How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

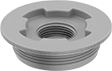

Drum Plugs

For installation and removal of these plugs, use drum-plug wrenches.

Style D have a M64 thread size, which is also known as Buttress threads.

Drum-plug caps (sold separately) fit over drum plugs to provide dust protection as well as evidence of tampering. They have a breakaway seal and are for one-time use.

Drum Plugs | Crimp-On Drum Plug Caps | Crimping Tools for Drum Plug Caps | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Drum Plug Type | Color | Seal Material | Pipe/Thread Size | Gender | Max. Temp., °F | Opening Pressure Range | Features | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Each | |||

| A | Standard | Gray | __ | 3/4 NPSM | Male | 125° | __ | __ | 5 | 0000000 | 000000 | 10 | 0000000 | 000000 | 0000000 | 0000000 |

| A | Pressure Relief, Vacuum Relief | Gray | __ | 3/4 NPSM | Male | 125° | 1 psi-4 psi | Vent | 5 | 0000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| B | Pressure Relief, Vacuum Relief | White | EPDM Rubber | 2 NPSM | Male | 125° | 1 psi-4 psi | Vent | 5 | 0000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| C | Standard | Gray | __ | 2 NPSM | Male | 125° | __ | 3/4 NPSM Faucet Knockout | 5 | 0000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

| D | Standard | White | __ | M64 Metric | Male | 125° | __ | 3/4 NPSM Faucet Knockout | 5 | 0000000 | 00000 | 10 | 0000000 | 00000 | 0000000 | 000000 |

UV-Resistant Polypropylene Pipe Fittings for Chemicals

Made of polypropylene, these fittings won’t deteriorate when exposed to the damaging effects of ultraviolet light and are suitable to use outdoors. They have the chemical resistance to withstand a wide variety of acids, solvents, and other harsh substances. Apply a non-hardening, plastic-compatible sealant to the male threads to prevent leaks. Tape or sealants with PTFE are not recommended for plastic-to-plastic threaded connections. When making a threaded connection be careful not to overtighten the threads. To prevent cracks and leaks, finger tighten the fitting, then wrench-tighten one to two turns.

Schedule 40 fittings have thinner walls than Schedule 80 fittings and are typically used in commercial and residential applications.

Schedule 80 fittings have thicker, stronger walls than Schedule 40 fittings for heavy duty, industrial chemical processing applications.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

- Temperature Range: 0° to 150° F

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size | Schedule | Material | Color | Max. Pressure | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 3/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 2 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| 3 | 80 | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

- For Use With:

Pipe Sizes 1/8 to 1/2: Air, Calcium Chloride, Sodium Chloride, Water

Pipe Sizes 3/4 to 3: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water - Temperature Range: 32° to 140° F

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

| Pipe Size | Schedule | Drive Size | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/8 | 40 | 5/8" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 00000 |

| 1/4 | 40 | 5/8" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/8 | 40 | 3/4" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 1/2 | 40 | 1" | Polypropylene Plastic | Black | 150 psi @ 72° F | 00000000 | 0000 |

| 3/4 | 80 | 1 5/16" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 | 80 | 1 9/16" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 1/4 | 80 | 2" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 1 1/2 | 80 | 2 1/16" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 2 | 80 | 2 1/2" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 0000 |

| 3 | 80 | 4 5/16" | Polypropylene Plastic | Black | 300 psi @ 72° F | 000000000 | 00000 |

| Non-Hardening Thread Sealant (8-oz. Brush-Top Can) | 000000 | Each | 000000 |

Easy-Access UV-Resistant Polypropylene Pipe Fittings for Chemicals

- For Use With:

Fittings: Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sodium Hydroxide, Sulfuric Acid (30%), Water

Gaskets: See Gaskets - Temperature Range:

Fittings: 0° to 150° F

Gaskets: See Gaskets

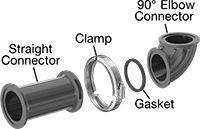

Also known as manifold flange fittings, these have a clamp-together design that lets you access your line for routine maintenance. Connect the flanged end to another quick-clamp fitting with a clamp and a gasket (all sold separately). Fittings are polypropylene, which resists a wide variety of acids, solvents, and other harsh chemicals. The fittings won’t deteriorate when exposed to the damaging effects of ultraviolet light, so they’re suitable for outdoor use.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

