How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

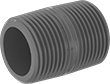

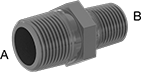

Standard-Wall Stainless Steel Threaded Pipe Nipples and Pipe

Designed for low-pressure flow applications, this pipe is also known as Schedule 40.

304 stainless steel pipe offers very good corrosion resistance. 316 stainless steel pipe has excellent corrosion resistance.

Welded pipe has a weld bead on the inside.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Natural Gas, Steam, Oil, Water, Air

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 150 stainless steel

- Flanges: Use Class 150 stainless steel

| Pipe Size | Lg. | Construction | Each | |

| 4 | 2 7/8" | Welded | 00000000 | 000000 |

- For Use With: Natural Gas, Steam, Oil, Water, Air

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 150 stainless steel

- Flanges: Use Class 150 stainless steel

| Pipe Size | Lg. | Construction | Each | |

| 4 | 2 7/8" | Welded | 00000000 | 000000 |

Low-Pressure Stainless Steel Threaded Pipe Fittings

Use these fittings in a low-pressure pipe line.

Fittings that meet ANSI/MSS SP-114 adhere to high-quality standards for heat treating, material thickness, and marking. 304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

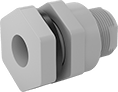

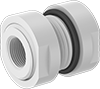

Through-wall fittings are also known as bulkhead couplings; they mount through your wall or tank to create an inlet or outlet. When installing, the gasket should be on the inside of the tank.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 150

- Fabrication: Heat Treated

- Specifications Met:

NPT: ANSI/MSS SP-114, ASTM A351

BSPP and BSPT: ANSI/MSS SP-114 - Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

- For Use With: Water

- Temperature Range: -20° to 300° F

316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Hole Dia. | For Max. Wall Thick. | Lg. | Hex Wd. | Gasket Material | Max. Pressure | Each | |

NPT Female | ||||||||

| 1 | 2 1/4" | 1 3/8" | 2 7/8" | 3 1/16" | EPDM Rubber | 300 psi @ 72° F | 0000000 | 0000000 |

Thick-Wall Stainless Steel Threaded Pipe Nipples and Pipe

Thick walls, also known as Schedule 80, give this pipe the strength to handle high-pressure applications. It is seamless so it has a smooth interior for unrestricted flow.

304 stainless steel pipe has very good corrosion resistance. 316 stainless steel pipe has excellent corrosion resistance. Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Hydraulic Fluid, Natural Gas, Oil, Steam

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 3000 stainless steel

- Flanges: Use Use Class 300 or 600 stainless steel

| Pipe Size | Dash Size | Lg. | Thread Type | Construction | Each | |

| 4 | 64 | 2 7/8" | NPT | Seamless | 000000000 | 0000000 |

- For Use With: Air, Water, Hydraulic Fluid, Natural Gas, Oil, Steam

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 3000 stainless steel

- Flanges: Use Use Class 300 or 600 stainless steel

| Pipe Size | Dash Size | Lg. | Thread Type | Construction | Each | |

| 4 | 64 | 2 7/8" | NPT | Seamless | 00000000 | 0000000 |

Medium-Pressure Stainless Steel Threaded Pipe Fittings

Choose these fittings when you want the same high-quality found in our low-pressure pipe fittings, but need more strength to handle higher pressures.

Fittings that meet ANSI/MSS SP-114 adhere to high-quality standards for heat treating, material thickness, and marking.

304 stainless steel fittings have very good corrosion resistance.

316 stainless steel fittings have excellent corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Pressure Class: 1000

- Specifications Met: ANSI/MSS SP-114, ASTM A182

- Pipe Nipples and Pipe: Use Schedule 40 stainless steel

- Flanges: Use Class 150 stainless steel

Standard-Wall Brass Threaded Pipe Nipples and Pipe

Also known as Schedule 40, this pipe is for use in low-pressure flow applications. It is brass, which offers good corrosion resistance. Pipe is seamless and has a smooth interior for unrestricted flow.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

To adhere to safety standards for drinking water systems, use pipe that meets NSF/ANSI 61.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Drinking Water, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM B687, NSF/ANSI 61

- Fittings: Use Class 125 brass or bronze

- Flanges: Use Class 150 brass or bronze

| Pipe Size | Lg. | Construction | Each | |

| 4 | 2 7/8" | Seamless | 00000000 | 000000 |

Low-Pressure Brass and Bronze Threaded Pipe Fittings

Use these fittings in low-pressure flow applications. They have good corrosion resistance. Fittings rated for use with drinking water meet NSF/ANSI 61 safety standards.

