Filter by

Nose Material

Body Material

Usable Length

End Type

Nose Diameter

Material

Handle Material

Body Length

Locking Type

Extended Nose Force

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Compressed Nose Force

Extended Nose Length

Drive Style

Clamping Quick-Release Pins

The spring-loaded shaft draws thin sheets of material together and clamps them between the pin’s head and retaining balls. These pins are often used to secure sheet metal while welding to keep the sheets from sliding as you work. Press the button to extend the pin’s shaft and release to retract it up to 5 mm into the head.

Corrosion-Resistant Stainless Steel with Plastic Lanyard

|

Keep pins from getting lost when removed by securing the end of the attached lanyard to equipment.

18-8 Stainless Steel—The choice for wet and outdoor environments, these pins resist rusting. They are strong enough to join most components but won't withstand stress and vibration as well as steel.

Usable Lg., mm | Dia. at Extended Ball Ht., mm | Double Shear Breaking Strength, lbf | Min. Hardness | Handle Material | Ball Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 7 | 4,700 | Brinell 150 | Plastic | Stainless Steel | 93042A510 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 7 | 4,700 | Brinell 150 | Plastic | Stainless Steel | 93042A540 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 9.5 | 8,500 | Brinell 150 | Plastic | Stainless Steel | 93042A570 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 9.5 | 8,500 | Brinell 150 | Plastic | Stainless Steel | 93042A600 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 to 5 | 12 | 13,400 | Brinell 150 | Plastic | Stainless Steel | 93042A630 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 12 | 13,400 | Brinell 150 | Plastic | Stainless Steel | 93042A660 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 to 10 | 14 | 19,500 | Brinell 150 | Plastic | Stainless Steel | 93042A720 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

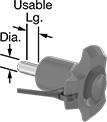

T-Handle Quick-Release Pins

With the widest grip, these pins give you the most leverage. They’re the easiest to grab with gloved or slippery hands but take up the most space when installed. Pins have a retaining ball to hold them in place until you pull to remove.

Steel

|

Plastic Handle |

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Usable Lg. | Dia. at Extended Ball Ht. | Single Shear Breaking Strength, lbf | Min. Hardness | Handle Color | Ball Material | 1-49 | 50-249 | 250-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel with Plastic Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.286" | 3,800 | Rockwell B85 | Black | Stainless Steel | 92490A648 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.286" | 3,800 | Rockwell B85 | Black | Stainless Steel | 92490A650 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.286" | 3,800 | Rockwell B85 | Black | Stainless Steel | 92490A651 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.286" | 3,800 | Rockwell B85 | Black | Stainless Steel | 92490A310 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.286" | 3,800 | Rockwell B85 | Black | Stainless Steel | 92490A320 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/16" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 0.356" | 6,300 | Rockwell B85 | Black | Stainless Steel | 92490A330 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.356" | 6,300 | Rockwell B85 | Black | Stainless Steel | 92490A340 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.356" | 6,300 | Rockwell B85 | Black | Stainless Steel | 92490A652 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.356" | 6,300 | Rockwell B85 | Black | Stainless Steel | 92490A350 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.356" | 6,300 | Rockwell B85 | Black | Stainless Steel | 92490A653 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A360 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A654 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A655 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A656 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/2" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A657 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A658 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 0.426" | 7,800 | Rockwell B85 | Black | Stainless Steel | 92490A659 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 0.57" | 13,600 | Rockwell B85 | Black | Stainless Steel | 92490A660 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.57" | 13,600 | Rockwell B85 | Black | Stainless Steel | 92490A661 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel with Plastic Lanyard

|

Plastic Handle |

Keep pins from getting lost when removed by securing the end of the attached lanyard to equipment.

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Usable Lg. | Dia. at Extended Ball Ht. | Single Shear Breaking Strength, lbf | Min. Hardness | Handle Color | Ball Material | 1-49 | 50-249 | 250-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Carbon Steel with Plastic Handle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.286" | 1,900 | Rockwell C26 | Black | Stainless Steel | 92490A511 | 000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.286" | 1,900 | Rockwell C26 | Black | Stainless Steel | 92490A514 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.286" | 1,900 | Rockwell C26 | Black | Stainless Steel | 92490A518 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Stainless Steel | 92490A533 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Stainless Steel | 92490A536 | 00000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 0.57" | 7,700 | Rockwell C26 | Black | Stainless Steel | 92490A539 | 00000 | 00000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

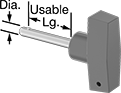

Ball-Grip Quick-Release Pins

The smooth, round head is comfortable to grip and won't catch on other parts. These pins have a retaining ball that holds them in place until you pull to remove.

