About Flanged Flow-Adjustment Valves

More

About On/Off Valves

More

High-Pressure Compact Threaded On/Off Valves

These valves handle twice the pressure of other compact valves. Install them in tight spots, such as where pipelines are crowded together. They’re roughly half the height and length of standard threaded valves.

316 stainless steel valves resist corrosion better than brass and steel valves.

Standard-port valves slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating | Port Type | End-to-End Lg. | Each | |

NPT Female × NPT Female | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/4 × 1/4 | 1.3 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2" | 00000000 | 000000 |

| 3/8 × 3/8 | 2.6 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 3/8" | 00000000 | 00000 |

| 1/2 × 1/2 | 9.2 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 15/16" | 00000000 | 00000 |

| 3/4 × 3/4 | 12.6 | 2000 psi @ 100° F | -30° to 400° | Not Rated | Standard | 2 5/16" | 00000000 | 00000 |

On/Off Valves with Yor-Lok Fittings

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Valves are standard port, so they slightly restrict flow.

316 stainless steel valves are more corrosion resistant than plain and nickel-plated brass valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Ball

- For Use With: Air, Argon, Helium, Krypton, Neon, Oil, Water, Xenon

- Seal Material: PTFE Plastic

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | Each | |

Yor Lok × Yor Lok | ||||||

|---|---|---|---|---|---|---|

| 1/4" | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 000000 |

| 3/8" | 2.5 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 0000000 | 00000 |

| 1/2" | 9.25 | 2000 psi @ 100° F | -30° to 400° | 3 3/4" | 0000000 | 000000 |

| 3/4" | 12.65 | 2000 psi @ 100° F | -30° to 400° | 4 7/16" | 00000000 | 000000 |

| 1" | 17.35 | 2000 psi @ 100° F | -30° to 400° | 5 1/8" | 00000000 | 000000 |

| 6mm | 1.25 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 00000 |

| 8mm | 1.35 | 2000 psi @ 100° F | -30° to 400° | 3 9/16" | 00000000 | 000000 |

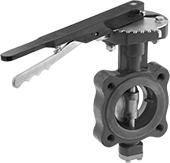

Flow-Adjustment Valves with Grooved-End Fittings

- Valve Type: Butterfly

- For Use With: Water

- Specifications Met: MSS-SP-67

Commonly used in water service pipelines and HVAC systems, these valves have grooved ends that connect to pipe with a clamp (not included) for easy installation. Since there’s no heat or threading required, they provide quick access to your pipeline for routine maintenance. All gradually open and close to adjust and regulate flow. Valves have 10 flow-adjustment positions. Fix the lockable lever handle in place using a padlock (not included) with a shackle diameter up to 5/16”.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Overall | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | For Max. Shackle Dia. | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, ° F | End-to-End Lg. | Ht. | Lg. | Each | |

Polyamide-Coated Ductile Iron Body | |||||||||

Grooved End × Grooved End | |||||||||

| 2 | 5/16" | 195 | 300 psi @ 70° F | -20° to 200° | 3 5/16" | 8 3/16" | 12 7/8" | 0000000 | 0000000 |

| 3 | 5/16" | Not Rated | 300 psi @ 70° F | -20° to 200° | 3 7/8" | 9" | 12 7/8" | 0000000 | 000000 |

| 4 | 5/16" | 930 | 300 psi @ 70° F | -20° to 200° | 4 9/16" | 10 3/4" | 13" | 0000000 | 000000 |

| 6 | 5/16" | Not Rated | 300 psi @ 70° F | -20° to 200° | 5 7/8" | 14 1/16" | 17 3/8" | 0000000 | 000000 |

Plastic Flanged Flow-Adjustment Valves

- Valve Type: Butterfly

- For Use With: Water, Oil

Often used in low-pressure water pipelines, these valves have a plastic body for the lightest weight of our flanged flow-adjustment valves. Bolt them to flanges for adjusting and regulating flow in flanged pipelines. Fix the lockable lever handle in place using a padlock (not included) with a shackle diameter up to 3/16”. Valves are wafer style, so they must be sandwiched between two flanges. They have unthreaded holes that do not match the ANSI flange pattern; use two of the four holes to align the valve between the flanges.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

PVC Plastic Body—PVC Plastic Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 3/16" | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 249 | 150 psi @ 70° F | 40° to 140° | 1 15/16" | 0000000 | 0000000 |

| 4 | 3/16" | 125, 150 | 9" | 7 1/2" | 4 | 3/4" | No | 413 | 150 psi @ 70° F | 40° to 140° | 2 1/4" | 0000000 | 000000 |

| 6 | 3/16" | 125, 150 | 11" | 9 1/2" | 4 | 0.88" | No | 1,309 | 150 psi @ 70° F | 40° to 140° | 2 13/16" | 0000000 | 000000 |

Plastic Flanged Flow-Adjustment Valves for Chemicals

- Valve Type: Butterfly

- For Use With: Water, Carbon Dioxide, Citric Acid, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Phosphoric Acid, Salt Water

