Filter by

Attachment Type

Diameter

Material

Wire Rope Construction

Weight Capacity

REACH

RoHS

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Specifications Met

Body Material

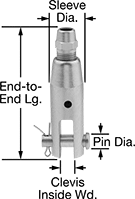

Clevis-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Steel | Zinc-Plated Steel | 316 Stainless Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-End Lg. | Clevis Inside Wd. | Sleeve Dia. | Pin Dia. | Wt. Cap., lb. | Specs. Met | Each | Each | Each | ||||

| 3/64" to 1/16" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/16" | 3/16" | 1/2" | 3/16" | 90 | ASME B30.26 ASME B30.9 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

| 5/64" to 3/32" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 5/8" | 1/4" | 100 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/2" | 1/4" | 5/8" | 1/4" | 300 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/8" | 5/16" | 3/4" | 5/16" | 700 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 3/4" | 3/8" | 15/16" | 3/8" | 1,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 13/16" | 7/16" | 1 3/16" | 1/2" | 3,000 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

Stud-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Thread | Steel | Zinc-Plated Steel | 316 Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Overall Lg. | Size | Lg. | Sleeve Dia. | Wt. Cap., lb. | Specs. Met | Each | Each | Each | ||||

| 3/64" to 1/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/16" | 10-32 | 1 9/16" | 1/2" | 90 | ASME B30.26 ASME B30.9 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

| 5/64" to 3/32" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/2" | 1/4"-28 | 1 7/8" | 9/16" | 100 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/2" | 1/4"-28 | 1 7/8" | 9/16" | 300 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 1/8" | 1/4"-20 | 2 1/2" | 5/8" | 300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 3/16" | 3/8"-24 | 2 3/16" | 3/4" | 700 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 6 5/16" | 3/8"-16 | 4 1/8" | 3/4" | 700 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 7 1/16" | 1/2"-20 | 4 9/16" | 7/8" | 1,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 8" | 1/2"-13 | 5" | 1" | 1,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 8 3/16" | 3/4"-16 | 4 15/16" | 1 1/8" | 3,000 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 8 1/4" | 5/8"-11 | 4 1/2" | 1 1/8" | 3,000 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

| 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 10 15/16" | 3/4"-10 | 6 3/8" | 1 1/2" | 5,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

| 1/2" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 11" | 7/8"-14 | 6 15/16" | 1 7/16" | 5,300 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

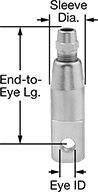

Eye-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Eye | Steel | Zinc-Plated Steel | 316 Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | End-to-Eye Lg. | ID | Thk. | Sleeve Dia. | Wt. Cap., lb. | Specs. Met | Each | Each | Each | ||||

| 3/64" to 1/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 25/32" | 3/16" | 3/16" | 1/2" | 90 | ASME B30.26 ASME B30.9 | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | |

| 5/64" to 3/32" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/8" | 1/4" | 1/4" | 5/8" | 100 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 1/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 1/8" | 1/4" | 1/4" | 5/8" | 300 | ASME B30.26 ASME B30.9 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | |

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 2 19/32" | 5/16" | 5/16" | 3/4" | 600 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3 1/4" | 3/8" | 3/8" | 15/16" | 1,100 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 36 Fiber Core 6 × 36 Strand Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 4 7/32" | 1/2" | 7/16" | 1 3/16" | 2,600 | ASME B30.26 ASME B30.9 | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | |

Closed-Body Clevis-to-Wire Rope Turnbuckles—For Lifting

Steel Body with Steel Fittings

Clevis Pin | For Wire Rope | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Retracted Lg. | Max. Adjustment | Extended Lg. | Dia. | Closure Method | Clevis Inside Wd. | Thread Size | Dia. | Construction | Wire Rope Fitting Type | Specs. Met | Each | |||

| 90 | 6 5/16" | 2 1/2" | 8 13/16" | 3/16" | Cotter Pin | 3/16" | 10-32 | 1/16" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 000000 | ||

| 340 | 7 11/16" | 2 7/8" | 10 9/16" | 1/4" | Cotter Pin | 1/4" | 1/4"-28 | 1/8" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 00000 | ||

| 740 | 9 1/2" | 3 1/8" | 12 5/8" | 5/16" | Cotter Pin | 5/16" | 3/8"-24 | 3/16" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 000000 | ||

| 1,360 | 10 15/16" | 4 13/16" | 15 3/4" | 3/8" | Cotter Pin | 3/8" | 1/2"-20 | 1/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 000000 | ||

