Filter by

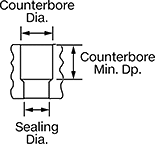

Counterbore Diameter

Sealing Diameter

Sleeve Material

Plug Connection Method

For Use With

Ball Material

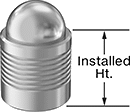

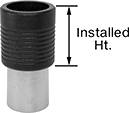

Installed Height

Minimum Counterbore Depth

Maximum Temperature

Shape

For Hole Type

DFARS Specialty Metals

Pin Material

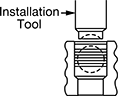

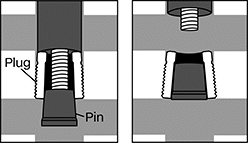

Push-In Bore Sealing Plugs

Counterbore | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Sealing Dia. | Dia. | Min. Dp. | Installed Ht. | Max. Pressure, psi | Max. Temp., ° F | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.113" | 1/8" | 2,100 | 300 | 5 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.149" | 5/32" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.17" | 3/16" | 2,100 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.208" | 7/32" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.17" | 3/16" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.208" | 7/32" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.196" | 7/32" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.247" | 1/4" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 0.233" | 1/4" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 0.287" | 19/64" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.255" | 9/32" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.326" | 21/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.275" | 5/16" | 2,100 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.385" | 25/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/32" | 3/8" | 0.385" | 25/64" | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.308" | 23/64" | 2,100 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.425" | 7/16" | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.3 mm | 3 mm | 2.9 mm | 3.18 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.2 mm | 7 mm | 7.3 mm | 7.5 mm | 3,000 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.2 mm | 10 mm | 10.8 mm | 11 mm | 3,000 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 mm | 12 mm | 12.8 mm | 13 mm | 1,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.2 mm | 3 mm | 3.4 mm | 3.6 mm | 4,600 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.3 mm | 5 mm | 5.3 mm | 5.5 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 4,600 | 300 | 5 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.4 mm | 7 mm | 7.3 mm | 7.5 mm | 4,600 | 300 | 5 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.4 mm | 8 mm | 8.3 mm | 8.5 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.4 mm | 9 mm | 9.8 mm | 10 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.4 mm | 10 mm | 10.8 mm | 11 mm | 4,600 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10.6 mm | 12 mm | 12.8 mm | 13 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12.7 mm | 14 mm | 14.5 mm | 15 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14.7 mm | 16 mm | 16.5 mm | 17 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16.7 mm | 18 mm | 18.5 mm | 19 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18.7 mm | 20 mm | 21.5 mm | 22 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20.7 mm | 22 mm | 24.5 mm | 25 mm | 3,600 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/16" | 3/32" | 0.081" | 3/32" | 5,500 | 300 | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/32" | 1/8" | 0.113" | 1/8" | 5,500 | 300 | 5 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8" | 5/32" | 0.13" | 5/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/32" | 3/16" | 0.152" | 13/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 7/32" | 0.187" | 7/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/32" | 1/4" | 0.212" | 17/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 9/32" | 1/4" | 9/32" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/32" | 5/16" | 0.327" | 21/64" | 5,500 | 300 | 5 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 11/32" | 0.385" | 25/64" | 5,500 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11/32" | 3/8" | 0.425" | 25/64" | 5,500 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 13/32" | 0.425" | 7/16" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/32" | 7/16" | 0.503" | 33/64" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 15/32" | 0.504" | 33/64" | 4,000 | 300 | 1 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2.2 mm | 3 mm | 3.4 mm | 3.6 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3.3 mm | 4 mm | 3.8 mm | 4 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.3 mm | 5 mm | 5.3 mm | 5.5 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5.3 mm | 6 mm | 6.3 mm | 6.5 mm | 5,500 | 300 | 1 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6.4 mm | 7 mm | 7.3 mm | 7.5 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7.4 mm | 8 mm | 8.3 mm | 8.5 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8.4 mm | 9 mm | 9.8 mm | 10 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9.4 mm | 10 mm | 10.8 mm | 11 mm | 5,500 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10.6 mm | 12 mm | 12.8 mm | 13 mm | 4,100 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12.7 mm | 14 mm | 14.5 mm | 15 mm | 4,100 | 300 | 1 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld-On Sights

