Filter by

Material

Screw Size

OD

Thickness

ID

Washer Type

Maximum Temperature

DFARS Specialty Metals

RoHS

Minimum Temperature

Specifications Met

Export Control Classification Number (ECCN)

Sold As

Thread Type

Certification

Mount Type

Hardness Rating

Environment

Tensile Strength

Plastic Washers

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID | OD | Thk. | Min. | Max. | Specs. Met | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clear Impact-Resistant Polycarbonate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 0 | 0.078" | 0.188" | 0.016" to 0.025" | Not Rated | 212 | ASME B18.21.1 | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 2 | 0.090" | 0.250" | 0.027" to 0.037" | Not Rated | 212 | — | Clear | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.115" | 0.250" | 0.027" to 0.037" | Not Rated | 212 | — | Clear | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 4 | 0.125" | 0.312" | 0.029" to 0.033" | -200 | 270 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 5 | 0.140" | 0.312" | 0.027" to 0.037" | Not Rated | 212 | — | Clear | 100 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 5 | 0.141" | 0.350" | 0.036" to 0.045" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.156" | 0.312" | 0.029" to 0.033" | -200 | 270 | ASME B18.22.1 | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 6 | 0.156" | 0.375" | 0.036" to 0.065" | -40 | 300 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.170" | 0.375" | 0.025" to 0.035" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 8 | 0.188" | 0.438" | 0.036" to 0.065" | -40 | 300 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.194" | 0.375" | 0.025" to 0.035" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 10 | 0.219" | 0.500" | 0.036" to 0.044" | -200 | 270 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| No. 12 | 0.250" | 0.562" | 0.051" to 0.080" | Not Rated | 212 | ASME B18.21.1 | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.257" | 0.500" | 0.055" to 0.069" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.375" | 0.058" to 0.066" | -200 | 270 | ASME B18.22.1 | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 0.281" | 0.625" | 0.058" to 0.066" | -200 | 270 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.317" | 0.500" | 0.055" to 0.069" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 0.344" | 0.688" | 0.058" to 0.066" | -200 | 270 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.380" | 0.625" | 0.055" to 0.069" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.734" | 0.058" to 0.066" | -200 | 270 | ASME B18.22.1 | Clear | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 0.406" | 0.812" | 0.051" to 0.080" | -40 | 300 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 0.469" | 1.250" | 0.051" to 0.080" | Not Rated | 212 | — | Clear | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 0.505" | 0.750" | 0.055" to 0.069" | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 0.594" | 1.469" | 0.074" to 0.121" | Not Rated | 212 | — | Clear | 5 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 0.656" | 1.750" | 0.074" to 0.121" | Not Rated | 212 | — | Clear | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 0.812" | 2.000" | 0.108" to 0.160" | Not Rated | 212 | — | Clear | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 0.938" | 2.250" | 0.108" to 0.160" | Not Rated | 212 | — | Clear | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1.062" | 2.500" | 0.108" to 0.160" | Not Rated | 212 | — | Clear | 1 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.1 mm | 4.0 mm | 0.4 mm to 0.6 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 mm | 5.0 mm | 0.2 mm to 0.4 mm | Not Rated | 220 | — | Clear | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 2.7 mm | 5.0 mm | 0.4 mm to 0.6 mm | Not Rated | 200 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.5 | 2.9 mm | 6.0 mm | 0.5 mm to 0.6 mm | Not Rated | 220 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2.6 | 2.7 mm | 6.0 mm | 0.4 mm to 0.6 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 mm | 6.0 mm | 0.5 mm to 0.6 mm | Not Rated | 220 | — | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 mm | 7.0 mm | 0.4 mm to 0.6 mm | Not Rated | 220 | DIN 125 | Clear | 25 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.2 mm | 9.0 mm | 0.5 mm to 1.1 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.3 mm | 8.0 mm | 0.7 mm to 1.0 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3 | 3.3 mm | 10.0 mm | 0.7 mm to 1.0 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M3.5 | 3.7 mm | 8.0 mm | 0.5 mm to 1.1 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.3 mm | 9.0 mm | 0.5 mm to 1.1 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M4 | 4.5 mm | 10.0 mm | 0.7 mm to 0.9 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M5 | 5.5 mm | 12.0 mm | 0.7 mm to 0.9 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.4 mm | 12.0 mm | 1.2 mm to 1.8 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.5 mm | 13.0 mm | 0.9 mm to 1.1 mm | Not Rated | 212 | — | Clear | 50 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 6.8 mm | 17.0 mm | 2.7 mm to 3.4 mm | Not Rated | 220 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.5 mm | 15.8 mm | 1.3 mm to 1.9 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M8 | 8.5 mm | 18.0 mm | 1.4 mm to 1.8 mm | Not Rated | 212 | — | Clear | 25 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M10 | 10.5 mm | 22.0 mm | 1.4 mm to 1.8 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M12 | 13.0 mm | 24.0 mm | 2.2 mm to 2.8 mm | Not Rated | 212 | — | Clear | 10 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Unthreaded Spacers

