How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

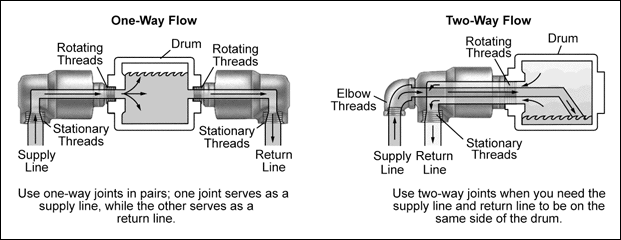

About Rotating Joints

Rotating joints transfer hot and cold materials from your supply line to a continuously revolving drum, roller, or other rotating equipment.

Pipe size is an industry designation, not the actual size. View information about how to measure pipe size threads.

More

Selecting and Measuring Expansion Joints

For information about selecting pipe size, see Selecting and Measuring Pipe & Fittings.

More

Standard-Wall Stainless Steel Threaded Pipe Nipples and Pipe

Designed for low-pressure flow applications, this pipe is also known as Schedule 40.

304 stainless steel pipe offers very good corrosion resistance. 316 stainless steel pipe has excellent corrosion resistance.

Seamless pipe has a smooth interior for unrestricted flow and is stronger than welded pipe.

Welded pipe has a weld bead on the inside.

For technical drawings and 3-D models, click on a part number.

- For Use With: Natural Gas, Oil, Steam, Water, Air

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 150 stainless steel

- Flanges: Use Class 150 stainless steel

| Lg. | Construction | Each | |

1/8 Pipe Size | |||

|---|---|---|---|

| 7 1/2" | Seamless | 00000000 | 00000 |

1/4 Pipe Size | |||

| 7 1/2" | Seamless | 00000000 | 0000 |

3/8 Pipe Size | |||

| 7 1/2" | Seamless | 00000000 | 00000 |

1/2 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

3/4 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

1 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

1 1/4 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

1 1/2 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

2 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

3 Pipe Size | |||

| 7 1/2" | Welded | 00000000 | 00000 |

- For Use With: Natural Gas, Steam, Oil, Water, Air

- Specifications Met: ASTM A733, ASME B1.20.1

- Fittings: Use Class 150 stainless steel

- Flanges: Use Class 150 stainless steel

Standard-Wall Steel Threaded Pipe Nipples and Pipe

Also known as Schedule 40, this pipe is designed for low-pressure applications. Use in noncorrosive applications.

Welded pipe has a weld bead on the inside.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A53

- Fittings: Use Class 125 or 150 Iron and Steel

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM A733, ASME B1.20.1, ASTM A53

- Fittings: Use Class 125 or 150 Iron and Steel

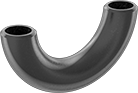

Standard-Wall Butt-Weld Steel Unthreaded Pipe Fittings

Butt-weld fittings allow for a smooth connection that provides maximum flow. They have beveled ends that, when flush to pipe, create a trough for a strong, permanent weld. Fittings are also known as Schedule 40. They are for use in noncorrosive environments.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234, ASME B16.9

- Pipe Nipples and Pipe: Use Schedule 40 steel

- Flanges: Use Class 150 steel

| Pipe Size | Wall Thickness | Construction | Each | |

| 2 1/2 | 0.203" | Seamless | 000000000 | 0000000 |

Thick-Wall Butt-Weld Steel Unthreaded Pipe Fittings

With thicker, stronger walls than our standard-wall butt-weld pipe fittings, these fittings stand up to your high strength applications. Weld them flush against pipe for a smooth connection that permits maximum flow. These fittings have beveled ends that create a trough for a leak-resistant, permanent weld. Made of steel, they’re for use in noncorrosive environments.

180° bend connectors are also known as U-bends.

For technical drawings and 3-D models, click on a part number.

- For Use With: Air, Steam, Oil, Water, Natural Gas

- Specifications Met: ASTM A234

- Pipe Nipples and Pipe: Use Schedule 80 steel

- Flanges: Use Class 300 steel

| Pipe Size | Wall Thick. | Construction | Each | |

| 2 1/2 | 0.276" | Seamless | 0000000 | 0000000 |

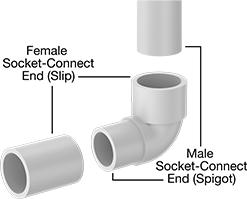

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: See table

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

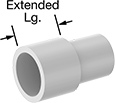

Female × male socket-connect straight adapters are also known as pipe extenders; use them when your pipe is too short to accept a fitting.

| Pipe Size | Socket Depth | OD | ID | Wall Thick. | Extended Lg. | Material | Color | Specifications Met | Each | |

| 6 | 3 11/16" | 6 5/8" | 6.065" | 0.28" | 4" | PVC Plastic | White | ASTM D1784, ASTM D1785, NSF/ANSI 61 | 00000000 | 0000000 |

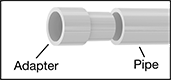

Medium-Pressure Clamp-On Connectors

Create quick, liquid-tight connections in medium-pressure applications with these connectors. They join rigid pipe of the same or different materials. Connectors have a gasket that permits moderate movement and misalignment of pipe ends.