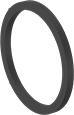

| For Pipe Size | For Flange OD | OD | ID | Thick. | Color | Temp. Range, ° F | For Use With | Each | |

EPDM Rubber | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2 | 3 19/64" | 2 5/8" | 2.188" | 1/4" | Black | 0° to 300° | Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Water | 0000000 | 00000 |

| 3 | 4 13/32" | 3.719" | 3.188" | 1/4" | Black | 0° to 300° | Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Water | 0000000 | 0000 |

Viton® Fluoroelastomer Rubber | |||||||||

| 2 | 3 19/64" | 2 5/8" | 2" | 1/4" | Black | 0° to 400° | Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (30%), Water | 0000000 | 00000 |

| 3 | 4 13/32" | 3.719" | 3" | 1/4" | Black | 0° to 400° | Acetic Acid (5%), Calcium Chloride, Hydrochloric Acid (10%), Phosphoric Acid (85%), Salt Water, Sulfuric Acid (30%), Water | 0000000 | 00000 |

High-Purity Polypropylene Pipe Fittings for Corrosive Chemicals

The inside of these fittings won’t leach contaminants into your line or accumulate particles—they’re polished to an ultra-smooth 12 Ra finish, which also makes them easy to clean. Made of polypropylene, they resist organic solvents, acids, and alkalis better than CPVC fittings. These fittings meet NSF/ANSI 61 for use with drinking water, and they’re FDA compliant for direct contact with food. They also meet ASTM requirements for material and performance, and ISO requirements for dimensions.

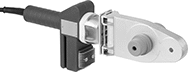

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Pipe Nipples and Pipe: Use SDR 11 Polypropylene Plastic

- Flanges: Use Polypropylene Plastic

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

| 1/2 | 19/32" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 5/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1 | 45/64" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 1 1/2 | 15/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

| 2 | 1 1/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 00000 |

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Seal Material: See table

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

EPDM Rubber Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber Seal | ||||||||

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| Each | ||

| 00000000 | 0000000 |

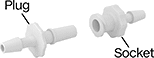

High-Flow Quick-Disconnect Tube Couplings for Air and Water

- Temperature Range: Acetal Plastic: 32° to 180° F

Polypropylene Plastic: 32° to 160° F - Tubing: Use with soft or firm (Durometer 55A-95A) nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PVC plastic or TPE plastic

- Specifications Met: Acetal Plastic: FDA Compliant 21 CFR 177.2470

Polypropylene Plastic: FDA Compliant 21 CFR 177.1520

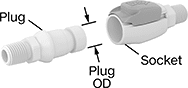

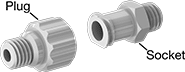

A spring-free flow path allows more air or water to pass through these tube couplings at lower line pressures than other quick-disconnect couplings. This reduces turbulence, foaming, bubbles, and blockage. They have a shut-off valve that stops the flow when the coupling is disconnected, so air or water won’t leak from your line. Unlike couplings with a button release, these have a safety slide to reduce accidental separation from bumps or drops. They’re often used in laboratories, pharmaceutical facilities, and other sterile environments. All are FDA compliant for direct contact with food.

When you insert the plug into the socket, it’ll connect with a click. To disconnect, slide the latch on the socket and remove the plug.

Polypropylene plugs and sockets are flexible yet tough, so they keep their shape and strength after repeated use. They are more water resistant than acetal plugs and sockets and can be completely submerged.

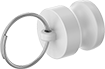

End plugs fit in the end of a socket to keep out dirt and debris.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