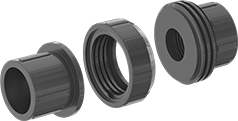

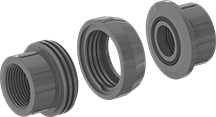

Union connectors separate into three pieces so you can access your line without unthreading pipe connections.

For technical drawings and 3-D models, click on a part number.

- For Use With:

NPT: Air, Drinking Water, Natural Gas, Oil

BSPT: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.15, NSF/ANSI 61

BSPT: ASME B16.15, ASME BS21, ASTM B584 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges:

NPT: Use Class 150 brass

BSPT: Use Class 150 bronze

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 2 1/2 | 200 psi @ 72° F | Brass | 00000000 | 0000000 |

- For Use With:

NPT: Air, Drinking Water, Natural Gas, Oil

BSPT: Air, Natural Gas, Oil, Steam, Water - Pressure Class: 125

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.15, NSF/ANSI 61

BSPT: ASME BS21, ASTM B584 - Pipe Nipples and Pipe: Use Schedule 40 brass

- Flanges:

NPT: Use Class 150 brass

BSPT: Use Class 150 bronze

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 2 | 200 psi @ 72° F | Brass | 00000000 | 0000000 |

Standard-Wall Steel Threaded Pipe Nipples and Pipe

Also known as Schedule 40, this pipe is designed for low-pressure applications. Use in noncorrosive applications.

Welded pipe has a weld bead on the inside.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A53

- Fittings: Use Class 125 or 150 Iron and Steel

| Pipe Size | Lg. | Construction | Material | Each | |

| 4 | 2 7/8" | Welded | Steel | 000000000 | 000000 |

Low-Pressure Iron and Steel Threaded Pipe Fittings

Use these fittings for low-pressure applications in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Specifications Met | Each | |

NPT Female—Threaded on Both Ends | ||||||

|---|---|---|---|---|---|---|

| 2 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Iron | ASME B1.20.1, ASME B16.3, UL Listed | 00000000 | 000000 |

FM-Approved Low-Pressure Cast Iron Threaded Pipe Fittings

Suitable for use in fire-protection applications, these pipe fittings are made of cast iron, so they are brittle and can be quickly opened with the strike of a sledge hammer. They are also known as Pressure Class 125 fittings. Use in noncorrosive environments.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 125

- Specifications Met: FM Approved, UL Listed, ASTM A126, ASME B1.20.1, ASME B16.4

- Pipe Nipples and Pipe: Use Schedule 40 steel

Standard-Wall Galvanized Steel Threaded Pipe Nipples and Pipe

Made of galvanized steel, this Schedule 40 pipe has fair corrosion resistance and is designed for low-pressure applications.

Welded pipe has a weld bead on the inside.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A53

- Fittings: Use Class 125 or 150 galvanized iron and galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Lg. | Construction | Each | |

| 4 | 2 7/8" | Welded | 00000000 | 000000 |

Low-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

The galvanized finish on these fittings provides fair corrosion resistance. Fittings are for use in low-pressure applications.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class: 150

- Specifications Met:

NPT: ASME B1.20.1, ASME B16.3, ASTM A197, UL Listed

BSPT: ASTM A197, DIN EN 10226 - Pipe Nipples and Pipe: Use Schedule 40 galvanized steel

- Flanges: Use Class 150 galvanized steel

| Pipe Size | Max. Pressure | Max. Steam Pressure | Material | Each | |

NPT Female—Threaded on Both Ends | |||||

|---|---|---|---|---|---|

| 2 1/2 | 150 psi @ 72° F | 150 psi @ 350° F | Galvanized Iron | 00000000 | 000000 |

Thick-Wall Steel Threaded Pipe Nipples and Pipe

Also known as Schedule 80, this pipe has thick walls for good strength in medium-pressure applications.

Seamless pipe has a smooth interior for unrestricted flow and is stronger than welded pipe. A phosphate coating gives it some corrosion resistance, but this pipe shouldn’t be used in corrosive environments.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: See table

- Fittings: Use Class 300 iron or steel

- Flanges: Use Class 300 or 600 steel

| Pipe Size | Lg. | Material | Specifications Met | Each | |

Seamless | |||||

|---|---|---|---|---|---|

| 4 | 2 7/8" | Phosphate-Coated Steel | ASME B1.20.1, ASTM A106, ASTM A53, ASTM A733 | 00000000 | 000000 |

Medium-Pressure Iron and Steel Threaded Pipe Fittings

With better strength than our low-pressure iron and steel pipe fittings, these can handle medium-pressure applications. They are for use in noncorrosive environments.

