About Finishing

More

Smoothing and Polishing Stones

Maintain tools, molds, and dies. These stones can be used by hand or in power tools with a compatible holder. Choose the shape that best matches the contour of your work surface.

Aluminum–oxide stones abrade slowly to create a consistent surface. Also known as India stones.

| Grit (For Finish) | Lg. | Wd. | Color | Lubrication | Each | |

Aluminum Oxide—For Use On Steel | ||||||

|---|---|---|---|---|---|---|

| 100 (Smooth) | 4" | 1/4" | Gray | Oil Filled | 0000000 | 000000 |

| 100 (Smooth) | 4" | 3/8" | Gray | Oil Filled | 0000000 | 00000 |

| 100 (Smooth) | 4" | 1/2" | Gray | Oil Filled | 0000000 | 00000 |

| 100 (Smooth) | 6" | 1/2" | Gray | Oil Filled | 0000000 | 00000 |

| 100 (Smooth) | 6" | 3/4" | Gray | Oil Filled | 0000000 | 00000 |

| 100 (Smooth) | 6" | 1" | Gray | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 4" | 1/4" | Brown | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 4" | 3/8" | Brown | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 4" | 1/2" | Brown | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 6" | 1/2" | Brown | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 6" | 3/4" | Brown | Oil Filled | 0000000 | 00000 |

| 240 (Extra Smooth) | 6" | 1" | Brown | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 4" | 1/4" | Orange | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 4" | 3/8" | Orange | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 4" | 1/2" | Orange | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 6" | 1/2" | Orange | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 6" | 3/4" | Orange | Oil Filled | 0000000 | 00000 |

| 320 (Extra Smooth) | 6" | 1" | Orange | Oil Filled | 0000000 | 00000 |

Fast-Cutting Smoothing Stones

Also known as Crystolon stones, these abrade quickly to create a smooth or extra-smooth finish on molds and dies. These stones can be used by hand or in power tools with a compatible holder. Choose the shape that best matches the contour of your work surface. We recommend using a water-soluble or oil-based lubricant with stones that are not oil filled.

| Grit (For Finish) | Lg. | Wd. | Color | Lubrication | Each | |

Silicon Carbide—For Use On Steel | ||||||

|---|---|---|---|---|---|---|

| 150 (Smooth) | 4" | 1/4" | Gray | Recommended | 0000000 | 000000 |

| 150 (Smooth) | 4" | 3/8" | Gray | Recommended | 0000000 | 00000 |

| 150 (Smooth) | 4" | 1/2" | Gray | Recommended | 0000000 | 00000 |

| 280 (Extra Smooth) | 4" | 1/4" | Black | Recommended | 0000000 | 00000 |

| 280 (Extra Smooth) | 4" | 3/8" | Black | Recommended | 0000000 | 00000 |

| 280 (Extra Smooth) | 4" | 1/2" | Black | Recommended | 0000000 | 00000 |

Uniform-Finish Polishing Stones

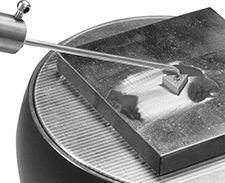

Prevent uneven polishing marks. Unlike other polishing stones, these stones never leave your work surface for a uniform finish. You move them around with a lapping rod (sold separately), which you can lift off to pause your work—instead of removing the stone. Choose the stone shape that best matches the contour of your work surface.

Lubricate your work surface with either a water-soluble or oil-based lubricant. To make sure the lapping rod doesn’t slip off of the polishing stone as you work, create a small indentation in the stone with a diamond grinding bit. For best results, install the lapping rod in a reciprocating polisher.

Aluminum oxide stones, also known as India stones, scrape away material slowly to give you more control over how much material you remove. They are good for the final stage of polishing.

Silicon carbide stones, also known as Crystolon stones, are extremely sharp. These stones remove material more quickly than aluminum oxide stones. They are best for the early polishing stage when you want to clear away more material from your work surface. However, they give you less control over material removal than aluminum oxide stones, so stopping at an exact point is more difficult to do.

Stones | Required Lapping Rods | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grit (For Finish) | Lg. | Wd. | Color | Lubrication | Pkg. Qty. | Pkg. | Each | ||

Aluminum Oxide—For Use On Aluminum, Steel | |||||||||

| 400 (Extra Smooth) | 1/2" | 1/2" | Beige | Required | 10 | 00000000 | 00000 | 00000000 | 000000 |

| 600 (Polished) | 1/2" | 1/2" | Beige | Required | 10 | 00000000 | 0000 | 00000000 | 00000 |

| 1000 (Polished) | 1/2" | 1/2" | Beige | Required | 10 | 00000000 | 0000 | 00000000 | 00000 |

Silicon Carbide—For Use On Aluminum, Steel | |||||||||

| 400 (Extra Smooth) | 1/2" | 1/2" | Green | Required | 10 | 00000000 | 0000 | 00000000 | 00000 |

| 600 (Polished) | 1/2" | 1/2" | Green | Required | 10 | 00000000 | 0000 | 00000000 | 00000 |

| 800 (Polished) | 1/2" | 1/2" | Green | Required | 10 | 00000000 | 0000 | 00000000 | 00000 |