- Seat Material: Fluoroelastomer Rubber

- Specifications Met: FM Approved

In addition to fluoroelastomer seats that resist a wide range of chemicals, these valves have no metal parts to corrode, so they’re often used for chemical-processing applications in corrosive conditions. All bolt to flanges for adjusting and regulating flow in flanged pipelines. Fix the lockable lever handle in place using a padlock (not included) with a shackle diameter up to 7/16”. Valves are wafer style, so they must be sandwiched between two flanges; all have unthreaded holes to help align the valve between the flanges.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

PVC Plastic Body—PVC Plastic Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 7/16" | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 109 | 150 psi @ 70° F | 40° to 140° | 1 15/16" | 0000000 | 0000000 |

| 3 | 7/16" | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 345 | 150 psi @ 70° F | 40° to 140° | 2 1/8" | 0000000 | 000000 |

| 4 | 7/16" | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 411 | 150 psi @ 70° F | 40° to 140° | 2 9/32" | 0000000 | 00000000 |

| 6 | 7/16" | 125, 150 | 11" | 9 1/2" | 8 | 7/8" | No | 1,125 | 150 psi @ 70° F | 40° to 140° | 2 3/4" | 0000000 | 00000000 |

CPVC Plastic Body—CPVC Plastic Disc | |||||||||||||

| 2 | 7/16" | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 109 | 150 psi @ 70° F | 40° to 200° | 1 15/16" | 0000000 | 00000000 |

| 3 | 7/16" | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 345 | 150 psi @ 70° F | 40° to 200° | 2 1/8" | 0000000 | 00000000 |

| 4 | 7/16" | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 411 | 150 psi @ 70° F | 40° to 200° | 2 9/32" | 0000000 | 00000000 |

| 6 | 7/16" | 125, 150 | 11" | 9 1/2" | 8 | 7/8" | No | 1,125 | 150 psi @ 70° F | 40° to 200° | 2 3/4" | 0000000 | 00000000 |

Flanged Flow-Adjustment Valves for Steam

- Valve Type: Butterfly

- For Use With: Steam

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.34A

Rated for steam pressures up to 100 psi @ 400° F, these valves have PTFE seats for excellent temperature resistance. They bolt to flanges for adjusting and regulating flow in flanged pipelines. These valves are lug style, so they can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Powder-Coated Epoxy Carbon Steel Body | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Powder-Coated Epoxy CF8M Stainless Steel Disc | ||||||||||||

| 2 | 150 | 6" | 4 3/4" | 4 | 3/4" | No | 92 | 100 psi @ 400° F | -20° to 450° | 1 11/16" | 000000 | 000000000 |

| 3 | 150 | 7 1/2" | 6" | 4 | 3/4" | No | 260 | 100 psi @ 400° F | -20° to 450° | 1 7/8" | 000000 | 00000000 |

Flanged Flow-Adjustment Valves for Drinking Water

- Valve Type: Butterfly

- For Use With: Drinking Water

- Specifications Met: FM Approved, NSF/ANSI 61

These valves meet NSF/ANSI 61 for use with drinking water. They bolt to flanges for adjusting and regulating flow in flanged pipelines. All have seven flow-adjustment positions. The lockable lever handle can be fixed in place using a padlock (not included) with a shackle diameter up to 7/16”. Valves are wafer style, so they must be sandwiched between two flanges; all have unthreaded holes to help align the valve between the flanges.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Max. Shackle Dia. | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

PVC Plastic Body—PVC Plastic Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 7/16" | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 109 | 150 psi @ 70° F | 40° to 140° | 1 15/16" | 0000000 | 0000000 |

| 3 | 7/16" | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 345 | 150 psi @ 70° F | 40° to 140° | 2 1/8" | 0000000 | 000000 |

| 4 | 7/16" | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 411 | 150 psi @ 70° F | 40° to 140° | 2 9/32" | 0000000 | 000000 |

| 6 | 7/16" | 125, 150 | 11" | 9 1/2" | 8 | 7/8" | No | 1,125 | 150 psi @ 70° F | 40° to 140° | 2 3/4" | 0000000 | 000000 |

CPVC Plastic Body—CPVC Plastic Disc | |||||||||||||

| 2 | 7/16" | 125, 150 | 6" | 4 3/4" | 4 | 3/4" | No | 109 | 150 psi @ 70° F | 40° to 200° | 1 15/16" | 0000000 | 000000 |

| 3 | 7/16" | 125, 150 | 7 1/2" | 6" | 4 | 3/4" | No | 345 | 150 psi @ 70° F | 40° to 200° | 2 1/8" | 0000000 | 000000 |

| 4 | 7/16" | 125, 150 | 9" | 7 1/2" | 8 | 3/4" | No | 411 | 150 psi @ 70° F | 40° to 200° | 2 9/32" | 0000000 | 000000 |

| 6 | 7/16" | 125, 150 | 11" | 9 1/2" | 8 | 7/8" | No | 1,125 | 150 psi @ 70° F | 40° to 200° | 2 3/4" | 0000000 | 00000000 |