Straight connectors with recessed threading have a short unthreaded space on each end, which allows for easy alignment when threading onto long lengths of pipe. They are also known as API line couplings.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 300

- Specifications Met: ASTM A197, UL Listed, ASME B16.3, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 or 600 steel

- For Use With: Air, Water, Oil, Natural Gas

- Specifications Met: ASTM A105, ASTM A53

- Pipe Nipples and Pipe: Use Schedule 160 or 80 steel

- Flanges: Use Class 300 or 600 steel

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 2 | 300 psi @ 72° F | Steel | 000000000 | 000000 |

Medium-Pressure Galvanized Iron and Steel Threaded Pipe Fittings

A galvanized finish gives these fittings fair corrosion resistance. They have the strength to handle medium-pressure applications.

Straight connectors with recessed threading have a short unthreaded space on each end, which allows for easy alignment when threading onto long lengths of pipe. They are also known as API line couplings.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Steam, Water

- Pressure Class : 300

- Specifications Met: ASTM A153, ASTM A197, ASME B16.3, ASME B1.20.1

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

- For Use With: Air, Water, Oil, Natural Gas

- Specifications Met: ASTM A105, ASTM A53

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

| Pipe Size | Max. Pressure | Material | Each | |

NPT Female | ||||

|---|---|---|---|---|

| 2 | 300 psi @ 72° F | Galvanized Steel | 000000000 | 000000 |

Extra-Thick-Wall Steel Threaded Pipe Nipples and Pipe

Extra-thick walls give this pipe excellent strength to handle high-pressure applications. It is also known as Schedule 160. Pipe is seamless, so it has a smooth interior for unrestricted flow. A phosphate coating gives this pipe some corrosion resistance, but it shouldn’t be used in corrosive environments.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Water, Oil, Natural Gas, Steam, Hydraulic Fluid

- Specifications Met: ASME B1.20.1, ASTM A106, ASTM A53, ASTM A733

- Fittings: Use Class 3000 steel

- Flanges: Use Class 1500 steel

| Pipe Size | Dash Size | Lg. | Thread Type | Construction | Material | Each | |

| 4 | 64 | 2 7/8" | NPT | Seamless | Phosphate-Coated Steel | 00000000 | 0000000 |

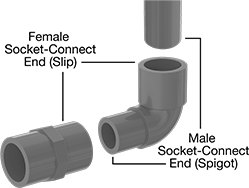

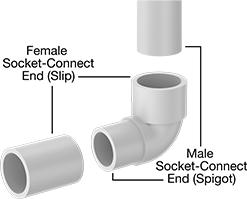

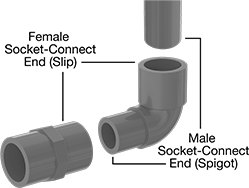

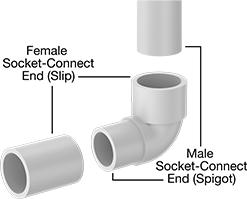

High-Pressure Socket-Connect Steel Unthreaded Pipe Fittings

Socket-connect fittings are easier to weld than butt-weld fittings because the fitting doesn’t need to align perfectly to the pipe. Slide pipe into the socket and weld for a strong, permanent connection. Fittings have heavy duty construction that stands up to high-pressure applications. They are for use in noncorrosive environments.

Union straight connectors separate into three pieces for access to your line.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Pressure Class : 3000

- Specifications Met: ASTM A105, MSS SP-83

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 and 600 steel

| Pipe Size | Max. Pressure | Material | Each | |

| 1 1/4 | 3,000 psi @ 72° F | Steel | 000000000 | 000000 |

Standard-Wall Aluminum Threaded Pipe Nipples and Pipe

Made of aluminum, this pipe is lightweight with good corrosion resistance. Also known as Schedule 40 pipe, it is for use in low-pressure applications. It is seamless, which provides a smooth interior for unrestricted flow.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Oil, Water

- Specifications Met: ASTM B241

- Fittings: Use Class 150 aluminum

- Flanges: Use Class 125 aluminum

| Pipe Size | Lg. | Construction | Each | |

| 4 | 2 7/8" | Seamless | 000000000 | 000000 |

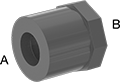

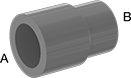

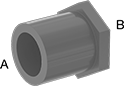

Thin-Wall Socket-Connect Aluminum Unthreaded Pipe Fittings

Socket-connect fittings are easier to weld than butt-weld fittings because the fitting doesn’t need to align perfectly to the pipe. Slide pipe into the socket and weld for a strong, permanent connection. Fittings are aluminum, which is lightweight with good corrosion resistance.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Oil, Water