| Plug OD | Coupling Size | Color | Clarity | Max. Pressure | Each | |

Polypropylene Plastic | ||||||

|---|---|---|---|---|---|---|

| 9/16" | 1/8 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 00000 |

| 9/16" | 3/16 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

| 11/16" | 1/4 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

| 11/16" | 3/8 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

| 1" | 1/2 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

| 1" | 5/8 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

| 1" | 3/4 | Orange | Opaque | 90 psi @ 72° F | 0000000 | 0000 |

Plastic Luer Lock Tube Couplings for Air and Water

- For Use With: Nylon Plastic: Air, Water

Polycarbonate Plastic: Air

Polypropylene Plastic: Water - Temperature Range: See table

- Tubing: Use with soft (Durometer 40A-65A) PVC plastic or silicone rubber

Made of plastic, these couplings are lighter in weight than metal luer lock couplings. They're a popular choice in labs because of their versatility—they fit any other luer lock plug, socket, syringe, or needle. Quick to attach and detach, they’re often used in lines that are frequently disconnected. They have a compact body for easy installation in tight spaces. Use them in low-pressure applications. These couplings are open-flow style, so there is no shut-off valve to stop the flow when they’re separated.

Polypropylene couplings won’t absorb water and lose strength, even in high-humidity environments. They also stand up to chemicals, including solvents.

Plugs with a locking ring are more secure than those without a locking ring. Give the ring a half turn to lock these couplings in place. You can’t remove the locking ring.

Plugs without a locking ring are quicker to install and remove than those with a locking ring. Also known as luer slip couplings, all they need is a light push to secure. Add a snap-on ring (sold separately) to lock your coupling in place and color code your line.

Note: For a complete coupling, order a plug and a socket.

Tie plugs with a tether ring to equipment so they’re always where you need them.

Plugs with a vented tip release fluid and gases trapped below the cap, making them a good choice for vacuum applications.

| Color | Clarity | Max. Pressure | Temp. Range, °F | Features | Locking Ring Included | Pkg. Qty. | Pkg. | |

Polypropylene Plastic | ||||||||

|---|---|---|---|---|---|---|---|---|

Open Tip | ||||||||

| White | Semi-Clear | 40 psi @ 72° F | 35° to 150° F | __ | With Locking Ring | 10 | 000000000 | 00000 |

| White | Semi-Clear | Not Rated | Not Rated | __ | Without Locking Ring | 10 | 000000000 | 0000 |

| White | Semi-Clear | Not Rated | Not Rated | Tether Ring | Without Locking Ring | 10 | 000000000 | 0000 |

| White | Semi-Clear | Not Rated | Not Rated | Vented Tip | With Locking Ring | 10 | 000000000 | 0000 |

Closed Tip | ||||||||

| White | Semi-Clear | Not Rated | Not Rated | __ | With Locking Ring | 10 | 000000000 | 0000 |

Combo cap/plugs close off a plug on one end and a socket with the other. They save space by doing the job of both a cap and an end plug.

| Color | Clarity | Max. Pressure | Temp. Range, °F | Locking Ring Included | Pkg. Qty. | Pkg. | |

Polypropylene Plastic | |||||||

|---|---|---|---|---|---|---|---|

Open Tip | |||||||

| White | Semi-Clear | Not Rated | Not Rated | With Locking Ring | 10 | 000000000 | 00000 |

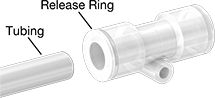

Push-to-Connect Fittings for Plastic Tubing—High-Purity

- For Use With: Air, Nitrogen, Water

- Temperature Range: 32° to 100° F

- Tubing: Use with polypropylene plastic

Also known as instant fittings, these connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect, push on the release ring and pull the tubing out of the fitting. Fittings are produced in a clean room and are double bagged to prevent dirt and moisture from contaminating the inside. They are polypropylene, which has excellent impact and abrasion resistance.

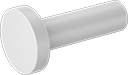

Plugs insert into the push-to-connect end of another fitting.

| Tube Stem OD | Material | Color | Max. Pressure | Each | |

| 1/4" | Polypropylene Plastic | White | 100 psi @ 72° F | 00000000 | 00000 |

| 3/8" | Polypropylene Plastic | White | 100 psi @ 72° F | 00000000 | 0000 |

| 1/2" | Polypropylene Plastic | White | 100 psi @ 72° F | 00000000 | 0000 |

| 4mm | Polypropylene Plastic | White | 140 psi @ 72° F | 00000000 | 0000 |

| 6mm | Polypropylene Plastic | White | 140 psi @ 72° F | 00000000 | 0000 |

| 8mm | Polypropylene Plastic | White | 140 psi @ 72° F | 00000000 | 0000 |

| 12mm | Polypropylene Plastic | White | 140 psi @ 72° F | 00000000 | 0000 |

Luer Lock Tube Couplings for Plastic and Rubber Tubing—High-Purity

- For Use With: Air, Water

- Temperature Range: Nylon Plastic: -50° to 275° F

Polyolefin Plastic: Up to 355° F

Polypropylene Plastic: -5° to 150° F - Tubing: Use with soft or firm (Durometer 50A-95A) polyolefin plastic, PVC plastic, silicone rubber, TPE plastic, or TPU plastic

