Compare over 20 aluminum alloys to find the right material for you—all with material certificates for traceability.

About Shafts

More

Polished Multipurpose 6061 Aluminum Sheets and Bars

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: 1/4" and 3/8" thick.: T651

All other sizes: T6 - Fabrication: 1/4" and 3/8" thick.: Extruded

All other sizes: Cold Rolled - Specifications Met: ASTM B209

One side of these sheets and bars is polished to either a brushed finish or a mirror-like finish. The polished side is covered with a protective peel-off film. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Brushed sheets and bars are polished to a #4 satin finish with grain lines running in one direction to mask fingerprints.

Mirror-like sheets and bars are polished to a #8 reflective finish and are free of grain lines.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Thick. | Thick. Tolerance | Heat Treatment | Temperature Range, °F | Flatness Tolerance | 2" × 24" | 4" × 24" | 6” × 6” | 6” × 12” | 6" × 24" | 12” × 12” | 12” × 24” | 24” × 24” | |

Brushed | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.032" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.050" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.062" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.080" | -0.004" to 0.004" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.090" | -0.004" to 0.004" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 1/8" | -0.005" to 0.005" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.190" | -0.007" to 0.007" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 1/4" | -0.012" to 0.012" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 3/8" | -0.015" to 0.015" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

Mirror-Like | |||||||||||||

| 0.032" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.050" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.062" | -0.003" to 0.003" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.080" | -0.004" to 0.004" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.090" | -0.004" to 0.004" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 1/8" | -0.005" to 0.005" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 0.190" | -0.007" to 0.007" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 1/4" | -0.012" to 0.012" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

| 3/8" | -0.015" to 0.015" | Hardened | -320° to 300° | 0.125" | 000000 | ||||||||

Polished Multipurpose 6061 Aluminum Rods

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: T6511

- Fabrication: Extruded

- Specifications Met: ASTM B221

Choose between rods that are polished to a brushed finish or a mirror-like finish. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Brushed rods are polished to a #4 satin finish with grain lines running in one direction to mask fingerprints.

Mirror-like rods are polished to a #8 reflective finish and are free of grain lines.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Heat Treatment | Temperature Range, °F | 1 ft. Lg. | 3 ft. Lg. | 6 ft. Lg. | |

Brushed | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | -0.008" to 0.008" | Hardened | -320° to 300° | 0000000 | |||

| 3/8" | -0.008" to 0.008" | Hardened | -320° to 300° | 0000000 | |||

| 1/2" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 5/8" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 3/4" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 1" | -0.013" to 0.013" | Hardened | -320° to 300° | 0000000 | |||

| 1 1/4" | -0.015" to 0.015" | Hardened | -320° to 300° | 0000000 | |||

| 1 1/2" | -0.015" to 0.015" | Hardened | -320° to 300° | 0000000 | |||

| 2" | -0.027" to 0.027" | Hardened | -320° to 300° | 0000000 | |||

Mirror-Like | |||||||

| 1/4" | -0.008" to 0.008" | Hardened | -320° to 300° | 0000000 | |||

| 3/8" | -0.008" to 0.008" | Hardened | -320° to 300° | 0000000 | |||

| 1/2" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 5/8" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 3/4" | -0.010" to 0.010" | Hardened | -320° to 300° | 0000000 | |||

| 1" | -0.013" to 0.013" | Hardened | -320° to 300° | 0000000 | |||

| 1 1/4" | -0.015" to 0.015" | Hardened | -320° to 300° | 0000000 | |||

| 1 1/2" | -0.015" to 0.015" | Hardened | -320° to 300° | 0000000 | |||

| 2" | -0.027" to 0.027" | Hardened | -320° to 300° | 0000000 | |||

Polished Multipurpose 6061 Aluminum 90° Angles

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: T6

- Fabrication: Extruded

- Specifications Met: ASTM B221

The outside of these 90° angles is polished to either a brushed finish or a mirror-like finish, then covered in a protective plastic film. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

Brushed 90° angles are polished to a #4 satin finish with grain lines running in one direction to mask fingerprints.