- Specifications Met: ASTM B361

- Pipe: Use Schedule 10 aluminum

Pipe Size | Wall Thick. | ||||

|---|---|---|---|---|---|

| (A) | (B) | (A) | (B) | Each | |

| 2 | 1 1/2 | 0.109" | 0.109" | 0000000 | 000000 |

- For Use With: Air, Oil, Water

- Specifications Met: ASTM B361

- Pipe: Use Schedule 10 aluminum

| Pipe Size | Wall Thick. | Each | |

| 1 1/2 | 0.109" | 0000000 | 000000 |

Thick-Wall Plastic Pipe for Water

With thicker, stronger walls than standard-wall pipe, this Schedule 80 pipe can handle heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. It’s made of PVC, which has good corrosion resistance. Pipe meets ASTM D1784 and ASTM D1785 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785

- Fittings: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

Clear-View Thick-Wall Plastic Pipe for Water

See what’s flowing through your line with this clear pipe. Since it’s Schedule 80, this pipe has thicker, stronger walls than standard-wall pipe, so you can use it for heavy duty industrial plumbing and water supply applications, such as water processing, waste water treatment, and irrigation. It’s made of PVC, which has good corrosion resistance. This pipe meets ASTM D1784 and ASTM D1785 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D1785

- Fittings: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection, be careful not to overtighten the threads. To prevent cracks and leaks, finger-tighten the fitting, then wrench-tighten for one to two turns.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

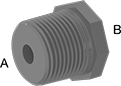

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | O-Ring Material | Color | Each | |

NPT Threads | |||||

|---|---|---|---|---|---|

| 2 | PVC Plastic | Viton® Fluoroelastomer Rubber | Dark Gray | 0000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Unions separate into three pieces so you can access your line.

| Pipe Size | Socket Depth | Material | O-Ring Material | Color | Each | |

BSPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1 1/2 | 1 3/32" | PVC Plastic | EPDM Rubber | Dark Gray | 0000000 | 0000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Unions separate into three pieces so you can access your line.

| Pipe Size | DIN Size, mm | Socket Depth, mm | Material | O-Ring Material | Color | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/4 | 40 | 26 | PVC Plastic | EPDM Rubber | Dark Gray | 00000000 | 0000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 372, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80

| Pipe Size (A) | Pipe Size (B) | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1 1/2 | 1 | PVC Plastic | Dark Gray | 235 psi @ 72° F | 00000000 | 000000 |

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

(A) | (B) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size | Socket Depth | Material | Color | Each | |

| 4 | 4 1/2" | 3.826" | 0.337" | 1 | 1 1/8" | PVC Plastic | Dark Gray | 00000000 | 000000 |

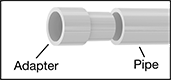

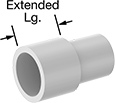

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

Female × male socket-connect straight adapters are also known as pipe extenders; use them when your pipe is too short to accept a fitting.

| Pipe Size | Socket Depth | OD | ID | Wall Thick. | Extended Lg. | Material | Color | Specifications Met | Each | |

| 2 | 1 1/8" | 2 3/8" | 2.067" | 0.154" | 1 1/4" | PVC Plastic | White | ASTM D1784, NSF/ANSI 61 | 00000000 | 000000 |

CPVC Pipe for Hot Water

Made of CPVC, this pipe can withstand high temperatures up to 170° or 200° F. It meets NSF/ANSI Standard 61 for drinking water. Also known as Schedule 80 pipe, it has thick, strong walls for use in heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. Pipe has good corrosion resistance. It is comparable to Corzan.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

ASTM D1784 pipe meets specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Fittings: Use Schedule 80 CPVC plastic

- Flanges: Use Class 150 CPVC plastic

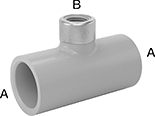

CPVC Pipe Fittings for Hot Water

Made of CPVC, these fittings can handle high temperatures. They have thick, strong walls to handle heavy duty industrial plumbing and water supply applications, such as water processing and waste water treatment. They also have good corrosion resistance. These fittings are comparable to Corzan. Some meet ASTM D1784 specifications and testing requirements for material quality.

Fittings for drinking water meet NSF/ANSI Standard 61.

Schedule 80 fittings have thick, strong walls for heavy duty, industrial applications.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local regulatory limits on VOCs (Volatile Organic Compounds).

For technical drawings and 3-D models, click on a part number.