Steel

|

Zinc-Plated Carbon Steel—These pins withstand occasional exposure to moisture. However, since friction from moving parts can wear away the finish, they're not ideal for wet environments. While not nearly as corrosion resistant as stainless steel, they are stronger and won’t deform under stress.

Usable Lg. | Dia. at Extended Ball Ht. | Single Shear Breaking Strength, lbf | Min. Hardness | Handle Color | Handle Material | Ball Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/4" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A567 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A571 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 0.286" | 1,900 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A575 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A582 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 0.426" | 4,300 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A585 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/4" | 0.57" | 7,700 | Rockwell C26 | Black | Plastic | Stainless Steel | 92490A589 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

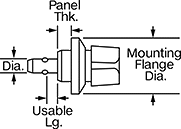

Quick-Release Pins for Blind Holes

Often used to position and hold parts during assembly and inspection, mate these pins with a receptacle to secure them in blind holes. Install the receptacle (sold separately) in the hole so you can insert the pin to join components. Three retaining balls lock pins in place until released.

Twist Knob

|  |

No button to hold down, these pins secure and release with just a quarter turn of the knob.

Nickel-Plated Carbon Steel—With a durable finish, these pins resist rust, salt water, and mild chemicals.

Quick-Release Pins | Receptacles | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia., mm | Usable Lg., mm | For Panel Thk., mm | Mounting Flange Dia., mm | Double Shear Breaking Strength | Min. Hardness | Handle Color | Handle Material | Ball Material | Mounting Fasteners Included | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 10.5 | 6 to 10 | 25 | Not Rated | Not Rated | Black | Plastic | Stainless Steel | Yes | 97580A311 | 000000 | 99802A211 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 10.5 | 6 to 14 | 34 | Not Rated | Not Rated | Black | Plastic | Stainless Steel | Yes | 97580A312 | 00000 | 99802A212 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

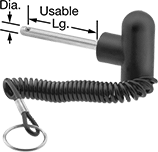

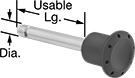

Knob-Grip Quick-Release Pins

With a head that's tall and narrow, these pins fit in tighter spaces than a loop or T-handle while still giving you something to grab. The head also has a hole for adding a split ring and a lanyard (sold separately). A retaining ball holds pins in place until you pull to remove.

Corrosion-Resistant Stainless Steel

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these pins resist rusting. They are strong enough to join most components but won't withstand stress and vibration as well as steel.

Usable Lg., mm | Dia. at Extended Ball Ht., mm | Single Shear Breaking Strength, lbf | Min. Hardness | Handle Material | Ball Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

6 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 6.5 | 4,900 | Brinell 150 | Plastic | Stainless Steel | 95335A623 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 6.5 | 4,900 | Brinell 150 | Plastic | Stainless Steel | 95335A624 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 6.5 | 4,900 | Brinell 150 | Plastic | Stainless Steel | 95335A625 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

8 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 8.7 | 8,900 | Brinell 150 | Plastic | Stainless Steel | 95335A626 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 8.7 | 8,900 | Brinell 150 | Plastic | Stainless Steel | 95335A627 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 8.7 | 8,900 | Brinell 150 | Plastic | Stainless Steel | 95335A628 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

10 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 12 | 13,900 | Brinell 150 | Plastic | Stainless Steel | 95335A629 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 12 | 13,900 | Brinell 150 | Plastic | Stainless Steel | 95335A631 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 12 | 13,900 | Brinell 150 | Plastic | Stainless Steel | 95335A632 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12 mm Diameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 14.5 | 20,000 | Brinell 150 | Plastic | Stainless Steel | 95335A633 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 40 | 14.5 | 20,000 | Brinell 150 | Plastic | Stainless Steel | 95335A634 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 14.5 | 20,000 | Brinell 150 | Plastic | Stainless Steel | 95335A635 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