Zinc-Plated Steel Body with Steel Fittings

Clevis Pin | For Wire Rope | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Retracted Lg. | Max. Adjustment | Extended Lg. | Dia. | Closure Method | Clevis Inside Wd. | Thread Size | Dia. | Construction | Wire Rope Fitting Type | Specs. Met | Each | |||

| 740 | 9 1/2" | 3 1/8" | 12 5/8" | 5/16" | Cotter Pin | 5/16" | 3/8"-24 | 3/16" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 0000000 | ||

| 3,020 | 13 1/4" | 5 5/16" | 18 9/16" | 1/2" | Cotter Pin | 7/16" | 3/4"-16 | 3/8" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 000000 | ||

316 Stainless Steel Body with Steel Fittings

Clevis Pin | For Wire Rope | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Retracted Lg. | Max. Adjustment | Extended Lg. | Dia. | Closure Method | Clevis Inside Wd. | Thread Size | Dia. | Construction | Wire Rope Fitting Type | Specs. Met | Each | |||

| 740 | 9 1/2" | 3 1/8" | 12 5/8" | 5/16" | Cotter Pin | 5/16" | 3/8"-24 | 3/16" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 0000000 | ||

| 1,360 | 10 15/16" | 4 13/16" | 15 3/4" | 3/8" | Cotter Pin | 3/8" | 1/2"-20 | 1/4" | 6 × 7 Fiber Core 6 × 19 IWRC 6 × 19 Fiber Core 6 × 26 IWRC 6 × 37 IWRC 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | Plug Lock | ASME B30.26 | 0000000 | 000000 | ||

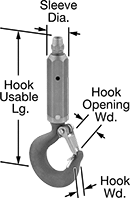

Swivel-Hook-End Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | Hook | Steel | Zinc-Plated Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Construction | Sleeve Dia. | Usable Lg. | Opening Wd. | Wd. | Fabrication | Material | Wt. Cap., lb. | Specs. Met | Each | Each | |||

| 3/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 3/4" | 5 31/32" | 1" | 9/16" | Forged | Steel | 665 | ASME B30.26 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 6 27/32" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | ——— | 0 | 0000000 | 000000 | |

| 1/4" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 7/16" | 1 1/16" | 5/8" | Forged | Steel | 1,175 | ASME B30.26 | 0000000 | 000000 | ——— | 0 | |

| 5/16" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 15/16" | 7 19/32" | 1 1/8" | 3/4" | Forged | Steel | 1,830 | ASME B30.26 | ——— | 0 | 0000000 | 000000 | |

| 3/8" | 6 × 19 Fiber Core 6 × 19 IWRC 6 × 26 IWRC 6 × 37 IWRC 6 × 7 Fiber Core 7 × 7 Strand Core 7 × 19 IWRC 7 × 19 Strand Core | 1 1/8" | 8 17/32" | 1 1/4" | 27/32" | Forged | Steel | 2,620 | ASME B30.26 | 0000000 | 000000 | 0000000 | 000000 | |

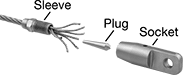

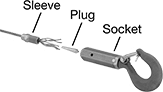

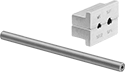

Plugs for Plug-Lock Wire Rope End Fittings—For Lifting

For Wire Rope | |||||

|---|---|---|---|---|---|

Dia. | Construction | Material | Each | ||

| 1/16" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 3/32" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 0000 | |

| 1/8" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 0000 | |

| 5/32" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 0000 | |

| 3/16" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 7/32" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 1/4" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 9/32" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 3/8" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |

| 1/2" | 6 × 19 IWRC, 6 × 19 Fiber Core, 7 × 7 Strand Core, 7 × 19 IWRC, 7 × 19 Strand Core | Brass | 0000000 | 00000 | |