- For Use With: Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 180° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall, tank, or panel to create an inlet or outlet for faucets, pipes, and spigots.

| Pipe Size | Socket Depth | For Hole Dia. | For Max. Wall Thick. | Material | Gasket Material | Schedule | Color | Max. Pressure | Each | |

| 3/4 | 1 1/64" | 1 5/8" | 1 5/64" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | 1 9/64" | 1 7/8" | 1 5/64" | CPVC Plastic | EPDM Rubber | 80 | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

- For Use With:

Fittings with EPDM Rubber O-Rings: Drinking Water, Water

All other fittings: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water - Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | O-Ring Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 2 | CPVC Plastic | Viton® Fluoroelastomer Rubber | 80 | Light Gray | Not Rated | 0000000 | 000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

(A) | (B) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Socket Depth | Pipe Size | Socket Depth | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

| 1 1/2 | 1 3/8" | 3/4 | 1" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 000000 |

| 1 1/2 | 1 3/8" | 1 | 1 1/8" | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 00000 |

| Pipe Cement for Max. Pipe Size 6 | 00000000 | Each | 000000 |

- For Use With: See table

- Maximum Temperature: 200° F

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

(A) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | OD | ID | Wall Thick. | Pipe Size (B) | For Use With | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||||||

| 4 | 4 1/2" | 3.826" | 0.337" | 2 | Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

| Pipe Size (A) | Pipe Size (B) | Material | Schedule | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 6 | 4 | CPVC Plastic | 80 | Light Gray | Not Rated | 00000000 | 0000000 |

- For Use With: Acetic Acid (10%), Calcium Chloride, Deionized Water, Drinking Water, Hydrochloric Acid (25%), Nitric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide (50%), Sulfuric Acid (75%), Water

- Maximum Temperature: 200° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 80 CPVC Plastic

- Flanges: Use Class 150 CPVC Plastic

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a CPVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant to the male threads. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Inline tees are also known as branch tees.

Fittings with a stainless steel collar have reinforced female threads to prevent cracking.

UV-Resistant Standard-Wall PVC Pipe Fittings for Water

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

Use these fittings in outdoor environments—the material has an additive that protects against the damaging effects of ultraviolet light. Fittings meet NSF/ANSI Standard 61 for drinking water. Also known as Schedule 40 fittings, they are typically used in residential and commercial low-pressure plumbing and water supply applications. They are PVC, which has good corrosion resistance. Fittings meet ASTM D1784 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

UV-Resistant Polypropylene Pipe Fittings for Chemicals

Made of polypropylene, these fittings won’t deteriorate when exposed to the damaging effects of ultraviolet light and are suitable to use outdoors. They have the chemical resistance to withstand a wide variety of acids, solvents, and other harsh substances. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Schedule 80 fittings have thicker, stronger walls than Schedule 40 fittings for heavy duty, industrial chemical processing applications.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: See table

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

High-Temperature PTFE Pipe Fittings for Chemicals

Extreme temperatures are no problem for these fittings—they’re made of PTFE, so they can withstand a wider temperature range than any of our other plastic pipe fittings for chemicals. They have the chemical resistance to stand up to acid and solvents. Fittings have thick, Schedule 80 walls for heavy duty industrial applications. The material won’t leach contaminates into the line, so these fittings are commonly used in high-purity processes, such as semiconductor and clean room applications. They have a super-smooth interior for unrestricted flow. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns. Fittings meet ASTM D1710 specifications and testing requirements for material quality.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

- For Use With: Deionized Water, Hydrochloric Acid, Solvents

- Temperature Range: -70° to 400° F

- Specifications Met: ASTM D1710

- Pipe Nipples and Pipe: Use Schedule 80 PTFE Plastic

- Flanges: Use Class 150 PTFE Plastic

Through-wall fittings are also known as bulkhead couplings and panel-mount couplings; they mount through a wall, tank, or panel to create an inlet or outlet for faucets, pipes, and spigots. They are for use on flat and curved surfaces.

Underground PVC Pipe Fittings for Drain, Waste, and Vent

With thinner walls than Schedule 40 fittings, these are lighter in weight and have more space on the inside for high-flow applications, such as underground gravity-flow sewer and storm drainage lines. They are also known as SDR 35 fittings. Made of PVC, they have good strength and corrosion resistance. All meet an ASTM specification and testing requirement for material quality, dimensions, and workmanship.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld). Threaded connections can be taken apart as needed for maintenance and repair.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

For technical drawings and 3-D models, click on a part number.

To prevent leaks in threaded connections, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.