Mirror-like 90° angles are polished to a #8 reflective finish and are free of grain lines.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Outside | Inside | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ht. | Ht. Tolerance | Wd. | Wd. Tolerance | Ht. | Wd. | Heat Treatment | Temperature Range, °F | 1 ft. Lg. | 4 ft. Lg. | |

Brushed | ||||||||||

1/16" Wall Thick. (-0.017" to 0.017" Tolerance) | ||||||||||

| 1/2" | -0.05" to 0.05" | 1/2" | -0.05" to 0.05" | 0.438" | 0.438" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.1" to 0.1" | 1" | -0.1" to 0.1" | 0.938" | 0.938" | Hardened | -320° to 300° | 0000000 | ||

1/8" Wall Thick. (-0.012" to 0.012" Tolerance) | ||||||||||

| 3/4" | -0.075" to 0.075" | 3/4" | -0.075" to 0.075" | 5/8" | 5/8" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.1" to 0.1" | 1" | -0.1" to 0.1" | 0.938" | 0.938" | Hardened | -320° to 300° | 0000000 | ||

| 1 1/2" | -0.15" to 0.15" | 1 1/2" | -0.15" to 0.15" | 1 3/8" | 1 3/8" | Hardened | -320° to 300° | 0000000 | ||

| 2" | -0.2" to 0.2" | 2" | -0.2" to 0.2" | 1 7/8" | 1 7/8" | Hardened | -320° to 300° | 0000000 | ||

Mirror-Like | ||||||||||

1/16" Wall Thick. (-0.017" to 0.017" Tolerance) | ||||||||||

| 1/2" | -0.05" to 0.05" | 1/2" | -0.05" to 0.05" | 0.438" | 0.438" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.1" to 0.1" | 1" | -0.1" to 0.1" | 0.938" | 0.938" | Hardened | -320° to 300° | 0000000 | ||

1/8" Wall Thick. (-0.012" to 0.012" Tolerance) | ||||||||||

| 3/4" | -0.075" to 0.075" | 3/4" | -0.075" to 0.075" | 5/8" | 5/8" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.1" to 0.1" | 1" | -0.1" to 0.1" | 0.938" | 0.938" | Hardened | -320° to 300° | 0000000 | ||

| 1 1/2" | -0.15" to 0.15" | 1 1/2" | -0.15" to 0.15" | 1 3/8" | 1 3/8" | Hardened | -320° to 300° | 0000000 | ||

| 2" | -0.2" to 0.2" | 2" | -0.2" to 0.2" | 1 7/8" | 1 7/8" | Hardened | -320° to 300° | 0000000 | ||

Polished Multipurpose 6061 Aluminum Round Tubes

- Yield Strength: 35,000 psi

- Hardness: Brinell 95 (Soft)

- Temper: T6

- Fabrication: Extruded

- Specifications Met: ASTM B221

Polished on the outside to a #8 reflective, mirror-like finish, these tubes have no visible grain lines. The polished surface is covered with a protective peel-off film. The most widely used aluminum, 6061 is fabricated into everything from pipe fittings and containers to automotive and aerospace parts. It is strong and corrosion resistant, plus it's easy to machine and weld.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | OD Tolerance | ID | Heat Treatment | Temperature Range, °F | 1 ft. Lg. | 3 ft. Lg. | |

0.065" Wall Thick. (-0.037" to 0.037" Tolerance) | |||||||

|---|---|---|---|---|---|---|---|

| 1/2" | -0.025" to 0.025" | 0.37" | Hardened | -320° to 300° | 0000000 | ||

| 5/8" | -0.025" to 0.025" | 0.495" | Hardened | -320° to 300° | 0000000 | ||

| 3/4" | -0.025" to 0.025" | 0.62" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.025" to 0.025" | 0.87" | Hardened | -320° to 300° | 0000000 | ||

