Filter by

For Use On

Material

System of Measurement

For Finish

Media Treatment

Tumbler Motion

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Tumbling Media for Aluminum, Brass, and Soft Metals

5 lb. | 10 lb. | 15 lb. | 25 lb. | 50 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Density, lb/ft³ | Recommended Media to Parts Ratio | Abrasion Type | Tumbling Condition | Material | Pkg. | Pkg. | Pkg. | Pkg. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Extra-Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

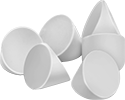

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 000000 | 00000000 | 0000000 | ——— | 0 | 00000000 | 0000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

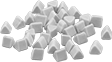

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pyramid | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

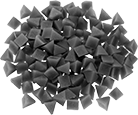

For Ultra Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 40 | 4:1 | None | Dry | Walnut Shell | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

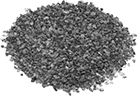

For Polished Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 32 | 4:1 | None | Dry | Corn Cob | ——— | 0 | ——— | 0 | 00000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||