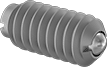

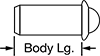

Ball-Nose Spring Plungers

|

|

Align, position, and lock moving parts for most machining and assembly tasks. These spring plungers have a spring-loaded ball that compresses when a part presses against it, and then pops out into a notch or groove to hold the part in place. Unlike long-nose spring plungers, the ball rolls easily in and out of position, so they're a great fit for applications that require consistent, smooth movement, such as positioning parts in an assembly line and aligning fixtures and jigs when cutting or drilling.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

440C Stainless Steel Nose—The strongest, most wear-resistant stainless steel noses, these grind against hard metal surfaces without denting or scratching. However, they are not as corrosion resistant as 316 stainless steel.

Nylon Nose—Extra soft to avoid scratching delicate surfaces. Nylon is best for use on soft materials, such as aluminum. It will swell and weaken when exposed to moisture, however, so it should only be used in dry environments.

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

440C Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.03" | 0.125" | 1 | 2.5 | Acetal | 0.53" | — | Slotted | 84775A42 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.03" | 0.125" | 2 | 5 | Acetal | 0.53" | — | Slotted | 84775A41 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.039" | 0.156" | 2 | 4.5 | Acetal | 0.58" | — | Slotted | 84775A44 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.039" | 0.156" | 4 | 9 | Acetal | 0.58" | — | Slotted | 84775A43 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.053" | 0.187" | 2.5 | 5 | Acetal | 0.63" | — | Slotted | 84775A46 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.053" | 0.187" | 5 | 10 | Acetal | 0.63" | — | Slotted | 84775A45 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-48 | 0.02" | 0.062" | 0.1 | 0.5 | 18-8 Stainless Steel | 0.19" | Spring Plunger Driver | Slotted | 34085A35 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4-48 | 0.02" | 0.062" | 0.1 | 0.5 | Steel | 0.19" | Spring Plunger Driver | Slotted | 84805A51 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 0.02" | 0.062" | 0.3 | 0.8 | 18-8 Stainless Steel | 0.25" | Spring Plunger Driver | Slotted | 34085A36 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5-40 | 0.02" | 0.062" | 0.3 | 0.8 | Steel | 0.25" | Spring Plunger Driver | Slotted | 84805A52 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-40 | 0.023" | 0.078" | 0.5 | 1 | 18-8 Stainless Steel | 0.31" | Spring Plunger Driver | Slotted | 34085A37 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-40 | 0.023" | 0.078" | 0.5 | 1 | Steel | 0.31" | Spring Plunger Driver | Slotted | 84805A53 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 0.025" | 0.094" | 0.5 | 1.3 | 18-8 Stainless Steel | 0.34" | Spring Plunger Driver | Slotted | 34085A5 | 0000 | 3382A12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-32 | 0.025" | 0.094" | 0.5 | 1.3 | Steel | 0.34" | Spring Plunger Driver | Slotted | 84805A54 | 0000 | 3382A12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | 18-8 Stainless Steel | 0.34" | Spring Plunger Driver | Slotted | 34085A38 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8-36 | 0.025" | 0.094" | 0.5 | 1.3 | Steel | 0.34" | Spring Plunger Driver | Slotted | 84805A55 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.51" | Spring Plunger Driver | Slotted | 34085A39 | 00000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 0.5 | 1.5 | Steel | 0.51" | Spring Plunger Driver | Slotted | 84805A63 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 1.5 | 3 | 18-8 Stainless Steel | 0.51" | Spring Plunger Driver | Slotted | 34085A41 | 00000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 1.5 | 3 | Steel | 0.51" | Spring Plunger Driver | Slotted | 84805A56 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 2 | 5 | 18-8 Stainless Steel | 0.51" | Spring Plunger Driver | Slotted | 34085A42 | 00000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10-32 | 0.025" | 0.094" | 2 | 5 | Steel | 0.51" | Spring Plunger Driver | Slotted | 84805A64 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.03" | 0.125" | 1 | 2.5 | Acetal | 0.53" | — | Slotted | 84775A52 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.03" | 0.125" | 2 | 5 | Acetal | 0.53" | — | Slotted | 84775A51 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 2 | 4 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | Slotted | 34085A43 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 2 | 4 | Steel | 0.53" | Spring Plunger Driver | Slotted | 84805A65 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 3 | 7 