1/8" Wall Thick. (-0.037" to 0.037" Tolerance) | |||||||

| 3/4" | -0.025" to 0.025" | 1/2" | Hardened | -320° to 300° | 0000000 | ||

| 1" | -0.025" to 0.025" | 3/4" | Hardened | -320° to 300° | 0000000 | ||

| 1 1/4" | -0.025" to 0.025" | 1" | Hardened | -320° to 300° | 0000000 | ||

1/4" Wall Thick. (-0.037" to 0.037" Tolerance) | |||||||

| 1" | -0.025" to 0.025" | 1/2" | Hardened | -320° to 300° | 0000000 | ||

| 1 1/4" | -0.025" to 0.025" | 3/4" | Hardened | -320° to 300° | 0000000 | ||

| 1 1/2" | -0.025" to 0.025" | 1" | Hardened | -320° to 300° | 0000000 | ||

| 1 3/4" | -0.025" to 0.025" | 1 1/4" | Hardened | -320° to 300° | 0000000 | ||

| 2" | -0.025" to 0.025" | 1 1/2" | Hardened | -320° to 300° | 0000000 | ||

| 2 1/4" | -0.025" to 0.025" | 1 3/4" | Hardened | -320° to 300° | 0000000 | ||

| 2 1/2" | -0.025" to 0.025" | 2" | Hardened | -320° to 300° | 0000000 | ||

| 3" | -0.025" to 0.025" | 2 1/2" | Hardened | -320° to 300° | 0000000 | ||

| 4" | -0.025" to 0.025" | 3 1/2" | Hardened | -320° to 300° | 0000000 | ||

Polished Easy-to-Weld 5052 Aluminum Sheets and Bars

- Yield Strength: 20,000 psi

- Temper: H32 (1/4 Hard)

- Fabrication: Cold Rolled

- Specifications Met: ASTM B209

One side of these sheets and bars is polished to either a brushed finish or a mirror-like finish. The polished side is covered with a protective, peel-off film. Known for being one of the easiest types of aluminum to weld, 5052 is also recognized for its ability to resist salt water. It's widely used for the bodies of boats, buses, trucks, and trailers, as well as for chemical drums.

Brushed sheets and bars are polished to a #4 satin finish with grain lines running in one direction to mask fingerprints.

Mirror-like sheets and bars are polished to a #8 reflective finish and are free of grain lines.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Thick. | Thick. Tolerance | Temperature Range, °F | 2" × 24" | 4" × 24" | 6” × 6” | 6" × 24" | 12” × 12” | 12” × 24” | 24” × 24” | |

Brushed | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0.032" | -0.003" to 0.003" | -300° to 300° | 00000000 | |||||||

| 0.040" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.050" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.063" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.080" | -0.005" to 0.005" | -300° to 300° | 00000000 | |||||||

| 0.090" | -0.006" to 0.006" | -300° to 300° | 00000000 | |||||||

| 0.100" | -0.006" to 0.006" | -300° to 300° | 00000000 | |||||||

| 1/8" | -0.006" to 0.006" | -300° to 300° | 00000000 | |||||||

| 0.190" | -0.009" to 0.009" | -300° to 300° | 00000000 | |||||||

| 1/4" | -0.014" to 0.014" | -300° to 300° | 00000000 | |||||||

Mirror-Like | ||||||||||

| 0.032" | -0.003" to 0.003" | -300° to 300° | 00000000 | |||||||

| 0.040" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.050" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.063" | -0.004" to 0.004" | -300° to 300° | 00000000 | |||||||

| 0.100" | -0.006" to 0.006" | -300° to 300° | 00000000 | |||||||

| 1/8" | -0.006" to 0.006" | -300° to 300° | 00000000 | |||||||

| 0.190" | -0.009" to 0.009" | -300° to 300° | 00000000 | |||||||

| 1/4" | -0.014" to 0.014" | -300° to 300° | 00000000 | |||||||

Aluminum Balls

Lighter in weight than steel and stronger than plastic, these aluminum balls are widely used in bearings and in valves.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Material | Yield Strength | Temper | Hardness | Heat Treatment | Pkg. Qty. | Pkg. | |

| 1/32" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 000000 |

| 3/64" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 1/16" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 5/64" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 3/32" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 1/8" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 5/32" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 1/4" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 50 | 00000000 | 00000 |

