Filter by

Shape

Material

Backing Type

Color

Form

Maximum Temperature

System of Measurement

Performance

Construction

REACH

RoHS

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Sold As

Specifications Met

Minimum Temperature

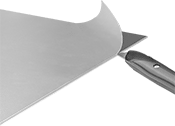

Peel-Away Multilayer Shim Stock

|

Fine-tune thickness without worrying about stacking multiple shims. Cut the shim stock into custom shapes that suit your needs. It's made of layers of material bonded with adhesive—peel off the layers with a utility knife until you reach your desired thickness. To make peeling easier, warm the created shims to soften the adhesive. With thickness tolerances as fine as a strand of hair, the shims will precisely align, space, and level components on dies, presses, and machinery.

Polyimide—Originally designed for military aircraft, it’s used in everything from aerospace to electronics where weight, electrical insulation, and precision are vital.

Certificate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thk. | Thk. Tolerance | No. of Layers | Layer Thk. | Type | Form | Specs. Met | Form | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyimide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12" Wide × 12" Long | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.008" | -0.0005" to 0.001" | 2 | 0.004" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N11 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.01" | -0.001" to 0.0015" | 5 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.016" | -0.001" to 0.0015" | 8 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N13 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.02" | -0.001" to 0.002" | 10 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N14 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.032" | -0.002" to 0.003" | 16 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.048" | -0.002" to 0.005" | 23 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.062" | -0.002" to 0.006" | 30 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.094" | -0.003" to 0.009" | 46 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.124" | -0.003" to 0.012" | 61 | 0.002" | Material Certificate | Paper | ASTM D5213, SAE AMS-DTL-22499 | Sheet | 3126N19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||