To prevent contamination, these couplings are cleaned, double bagged, and packaged in a clean room. This makes them a great choice for applications where cleanliness is critical, such as semiconductor manufacturing. Known for their versatility, they fit any luer lock plug, socket, syringe, or needle. They’re quick to attach and detach, so they’re often used in lines that are frequently disconnected. Thanks to their compact body, they fit in tight spaces. Use them in low-pressure applications.

Note: For a complete coupling, order a plug and a socket. Polypropylene couplings resist moisture and chemicals, including solvents. They also stand up to impact and abrasion.

Plugs with a locking ring are more secure than those without a locking ring. Give the ring a half turn to lock them in place. You can’t remove the locking ring.

| Color | Clarity | Max. Pressure | Environmental Rating | Locking Ring Included | Pkg. Qty. | Pkg. | |

Polypropylene Plastic | |||||||

|---|---|---|---|---|---|---|---|

Open Tip | |||||||

| White | Semi-Clear | Not Rated | ISO Class 7 | With Locking Ring | 5 | 00000000 | 00000 |

Push-to-Connect Fittings for Food and Beverage

- Temperature Range: 35° to 140° F

- Tubing: See table

- Specifications Met: See table

Also known as instant fittings, these connect to tubing with a push, and an internal gripping ring and O-ring hold the tubing tight. To disconnect fittings with a release ring, push on the release ring and pull the tubing out of the fitting.

Polypropylene fittings have excellent impact and abrasion resistance. They meet NSF/ANSI standards for safe use with food. Some are also FDA compliant for indirect contact with food.

Black fittings have excellent UV resistance and are suitable for outdoor environments.

Plugs insert into the push-to-connect end of another fitting.

| Tube Stem OD | Material | Max. Pressure | Specifications Met | Each | |

White | |||||

|---|---|---|---|---|---|

| 1/4" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 51, NSF/ANSI 61 | 0000000 | 00000 |

| 5/16" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 51, NSF/ANSI 61 | 00000000 | 0000 |

| 3/8" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 51, NSF/ANSI 61 | 0000000 | 0000 |

| 1/2" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 51, NSF/ANSI 61 | 0000000 | 0000 |

Black | |||||

| 1/4" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 0000000 | 000 |

| 5/16" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 00000000 | 0000 |

| 3/8" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 0000000 | 0000 |

| 1/2" | Polypropylene Plastic | 150 psi @ 72° F | NSF/ANSI 58, NSF/ANSI 372, FDA Compliant 21 CFR 176.170 | 0000000 | 0000 |

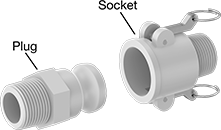

Cam-and-Groove Hose Couplings for Food and Beverage

Made of FDA listed materials, these couplings are suitable for food and beverage applications and won’t impart tastes or odors to the product. They also meet NSF/ANSI 61 safety standards for use with drinking water systems. A complete coupling consists of a plug and a socket (both sold separately) that allow you to quickly connect and disconnect medium-to large-diameter hose lines. To connect, insert the plug into the socket and press the levers down. The levers fit snugly into the groove on the plug’s body and force the plug against the gasket to form a tight seal. To disconnect, lift both levers and pull out the plug. Plugs and sockets are polypropylene, which is lightweight with good abrasion and corrosion resistance.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size.

Warning: Relieve all pressure before disconnecting the couplings. Do not use cam-and-groove couplings with compressed air or gas.

- Maximum Pressure: See table

- Temperature Range: 10° to 180° F

- Specifications Met: FDA Compliant 21 CFR 176.170

FDA Compliant 21 CFR 178.3297

NSF/ANSI 61