| 1/2" | -0.001" to 0.001" | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 10 | 00000000 | 00000 |

| 7/8" | -0.001" to 0.001" | 2024 Aluminum | 41,000 psi | T351 | Brinell 120 (Medium) | Hardened | 1 | 0000000 | 00000 |

| 1" | -0.001" to 0.001" | 2024 Aluminum | 41,000 psi | T351 | Brinell 120 (Medium) | Hardened | 1 | 0000000 | 00000 |

| 1 1/8" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 00000 |

| 1 1/4" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 00000 |

| 1 3/8" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 00000 |

| 1 1/2" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 00000 |

| 1 3/4" | -0.001" to 0.001" | 6061 Aluminum | 35,000 psi | T6 | Brinell 95 (Soft) | Hardened | 1 | 0000000 | 000000 |

| 2" | -0.001" to 0.001" | 2024 Aluminum | 41,000 psi | T351 | Brinell 120 (Medium) | Hardened | 1 | 0000000 | 000000 |

| 1mm | -0.025mm to 0.025mm | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 2mm | -0.025mm to 0.025mm | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

| 3mm | -0.025mm to 0.025mm | 2017 Aluminum | 32,000 psi | T4 | Brinell 110 (Soft) | Hardened | 100 | 00000000 | 00000 |

Linear Motion Shafts

Smooth, hard, and wear resistant, these shafts work with linear bearings to reduce friction in manual and automated systems, such as those found in packing, machine tool, and material handling operations. All are turned, ground, and polished to tight diameter and straightness tolerances.

Aluminum shafts are a lightweight, corrosion-resistant option for use with linear sleeve bearings. Because they have a soft core, they shouldn’t be used with linear ball bearings, which may dent the shaft. Both anodized aluminum and ceramic-coated aluminum have an ultra-hard coating for wear resistance. Ceramic-coated aluminum shafts are good for harsh environments, preventing welding spatter, molten glass, and paint from sticking.

Surface smoothness—The lower the microinch value, the smoother the finish and the less friction and wear it will cause on the bearing.

| Lg. | Lg. Tolerance | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Each | |

1/4" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

|---|---|---|---|---|---|---|---|---|

| 12" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 18" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 36" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 48" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

3/8" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 6" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

1/2" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 48" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

3/4" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 18" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

7/8" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 6" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

1" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 6" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 12" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

1 1/4" Dia. (Tolerance: -0.001" to -0.0005") | ||||||||

| 18" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.0625" to 0.0625" | 0.004" per ft. | 16 | Straight | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| Lg. | Lg. Tolerance | Straightness Tolerance | Surface Smoothness, microinch | Edge Type | Hardness Rating | Hardness | Each | |

1/4" Dia. (Tolerance: -0.0012" to -0.0004") | ||||||||

|---|---|---|---|---|---|---|---|---|

| 6" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 9" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 36" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 48" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

3/8" Dia. (Tolerance: -0.0012" to -0.0004") | ||||||||

| 6" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 36" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 48" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

1/2" Dia. (Tolerance: -0.0012" to -0.0004") | ||||||||

| 6" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 36" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 48" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

3/4" Dia. (Tolerance: -0.0012" to -0.0004") | ||||||||

| 6" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 36" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 48" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

1" Dia. (Tolerance: -0.0012" to -0.0004") | ||||||||

| 6" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 36" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 48" | -0.03" to 0.03" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

1 1/2" Dia. (Tolerance: -0.0013" to -0.0005") | ||||||||

| 6" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 15" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 18" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 24" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

2" Dia. (Tolerance: -0.0015" to -0.0005") | ||||||||

| 6" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 15" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.06" to 0.06" | 0.001" per ft. | 12 | Chamfered | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

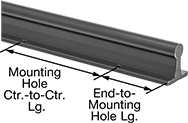

Support-Rail Shafts

These shafts include a support rail for a stable setup that eliminates bending and prevents linear bearings from rotating. Shafts have a smooth surface to reduce friction and wear on linear bearings—the lower the microinch value a shaft has, the smoother its finish and the less friction it will create. They are case-hardened to increase hardness and wear resistance on the surface of the shaft while allowing the center to remain soft for absorbing stresses caused by shifting loads. The edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, and polished to tight diameter and straightness tolerances.

