Filter by

Material

Material Grade

Thickness

Color

Inside Width

Performance

Flexibility

Inside Height

DFARS Specialty Metals

Finish

Square Head Material

Head Material

Face Material

Housing Material

Raw Materials

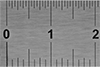

Measuring and Inspecting

Fastening and Joining

Fabricating and Machining