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | Slotted | 34085A44 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 3 | 7 | Steel | 0.53" | Spring Plunger Driver | Slotted | 84805A57 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 4 | 12 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | Slotted | 34085A45 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4"-20 | 0.035" | 0.125" | 4 | 12 | Steel | 0.53" | Spring Plunger Driver | Slotted | 84805A66 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.039" | 0.156" | 2 | 4.5 | Acetal | 0.58" | — | Slotted | 84775A56 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.039" | 0.156" | 4 | 9 | Acetal | 0.58" | — | Slotted | 84775A55 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 2 | 4.5 | 18-8 Stainless Steel | 0.58" | Spring Plunger Driver | Slotted | 34085A46 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 2 | 4.5 | Steel | 0.58" | Spring Plunger Driver | Slotted | 84805A67 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 4 | 9 | 18-8 Stainless Steel | 0.58" | Spring Plunger Driver | Slotted | 34085A47 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 4 | 9 | Steel | 0.58" | Spring Plunger Driver | Slotted | 84805A58 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 6 | 17 | 18-8 Stainless Steel | 0.58" | Spring Plunger Driver | Slotted | 34085A48 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 0.04" | 0.156" | 6 | 17 | Steel | 0.58" | Spring Plunger Driver | Slotted | 84805A68 | 0000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 2.5 | 5 | 18-8 Stainless Steel | 0.63" | Spring Plunger Driver | Slotted | 34085A49 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 2.5 | 5 | Steel | 0.63" | Spring Plunger Driver | Slotted | 84805A69 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 5 | 10 | 18-8 Stainless Steel | 0.63" | Spring Plunger Driver | Slotted | 34085A51 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 5 | 10 | Steel | 0.63" | Spring Plunger Driver | Slotted | 84805A59 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 6 | 21 | 18-8 Stainless Steel | 0.63" | Spring Plunger Driver | Slotted | 34085A52 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.048" | 0.188" | 6 | 21 | Steel | 0.63" | Spring Plunger Driver | Slotted | 84805A7 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.053" | 0.187" | 2.5 | 5 | Acetal | 0.63" | — | Slotted | 84775A54 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 0.053" | 0.187" | 5 | 10 | Acetal | 0.63" | — | Slotted | 84775A53 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 3 | 6 | 18-8 Stainless Steel | 0.75" | Spring Plunger Driver | Slotted | 34085A53 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 3 | 6 | Steel | 0.75" | Spring Plunger Driver | Slotted | 84805A71 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 6 | 12 | 18-8 Stainless Steel | 0.75" | Spring Plunger Driver | Slotted | 34085A54 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 6 | 12 | Steel | 0.75" | Spring Plunger Driver | Slotted | 84805A61 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 6 | 30 | 18-8 Stainless Steel | 0.75" | Spring Plunger Driver | Slotted | 34085A1 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 0.072" | 0.281" | 6 | 30 | Steel | 0.75" | Spring Plunger Driver | Slotted | 84805A72 | 0000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 4.5 | 9 | 18-8 Stainless Steel | 0.98" | Spring Plunger Driver | Slotted | 34085A2 | 00000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 4.5 | 9 | Steel | 0.98" | Spring Plunger Driver | Slotted | 84805A73 | 0000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 7 | 50 | 18-8 Stainless Steel | 0.98" | Spring Plunger Driver | Slotted | 34085A4 | 00000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 7 | 50 | Steel | 0.98" | Spring Plunger Driver | Slotted | 84805A74 | 0000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 9 | 18 | 18-8 Stainless Steel | 0.98" | Spring Plunger Driver | Slotted | 34085A3 | 00000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8"-11 | 0.096" | 0.375" | 9 | 18 | Steel | 0.98" | Spring Plunger Driver | Slotted | 84805A62 | 0000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 x 0.5 mm | 0.4 mm | 1.5 mm | 0.7 | 1 | 18-8 Stainless Steel | 7 mm | Spring Plunger Driver | Slotted | 2277A65 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 x 0.5 mm | 0.4 mm | 1.5 mm | 0.7 | 1 | Steel | 7 mm | Spring Plunger Driver | Slotted | 2191A25 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 x 0.7 mm | 0.8 mm | 2.5 mm | 0.9 | 2.3 | 18-8 Stainless Steel | 9 mm | Spring Plunger Driver | Slotted | 2277A51 | 00000 | 3382A12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 x 0.7 mm | 0.8 mm | 2.5 mm | 0.9 | 2.3 | Steel | 9 mm | Spring Plunger Driver | Slotted | 2191A11 | 0000 | 3382A12 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 x 0.8 mm | 0.9 mm | 3.5 mm | 1.8 | 3.2 | 18-8 Stainless Steel | 12 mm | Spring Plunger Driver | Slotted | 2277A66 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 x 0.8 mm | 0.9 mm | 3.5 mm | 1.8 | 3.2 | Steel | 12 mm | Spring Plunger Driver | Slotted | 2191A26 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 x 0.8 mm | 0.9 mm | 3.5 mm | 3.4 | 5 | 18-8 Stainless Steel | 12 mm | Spring Plunger Driver | Slotted | 2277A67 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 x 0.8 mm | 0.9 mm | 3.5 mm | 3.4 | 5 | Steel | 12 mm | Spring Plunger Driver | Slotted | 2191A27 | 0000 | 3382A13 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 0.5 | 1.4 | 18-8 Stainless Steel | 14 mm | Spring Plunger Driver | Slotted | 2277A53 | 00000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 0.5 | 1.4 | Steel | 14 mm | Spring Plunger Driver | Slotted | 2191A13 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 2 | 2.9 | 18-8 Stainless Steel | 14 mm | Spring Plunger Driver | Slotted | 2277A52 | 00000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 2 | 2.9 | Steel | 14 mm | Spring Plunger Driver | Slotted | 2191A12 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 6.3 | 9 | 18-8 Stainless Steel | 14 mm | Spring Plunger Driver | Slotted | 2277A54 | 00000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 x 1 mm | 1 mm | 3.5 mm | 6.3 | 9 | Steel | 14 mm | Spring Plunger Driver | Slotted | 2191A14 | 0000 | 3382A14 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 1.1 | 2.3 | 18-8 Stainless Steel | 16 mm | Spring Plunger Driver | Slotted | 2277A56 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 1.1 | 2.3 | Steel | 16 mm | Spring Plunger Driver | Slotted | 2191A16 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 3.4 | 6.7 | 18-8 Stainless Steel | 16 mm | Spring Plunger Driver | Slotted | 2277A55 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 3.4 | 6.7 | Steel | 16 mm | Spring Plunger Driver | Slotted | 2191A15 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 9 | 13.4 | 18-8 Stainless Steel | 16 mm | Spring Plunger Driver | Slotted | 2277A57 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 x 1.25 mm | 1.5 mm | 5 mm | 9 | 13.4 | Steel | 16 mm | Spring Plunger Driver | Slotted | 2191A17 | 00000 | 3382A15 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 1.8 | 3.4 | 18-8 Stainless Steel | 19 mm | Spring Plunger Driver | Slotted | 2277A59 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 1.8 | 3.4 | Steel | 19 mm | Spring Plunger Driver | Slotted | 2191A19 | 0000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 4.5 | 7.8 | 18-8 Stainless Steel | 19 mm | Spring Plunger Driver | Slotted | 2277A58 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 4.5 | 7.8 | Steel | 19 mm | Spring Plunger Driver | Slotted | 2191A18 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 13.4 | 20 | 18-8 Stainless Steel | 19 mm | Spring Plunger Driver | Slotted | 2277A61 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 x 1.5 mm | 2 mm | 6 mm | 13.4 | 20 | Steel | 19 mm | Spring Plunger Driver | Slotted | 2191A21 | 00000 | 3382A16 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 2.3 | 4.5 | 18-8 Stainless Steel | 22 mm | Spring Plunger Driver | Slotted | 2277A63 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 2.3 | 4.5 | Steel | 22 mm | Spring Plunger Driver | Slotted | 2191A23 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 6.7 | 12.3 | 18-8 Stainless Steel | 22 mm | Spring Plunger Driver | Slotted | 2277A62 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 6.7 | 12.3 | Steel | 22 mm | Spring Plunger Driver | Slotted | 2191A22 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 16.8 | 25.7 | 18-8 Stainless Steel | 22 mm | Spring Plunger Driver | Slotted | 2277A64 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 x 1.75 mm | 2.5 mm | 8 mm | 16.8 | 25.7 | Steel | 22 mm | Spring Plunger Driver | Slotted | 2191A24 | 00000 | 3382A17 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 3.5 mm | 10 mm | 9.2 | 19.3 | 18-8 Stainless Steel | 24 mm | Spring Plunger Driver | Slotted | 2277A68 | 0000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 3.5 mm | 10 mm | 9.2 | 19.3 | Steel | 24 mm | Spring Plunger Driver | Slotted | 2191A28 | 00000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 3.5 mm | 10 mm | 15.3 | 32 | 18-8 Stainless Steel | 24 mm | Spring Plunger Driver | Slotted | 2277A69 | 0000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M16 x 2 mm | 3.5 mm | 10 mm | 15.3 | 32 | Steel | 24 mm | Spring Plunger Driver | Slotted | 2191A29 | 00000 | 3382A18 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