Compression connectors slide onto pipe and hand tighten with the end nuts. You may need to tighten over time. These connectors have a Buna-N rubber gasket that resists oil, as well as mild chemicals and water. Replace the gasket when it’s worn out, or swap it out for a gasket with different properties. PVC connectors are lighter in weight and more economical than metal connectors.

For technical drawings and 3-D models, click on a part number.

- For Use With: Water

- Temperature Range: 32° to 73° F

- For Pipe Material: Steel, PVC Plastic

| For Pipe OD | For Pipe Size | Lg. | Pipe Connection Type | Max. Pressure | Gasket Material | Each | |

| 2 3/8" | 2 | 7 1/2" | Compression | 125 psi @ 72° F | Buna-N Rubber | 00000000 | 000000 |

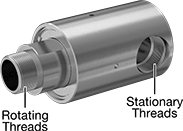

Stainless Steel One-Way-Flow Rotating Joints

- For Use With: Air, Oil, Steam, Water

- Maximum Temperature:

Oil: 390° F

Steam: 350° F

Water: 300° F - Maximum Pressure:

Air: 300 psi @ 72° F

Oil: 100 psi @ 72° F

Steam: 120 psi @ 350° F

Water: 750 psi @ 72° F - Maximum Vacuum: 25 in. of Hg @ 72° F

These joints have a rotating shaft with threads on one end that connect to a continuously revolving drum, roller, or other rotating equipment. Use them to transfer hot and cold materials from your supply line. Joints are for one-way flow and are meant to be used in pairs—one joint serves as the supply line while the other serves as the return line. Joints are stainless steel for excellent resistance to corrosion caused by fluid flowing through them.

If your drum rotates counterclockwise as you face the connecting end, you should select a rotating joint with right-handed threads. If your drum rotates clockwise as you face the connecting end, you should select a rotating joint with left-handed threads.

For technical drawings and 3-D models, click on a part number.

Rotating Threads | Stationary Threads | Max. Speed, rpm | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Thread Direction | Air | Water | Oil | Steam | Body Dia. | Lg. | Material | Shaft Material | Each | |

Right-Hand Rotating Threads | ||||||||||||||||

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | Right Hand | 550 | 1,000 | 1,000 | 1,000 | 3 1/2" | 7 1/2" | 300 Series Stainless Steel | Stainless Steel | 00000000 | 0000000 |

Left-Hand Rotating Threads | ||||||||||||||||

| 1 1/4 | NPT | Male | 1 1/4 | NPT | Female | Right Hand | 550 | 1,000 | __ | __ | 3 1/2" | 7 1/2" | 300 Series Stainless Steel | Stainless Steel | 00000000 | 000000 |

Stainless Steel Two-Way-Flow Rotating Joints

- For Use With: Air, Oil, Steam, Water

- Maximum Temperature:

Oil: 390° F

Steam: 350° F

Water: 300° F - Maximum Pressure:

Air: 300 psi @ 72° F

Oil: 100 psi @ 72° F

Steam: 120 psi @ 350° F

Water: 750 psi @ 72° F - Maximum Vacuum: 25 in. of Hg @ 72° F

These joints have a rotating shaft with threads on one end that connect to a continuously revolving drum, roller, or other rotating equipment. Use them to transfer hot and cold materials from your supply line. They are for two-way flow and are meant to be used when you need the supply line and the return line to be on the same side of your equipment. Joints are stainless steel for excellent resistance to corrosion caused by fluid flowing through them.

If your drum rotates counterclockwise as you face the connecting end, you should select a rotating joint with right-handed threads. If your drum rotates clockwise as you face the connecting end, you should select a rotating joint with left-handed threads.

For technical drawings and 3-D models, click on a part number.

Rotating Threads | Stationary Threads | Elbow Threads | Max. Speed, rpm | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Pipe Size | Thread Type | Gender | Air | Oil | Steam | Water | Body Dia. | Lg. | Material | Shaft Material | Each | |

Right-Hand Rotating Threads | ||||||||||||||||||

| 1 | NPT | Male | 1 | NPT | Female | 1/2 | NPT | Female | 550 | 1,000 | 1,000 | 1,000 | 3 1/8" | 7 1/2" | 300 Series Stainless Steel | Stainless Steel | 00000000 | 0000000 |

Left-Hand Rotating Threads | ||||||||||||||||||

| 1 | NPT | Male | 1 | NPT | Female | 1/2 | NPT | Female | 550 | __ | __ | 1,000 | 3 1/8" | 7 1/2" | 300 Series Stainless Steel | Stainless Steel | 00000000 | 000000 |

Expansion Joints with Butt-Weld Ends

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Temperature Range: -20° to 800° F

- Maximum Pressure: 150 psi @ 72° F

- Maximum Vacuum: 29 in. of Hg @ 72° F

These joints weld to unthreaded pipe or another butt-weld fitting for a leak-resistant, permanent connection. They reduce stress, vibration, and noise in metal piping systems by providing a point of flexibility to absorb movement.

For technical drawings and 3-D models, click on a part number.

Distance | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Pipe OD | Pipe Size | Lg. | Compression | Expansion | Offset | Expansion Joint Type | Butt Weld End Material | Each | |

321 Stainless Steel | |||||||||

| 5 9/16" | 5 | 7 1/2" | 5/8" | 1/4" | 1/16" | Bellow | Steel | 0000000 | 0000000 |