Filter by

Thread Size

Nose Material

Body Material

Body Finish

Locking Type

Plunger Locking Type

System of Measurement

Handle Material

Compressed Nose Force

Extended Nose Force

Mount Type

Thread Type

Thread Spacing

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Performance

Drive Style

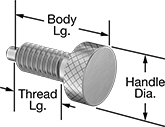

Knob-Grip Retractable Spring Plungers

|

With the most versatile handle we offer, these fit in tight spaces while still giving you something to grab. A tug retracts the nose so you can make controlled adjustments. Use these spring plungers for everything from positioning workpieces to changing the height of tables and platforms.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

316 Stainless Steel Nose—With the best corrosion resistance of all, 316 stainless steel stands up to harsh weather, salt water, and chemicals. The nose is strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Brass Nose—Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments. Since brass is softer than other metals, these noses are less likely to dent surfaces, however, they could deform under high stress.

Acetal Nose—The best plastic for damp and wet environments, acetal won't swell or lose strength if exposed to moisture. These noses are extra soft to avoid scratching delicate surfaces. They are best for use on soft materials, such as aluminum.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Nose | Nose Force, lbf | Body | Handle | Nonlocking | Twist-to-Lock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Material | Dia. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | Black-Oxide Steel | 2.15" | Steel | 1 1/2" | ——— | 0 | 8497A77 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | Zinc-Plated Steel | 2.15" | Steel | 1 1/2" | ——— | 0 | 84915A779 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.2" | 0.45" | 0.375" | 1.5 | 16 | Zinc-Plated Steel | 2" | Steel | 1 1/2" | 84915A82 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | 18-8 Stainless Steel | 2.15" | 18-8 Stainless Steel | 1 1/2" | ——— | 0 | 84935A51 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | 316 Stainless Steel | 2.15" | 316 Stainless Steel | 1 1/2" | ——— | 0 | 8692A27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.2" | 0.45" | 0.375" | 1.5 | 16 | 316 Stainless Steel | 2.01" | 316 Stainless Steel | 1 1/2" | 8692A17 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1" | 0.45" | 0.375" | 1.5 | 16 | Brass | 2.01" | Brass | 1 1/2" | 8471A62 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | Brass | 2.15" | Brass | 1 1/2" | ——— | 0 | 8471A23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.2" | 0.45" | 0.375" | 1.5 | 16 | Brass | 2.01" | Brass | 1 1/2" | 8471A29 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1.13" | 0.45" | 0.375" | 1.5 | 16 | 18-8 Stainless Steel | 2.15" | 18-8 Stainless Steel | 1 1/2" | ——— | 0 | 2369A47 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

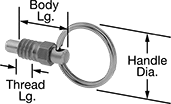

Ring-Grip Retractable Spring Plungers

|

Spring Plunger |

Loop a lanyard through the ring to secure these spring plungers to machinery and prevent accidental drops. Pull the ring back to manually retract the nose and position, align, and lock components as needed for your job.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

316 Stainless Steel Nose—With the best corrosion resistance of all, 316 stainless steel stands up to harsh weather, salt water, and chemicals. The nose is strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Brass Nose—Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments. Since brass is softer than other metals, these noses are less likely to dent surfaces, however, they could deform under high stress.

Twist-to-Lock—Free up both hands to adjust your workpiece or switch out parts without the plunger springing back and getting in the way. Pull back the handle and twist to lock the nose in its retracted position.

Nose | Nose Force, lbf | Body | Handle | Nonlocking | Twist-to-Lock | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Thread Lg. | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Material | Dia. | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.88" | 0.5" | 0.437" | 1.5 | 6 | Zinc-Plated Steel | 1.5" | Steel | 1 1/8" | 8487A76 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.88" | 0.5" | 0.437" | 1.5 | 6 | 18-8 Stainless Steel | 1.5" | 18-8 Stainless Steel | 1 1/8" | 8500A56 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.88" | 0.5" | 0.437" | 1.5 | 6 | 316 Stainless Steel | 1.5" | 316 Stainless Steel | 1 1/8" | 8691A36 | 00000 | 8691A44 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2.69" | 0.65" | 0.43" | 5 | 10 | 316 Stainless Steel | 4.06" | 316 Stainless Steel | 1.4" | 8691A52 | 00000 | 8691A59 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.88" | 0.5" | 0.437" | 1.5 | 6 | Brass | 1.5" | Steel | 1 1/8" | 8482A35 | 00000 | 8482A75 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 2.69" | 0.65" | 0.43" | 5 | 10 | Brass | 4.06" | Steel | 1.4" | 8482A45 | 00000 | 8482A23 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

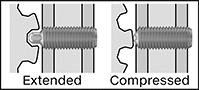

Long-Nose Spring Plungers

|

|

Lock heavy moving parts securely in place. Often used in indexing applications, these have a longer nose than ball-nose spring plungers to withstand greater side forces without disengaging. The nose compresses when a part presses against it, and then pops out into deep notches or grooves for a strong hold.

Spring plungers are available with or without a threadlocker. Those with a threadlocker won't wiggle loose from vibration. Spring plungers without a threadlocker are easier to remove.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

18-8 Stainless Steel Nose—The choice for wet and outdoor environments, 18-8 stainless steel resists rusting. It's strong enough for most jobs, but won't withstand stress and vibration as well as steel.

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Thread Size | Extended Lg. | Wd. | Dia. | Extended | Compressed | Material | Lg. | Drive Style | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.312" | — | 0.374" | 4 | 16 | Black-Oxide Steel | 1.75" | Spring Plunger Driver | 3126A39 | 000000 | 3382A19 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.313" | — | 0.374" | 6.7 | 37.3 | Black-Oxide Steel | 1.75" | Spring Plunger Driver | 3126A61 | 00000 | 3382A19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.313" | 0.375" | — | 6.7 | 37.3 | Black-Oxide Steel | 1.75" | External Hex | 3360A47 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.313" | — | 0.374" | 6.7 | 37.3 | 18-8 Stainless Steel | 1.75" | Spring Plunger Driver | 84975A77 | 00000 | 3382A19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 0.313" | — | 0.374" | 6.7 | 37.3 | Black-Oxide Steel | 1.75" | Spring Plunger Driver | 8490A66 | 00000 | 3382A19 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

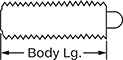

Long-Nose Spring Plungers For Ejecting

|

Punch large parts free from presses or dies with a nose that’s three times longer than others. These spring plungers also have a long spring that doesn’t need to compress as far to retract the nose, so it can handle high speed, repetitive ejecting jobs without wearing down.

Steel Nose—The strongest, most wear-resistant noses, these won't deform from stress and vibration. Steel is best for dry environments, however, since moisture will cause it to rust.

Nose | Nose Force, lbf | Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | Extended Lg. | Wd. | Extended | Compressed | Material | Lg. | Drive Style | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | 1" | 0.375" | 4 | 35 | Black-Oxide Steel | 3.75" | External Hex | 33705A21 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spring Plunger Drivers

|

Install spring plungers from the nose end without depressing the nose.

For Thread Size | For Spring Plunger Nose Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4"-10 | Ball, Long | 3382A19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||