316L Stainless Steel with Glass Window

For Hole Dia. | OD | Window Dia. | Max. Pressure @ Temp. | Temp. Range, ° F | For Use With | Seal Material | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

With Screw-Together Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 3 5/8" | 2" | 150 psi @ 70° F | -20 to 390 | Water, Hydraulic Fluid, Compressed Air | Silicone Rubber | DIN 11851 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 4 7/16" | 2 1/2" | 150 psi @ 70° F | -20 to 390 | Water, Hydraulic Fluid, Compressed Air | Silicone Rubber | DIN 11851 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 1/8" | 5" | 3 1/8" | 150 psi @ 70° F | -20 to 390 | Water, Hydraulic Fluid, Compressed Air | Silicone Rubber | DIN 11851 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 5 13/16" | 4" | 150 psi @ 70° F | -20 to 390 | Water, Hydraulic Fluid, Compressed Air | Silicone Rubber | DIN 11851 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | 7" | 5" | 90 psi @ 70° F | -20 to 390 | Water, Hydraulic Fluid, Compressed Air | Silicone Rubber | DIN 11851 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

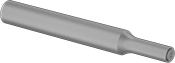

Pull-Through Bore Sealing Plugs

|  |

Sealing Dia. | Installed Ht. | Max. Pressure, psi | Max. Temp., ° F | Thread Size | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/64" | 11/64" | 2,000 | 300 | 4-40 | 5 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 mm | 5 mm | 2,000 | 300 | M3 × 0.5 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 6.5 mm | 2,000 | 300 | M4 × 0.7 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 6.5 mm | 2,000 | 300 | M5 × 0.8 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel Sleeve | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13/64" | 7/32" | 4,500 | 300 | 4-40 | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15/64" | 1/4" | 4,500 | 300 | 6-32 | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4.5 mm | 4 mm | 4,500 | 300 | M2 × 0.4 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 8.5 mm | 4,500 | 300 | M4 × 0.7 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 10.5 mm | 4,500 | 300 | M6 × 1 mm | 5 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sights for Quick-Clamp Sanitary Tube Fittings

304 Stainless Steel with Plastic Window

Temperature Range | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | For Flange OD | Window Dia. | Max. Pressure @ Temp. | Min. | Max., ° F | For Use With | Features | Specs. Met | Each | ||

| 1" | 1.98" | 1 1/4" | 150 psi @ 70° F | Not Rated | 200 | Water, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | With One-Piece Construction | ASME BPE | 0000000 | 0000000 | |

| 2" | 2.52" | 1 3/4" | 150 psi @ 70° F | Not Rated | 200 | Water, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | With One-Piece Construction | ASME BPE | 0000000 | 000000 | |

| 4" | 4.68" | 3 1/4" | 30 psi @ 70° F | Not Rated | 200 | Water, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Compressed Air, Salt Water, Steam | With One-Piece Construction | ASME BPE | 0000000 | 000000 | |

2205 Stainless Steel with Glass Window

For Tube OD | For Flange OD | Window Dia. | Max. Pressure @ Temp. | Temp. Range, ° F | For Use With | Specs. Met | Certification | USP Class | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

With One-Piece Construction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1", 1 1/2" | 1.98" | 1" | 230 psi @ 70° F | -40 to 500 | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | ASME BPE, ASTM A479, DIN 7079, DIN 7080 | TUV Rheinland Certified | VI | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 2.52" | 1 3/16" | 230 psi @ 70° F | -40 to 500 | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | ASME BPE, ASTM A479, DIN 7079, DIN 7080 | TUV Rheinland Certified | VI | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 3.58" | 1 1/2" | 150 psi @ 70° F | -40 to 500 | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | ASME BPE, ASTM A479, DIN 7079, DIN 7080 | TUV Rheinland Certified | VI | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 4.68" | 2 3/16" | 150 psi @ 70° F | -40 to 500 | Water, Hydraulic Fluid, Diesel Fuel, Acetic Acid (White Vinegar), Air, Alcohol-Based Solvents, Beverage, Chemicals, Compressed Air, Food, Fuel Oil, Gasoline, Inert Gas, Ketone, Oil, Salt Water, Steam | ASME BPE, ASTM A479, DIN 7079, DIN 7080 | TUV Rheinland Certified | VI | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||