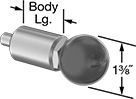

Ball-Grip Weld-On Retractable Spring Plungers

|

The smooth ball handle is easy to grip and won't catch on other parts. Pull it back to manually retract the nose and make adjustments whenever you need. Since they weld in place, these spring plungers have the strongest hold for aligning, securing, and positioning components on heavy machinery. They can do everything from locking attachments on forklifts and holding dies in place on industrial presses. To change your setup, unthread the spring plunger from the old welded-on barrel and thread it into a new one.

Zinc-Plated Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. They withstand occasional exposure to moisture.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Spring Plungers | Replacement Barrel Sleeves | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Body | Handle | Twist-to-Lock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extended Lg. | Dia. | Material | Wd. | Lg. | Material | Lg. | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.25" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A222 | 000000 | 90222A804 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A625 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A643 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 90222A679 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | Steel | 1" | 2.25" | Plastic | 1 3/8" | 90222A447 | 00000 | 90222A805 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.688" | 0.5" | Steel | 1" | 1.5" | Plastic | 1 3/8" | 90222A343 | 00000 | 90222A804 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.375" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 91712A443 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 1.5" | Plastic | 1 3/8" | 91712A461 | 00000 | 91712A582 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.5" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 91712A497 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.563" | 0.625" | 18-8 Stainless Steel | 1" | 2.25" | Plastic | 1 3/8" | 91712A321 | 00000 | 91712A583 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Press-Fit Ball-Nose Spring Plungers

|  |

Flanged Profile Smooth Body | Flanged Profile |

When you can't tap threads in your mounting surface, push these spring plungers into unthreaded holes. They work well in wood, plastic, and other soft materials that might crack if you try to cut threads. The spring-loaded ball compresses when a part presses against it, and then pops out into a notch or groove to hold the part in place.

For a snug fit, use an arbor press to install these spring plungers in a slightly smaller hole than the body diameter.

Flanged Profile—The flanged body stops the spring plunger from sliding back through the hole when the nose compresses under a strong force. It also acts as a gripping tab so you can pull the plunger out to make adjustments.

420 Stainless Steel Nose—Highly wear resistant, the nose grinds against hard metal surfaces without denting or scratching. However, 420 stainless steel is not quite as corrosion resistant as 316 stainless steel.

Acetal Nose—The best plastic for damp and wet environments, acetal won't swell or lose strength if exposed to moisture. These noses are extra soft to avoid scratching delicate surfaces. They are best for use on soft materials, such as aluminum.

Nylon Nose—Extra soft to avoid scratching delicate surfaces. Nylon is best for use on soft materials, such as aluminum. It will swell and weaken when exposed to moisture, however, so it should only be used in dry environments.

Smooth Body—These spring plungers slide effortlessly into unthreaded holes, but don't grip quite as firmly as those with a knurled body.

