Filter by

System of Measurement

Thread Size

Nose Material

Drive Style

Locking Type

Material

Mount Type

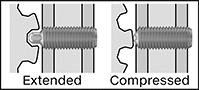

Extended Nose Force

Body Material

Compressed Nose Force

Body Finish

Thread Spacing

Thread Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Finish

Drive Size

Long-Nose Spring Plungers

Spring Plungers | Spring Plunger Drivers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nose | Nose Force, lbf | Body | Drive Style | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

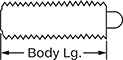

Thread Size | Extended Lg. | Dia. | Extended | Compressed | Material | Lg. | Front | Back | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.036" | 0.046" | 0.5 | 1.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | Slotted | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.046" | 0.5 | 3.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | — | 00000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.38" | Spring Plunger Driver | — | 00000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | Spring Plunger Driver | — | 00000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 316 Stainless Steel | 0.38" | Spring Plunger Driver | Hex | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Brass | 0.38" | Spring Plunger Driver | Hex | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acetal Nose | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.036" | 0.046" | 0.5 | 1.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | Slotted | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 0.5 | 1.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1 | 1.6 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | 18-8 Stainless Steel | 0.53" | — | Hex | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | — | Hex | 0000000 | 0000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.045" | 1.5 | 4.5 | Black-Oxide Steel | 0.53" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | 0.063" | 0.046" | 0.5 | 3.5 | Black-Oxide Steel | 0.38" | Spring Plunger Driver | — | 0000000 | 0000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

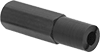

Spring Plunger Drivers

|

For Thread Size | For Spring Plunger Nose Type | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6-32 | Ball, Long | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

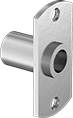

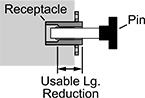

Surface-Mount Quick-Release Pin Receptacles

|  |  |  |  |

Diamond Mounting Flange | Oval Mounting Flange | Rectangular Mounting Flange | Round Mounting Flange |

Mounting Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Pin Dia. | Barrel OD | Overall Lg. | Mounting Hole Thread Size | Wd. | Ht. | Usable Lg. Reduction | Material | Passivation | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Diamond Mounting Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/8" | 5/8" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Passivated | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 11/16" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1/2" | 3/4" | 6-32 | 5/8" | 1 1/4" | 1/2" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 9/16" | 7/8" | 6-32 | 5/8" | 1 1/4" | 9/16" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Mounting Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/8" | 5/8" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 11/16" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1/2" | 3/4" | 6-32 | 5/8" | 1 1/4" | 1/2" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 9/16" | 7/8" | 6-32 | 5/8" | 1 1/4" | 9/16" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Rectangular Mounting Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/8" | 5/8" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 5/8" | 6-32 | 5/8" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1/2" | 13/16" | 6-32 | 5/8" | 1 1/4" | 1/2" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 9/16" | 15/16" | 6-32 | 5/8" | 1 1/4" | 9/16" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Mounting Flange | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16" | 3/8" | 5/8" | 6-32 | 1 1/4" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Passivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 11/16" | 6-32 | 1 1/4" | 1 1/4" | 3/8" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 1/2" | 3/4" | 6-32 | 1 1/4" | 1 1/4" | 1/2" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 9/16" | 7/8" | 6-32 | 1 1/4" | 1 1/4" | 9/16" | 18-8 Stainless Steel | Unpassivated | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||