|

Lg. | For Screw Size | ID | Temp. Range, ° F | Specs. Met | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Clear Impact-Resistant Polycarbonate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | No. 10 | 0.192" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1/4" | 0.252" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4" OD | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/4" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/2" | 3/8" | 0.380" | -40 to 250 | ASTM D3935 | Clear | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

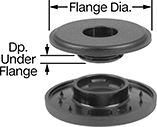

Snap-In Fabric Grommets

Grommet Trade Size | For Max. Material Thk. | ID | Flange Dia. | Dp. Under Flange | Color | Temp., ° F | For Use Outdoors | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Polycarbonate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 | 0.203" | 3/8" | 1 1/8" | 13/32" | Black | -150 to 250 | Yes | 10 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hands-Free Static-Eliminating Blowguns

Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nozzle Lg. | Air Consumption @ Pressure | Volume (Sound) | Static Neutralizing Distance | Arm Lg. | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Nozzle Tip Material | Grip Style | Voltage, V AC | Cord Lg., ft. | Specs. Met | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight with Straight Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Trigger Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 7.4 ft³/min @ 100 psi | Not Rated | 1" to 36" | 18" | 100 | 1/4 | NPT | Female | Nickel | Plain | 120 | 6 | OSHA Compliant 29 CFR 1910.242 | C-UL Listed, UL Listed | 0000000 | 000000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Static-Eliminating Blowguns

Air Inlet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Nozzle Lg. | Air Consumption @ Pressure | Volume (Sound), dBA | Static Neutralizing Distance | Removes Particle Size Down To, μm | Max. Inlet Pressure, psi | Pipe Size | Thread Type | Gender | Nozzle Tip Material | Grip Style | Voltage, V AC | Clean Room Std. | Cord Lg., ft. | Specs. Met | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Straight with Straight Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lever Control | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 7/8" | 7.4 ft³/min @ 100 psi | 97 | 4" to 10" | 0.01 | 100 | 1/4 | NPT | Female | Nickel | Plain | 120 | Fed. Std. Class 1,000; ISO Class 6 | 6 | OSHA Compliant 29 CFR 1910.242 | Power and Ionization-Indicating LED | 00000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

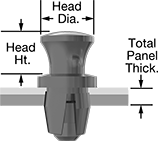

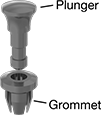

Push/Pull Captive Panel Screws

For Panel Thk. | For Panel Hole Dia. | Head | Material | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Max. Outer | Total | Inner | Outer | Lg. | Dia. | Ht. | Plunger | Grommet | Temp., ° F | Flammability Rating | Color | Pkg. Qty. | Pkg. | |||

| 0.042" | 0.056" to 0.153" | 0.189" | 0.18" | 11/32" | 0.25" | 0.266" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 000000 | ||

| 0.042" | 0.059" to 0.148" | 0.25" | 0.238" | 3/8" | 0.313" | 0.28" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.042" | 0.059" to 0.148" | 0.316" | 0.294" | 3/8" | 0.375" | 0.3" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.065" | 0.079" to 0.176" | 0.189" | 0.18" | 23/64" | 0.25" | 0.266" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.065" | 0.084" to 0.173" | 0.25" | 0.238" | 25/64" | 0.313" | 0.28" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.065" | 0.084" to 0.173" | 0.316" | 0.294" | 25/64" | 0.375" | 0.3" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.098" | 0.112" to 0.209" | 0.189" | 0.18" | 25/64" | 0.25" | 0.266" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.098" | 0.118" to 0.207" | 0.25" | 0.238" | 7/16" | 0.313" | 0.28" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.098" | 0.118" to 0.207" | 0.316" | 0.294" | 7/16" | 0.375" | 0.3" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.138" | 0.152" to 0.249" | 0.189" | 0.18" | 7/16" | 0.25" | 0.266" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.162" | 0.182" to 0.271" | 0.25" | 0.238" | 1/2" | 0.313" | 0.28" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||

| 0.162" | 0.182" to 0.271" | 0.316" | 0.294" | 1/2" | 0.375" | 0.3" | Nylon | Polycarbonate | -20 to 185 | UL 94 V-2 | Black | 10 | 000000000 | 00000 | ||