Nose | Nose Force, lbf | Body | Flange | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Extended Lg. | Dia. | Extended | Compressed | Material | Texture | Dia. | Lg. | Thick. | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Flanged Profile | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

420 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.55 mm | 2 mm | 0.4 | 0.8 | Acetal | Smooth | 3 mm | 3.4 mm | 0.6 mm | 3.6 mm | 4232N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 3 mm | 0.7 | 1.3 | Acetal | Smooth | 4 mm | 4 mm | 1 mm | 4.6 mm | 4232N12 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 4 mm | 1.3 | 2.1 | Acetal | Smooth | 5 mm | 5 mm | 1 mm | 5.6 mm | 4232N13 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm | 5 mm | 1.4 | 2.8 | Acetal | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 4232N14 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9 mm | 6.5 mm | 2.2 | 4.6 | Acetal | Smooth | 8 mm | 8 mm | 1 mm | 8.5 mm | 4232N15 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 8 mm | 2.7 | 5 | Acetal | Smooth | 10 mm | 12 mm | 1.5 mm | 11 mm | 4232N16 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 10 mm | 3.1 | 5.6 | Acetal | Smooth | 12 mm | 14.5 mm | 1.5 mm | 13 mm | 4232N17 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A41 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.093" | 2 | 5 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A7 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 0.8 | 2 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 8483A79 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 8483A8 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 1.5 | 3.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 8483A78 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | 18-8 Stainless Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 8483A77 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.046" | 0.125" | 3 | 7.5 | Steel | Smooth | 0.157" | 0.33" | 1/32" | 3/16" | 8483A76 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 8483A42 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 4 | 10 | Steel | Smooth | 0.188" | 0.41" | 1/32" | 1/4" | 8483A71 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | 18-8 Stainless Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 8483A43 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 6 | 13 | Steel | Smooth | 0.25" | 0.48" | 3/64" | 5/16" | 8483A72 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A44 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 8 | 16 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A73 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A45 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 10 | 18 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A74 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | 18-8 Stainless Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 8483A46 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 12 | 23 | Steel | Smooth | 0.5" | 1.13" | 3/32" | 11/16" | 8483A75 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.8 mm | 3 mm | 0.7 | 1.5 | Acetal | Smooth | 4 mm | 4 mm | 1 mm | 4.6 mm | 4232N18 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 mm | 4 mm | 1.3 | 2.1 | Acetal | Smooth | 5 mm | 5 mm | 1 mm | 5.6 mm | 4232N19 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.6 mm | 5 mm | 1.4 | 2.8 | Acetal | Smooth | 6 mm | 6 mm | 1 mm | 6.5 mm | 4232N21 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1.9 mm | 6.5 mm | 2.2 | 4.6 | Acetal | Smooth | 8 mm | 8 mm | 1 mm | 8.5 mm | 4232N22 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.4 mm | 8 mm | 2.7 | 5 | Acetal | Smooth | 10 mm | 12 mm | 1.5 mm | 11 mm | 4232N23 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 10 mm | 3.1 | 5.6 | Acetal | Smooth | 12 mm | 14.5 mm | 1.5 mm | 13 mm | 4232N24 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A24 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.4 | 1.3 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A57 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | 18-8 Stainless Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A25 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.035" | 0.094" | 0.8 | 2.5 | Steel | Smooth | 0.125" | 0.25" | 1/32" | 3/16" | 8483A51 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 8483A26 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 1 | 2.5 | Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 8483A58 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 8483A27 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.058" | 0.156" | 2 | 5 | Steel | Smooth | 0.188" | 0.39" | 3/64" | 1/4" | 8483A52 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 8483A28 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 1.5 | 3.5 | Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 8483A59 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | 18-8 Stainless Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 8483A29 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.07" | 0.187" | 3 | 7 | Steel | Smooth | 0.25" | 0.47" | 3/64" | 5/16" | 8483A53 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A31 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 2 | 5 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A61 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | 18-8 Stainless Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A32 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.09" | 0.25" | 4 | 10 | Steel | Smooth | 0.312" | 0.64" | 3/64" | 3/8" | 8483A54 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A33 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 2.5 | 7 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A62 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | 18-8 Stainless Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A34 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.11" | 0.312" | 5 | 14 | Steel | Smooth | 0.375" | 0.79" | 5/64" | 1/2" | 8483A55 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 8483A35 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 4 | 9 | Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 8483A63 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | 18-8 Stainless Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 8483A36 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.161" | 0.437" | 8 | 18 | Steel | Smooth | 0.5" | 1.1" | 7/64" | 11/16" | 8483A56 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||