber

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

PVDF Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | White | 230 psi @ 72° F | 0000000 | 0000000 |

| Each | ||

| 00000000 | 0000000 |

| For Pipe Size | Each | |

| 1/2 | 00000000 | 000000 |

- Temperature Range: -450° to 550° F

- Specifications Met: FDA Compliant 21 CFR 177.1550, MIL-T-27730, UL Listed

Max. Pressure, psi | Each | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Max. Thread Dia. | Wd. | Lg., yd. | Density, g/cm3 | Color | For Fluids | For Gases | 1-11 | 12-Up | |

PTFE | |||||||||

0.0032" Thick. | |||||||||

| 1/2" | 1/4" | 14 | 0.7 | White | 10,000 | 10,000 | 0000000 | 00000 | 00000 |

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 40 ABS Plastic

- Flanges: Use Schedule 40 ABS Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size | Drive Size | Material | Color | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 1 1/2 | 7/8" | ABS Plastic | Black | 00000000 | 00000 |

Plastic Pipe Fittings for Gasoline

Use these plastic fittings to connect gasoline fuel lines to machines and equipment. They have excellent corrosion resistance as well as high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

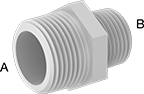

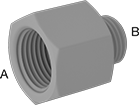

Plastic Pipe Fittings for Oil

Made of corrosion-resistant plastic, these fittings won’t deteriorate when used in oil applications. They also have high strength and impact resistance. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Oil

- Temperature Range: 0° to 230° F

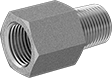

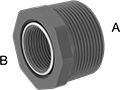

Pipe Size | ||||||

|---|---|---|---|---|---|---|

| A | B | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

| 1/2 | 1/4 | Nylon Plastic | Gray | 200 psi @ 72° F | 00000000 | 00000 |

Plastic Pipe Fittings for Food and Beverage

Made of either nylon or acetal, these fittings resist corrosion, so they won't deteriorate in food processing applications. They won’t transfer tastes or odors to your food or beverages. Since these fittings are threaded, you can take apart their connections for maintenance and repair. When connecting to another fitting, apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When threading together fittings, be careful not to overtighten them. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Nylon fittings and plugs have higher strength and temperature resistance than polyethylene, polypropylene, and other commonly used plastic fittings. These fittings are FDA compliant for repeated use with food at temperatures up to 230° F.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.