One-piece shafts reduce vibration and assembly time.

Ceramic-coated aluminum shafts are good for use in harsh environments; a 0.002" thick ceramic coating prevents weld spatter, molten glass, and paint from sticking to the shaft. They are lighter in weight than steel and stainless steel shafts. Because they have a soft core, they are not for use with linear ball bearings, which may dent the shaft.

Mounting Hole | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. Tolerance | Ctr. Ht. | O'all Wd. | End-to-Mount. Hole Lg. | Ctr.-to-Ctr. Lg. | Ctr.-to-Ctr. Wd. | Dia. | Mounting Fasteners Included | Surface Smoothness, microinch | Hardness Rating | Hardness | Each | |

Inch—Ceramic-Coated 6063 Aluminum (T6 Temper) | |||||||||||||

1/2" Dia. (Tolerance: -0.0012" to -0.0004") | |||||||||||||

| 6" | -0.03" to 0.03" | 1 1/8" | 1 1/2" | 1" | 4" | 1" | 5/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 9" | -0.03" to 0.03" | 1 1/8" | 1 1/2" | 2 1/2" | 4" | 1" | 5/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 1 1/8" | 1 1/2" | 2" | 4" | 1" | 5/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 18" | -0.03" to 0.03" | 1 1/8" | 1 1/2" | 1" | 4" | 1" | 5/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.03" to 0.03" | 1 1/8" | 1 1/2" | 2" | 4" | 1" | 5/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

3/4" Dia. (Tolerance: -0.0012" to -0.0004") | |||||||||||||

| 6" | -0.03" to 0.03" | 1 1/2" | 1 3/4" | 3" | 6" | 1 1/4" | 7/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 1 1/2" | 1 3/4" | 1 1/2" | 6" | 1 1/4" | 7/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 12" | -0.03" to 0.03" | 1 1/2" | 1 3/4" | 3" | 6" | 1 1/4" | 7/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 18" | -0.03" to 0.03" | 1 1/2" | 1 3/4" | 3" | 6" | 1 1/4" | 7/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.03" to 0.03" | 1 1/2" | 1 3/4" | 3" | 6" | 1 1/4" | 7/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

1" Dia. (Tolerance: -0.0012" to -0.0004") | |||||||||||||

| 6" | -0.03" to 0.03" | 1 3/4" | 2 1/8" | 3" | 6" | 1 1/2" | 9/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 00000 |

| 9" | -0.03" to 0.03" | 1 3/4" | 2 1/8" | 1 1/2" | 6" | 1 1/2" | 9/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 12" | -0.03" to 0.03" | 1 3/4" | 2 1/8" | 3" | 6" | 1 1/2" | 9/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 18" | -0.03" to 0.03" | 1 3/4" | 2 1/8" | 3" | 6" | 1 1/2" | 9/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

| 24" | -0.03" to 0.03" | 1 3/4" | 2 1/8" | 3" | 6" | 1 1/2" | 9/32" | No | 12 | Ultra Hard | Rockwell C70 | 0000000 | 000000 |

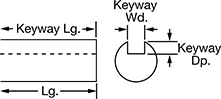

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

2024 aluminum shafts are lightweight, corrosion resistant, and nonmagnetic. They have a T4 temper, which means they have been heat treated for increased strength.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—2024 Aluminum | ||||||||||

5/16" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 000000 |

| 12" | 12" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

3/8" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 12" | 12" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.094" | 3/64" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

1/2" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.125" | 1/16" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 12" | 12" | 0.125" | 1/16" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.125" | 1/16" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

5/8" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 12" | 12" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

3/4" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 12" | 12" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

1" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 6" | 6" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 12" | 12" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |

| 24" | 24" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Soft | Brinell 120 | 0000000 | 00000 |