How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Thick-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 80 pipe. With thicker, stronger walls than standard-wall fittings, they can handle heavy duty supply applications, such as water processing, wastewater treatment, and irrigation. Fittings are plastic for good corrosion resistance. They meet ASTM specifications and testing requirements for material quality.

To prevent leaks in threaded connections, apply a sealant to the male threads. For plastic threads, apply a non-hardening, plastic-compatible sealant sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Water

- Maximum Temperature: 180° F

- Specifications Met: ASTM D4101, ASTM F1498

- Pipe Nipples and Pipe: Use Schedule 80 Polypropylene Plastic

- Flanges: Use Class 150 Polypropylene Plastic

Fittings with stainless steel collar have a reinforcement on the female threads to prevent the threads from cracking.

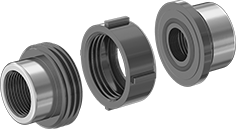

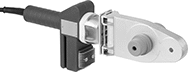

Unions separate into three pieces so you can access your line.

| Pipe Size | Material | Collar Material | O-Ring Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1/2 | Polypropylene Plastic | Stainless Steel | Viton® Fluoroelastomer Rubber | Black | 150 psi @ 72° F | 0000000 | 000000 |

| 3/4 | Polypropylene Plastic | Stainless Steel | Viton® Fluoroelastomer Rubber | Black | 150 psi @ 72° F | 0000000 | 00000 |

| 1 | Polypropylene Plastic | Stainless Steel | Viton® Fluoroelastomer Rubber | Black | 150 psi @ 72° F | 0000000 | 000000 |

| 1 1/2 | Polypropylene Plastic | Stainless Steel | Viton® Fluoroelastomer Rubber | Black | 150 psi @ 72° F | 0000000 | 000000 |

| 2 | Polypropylene Plastic | Stainless Steel | Viton® Fluoroelastomer Rubber | Black | 150 psi @ 72° F | 0000000 | 000000 |

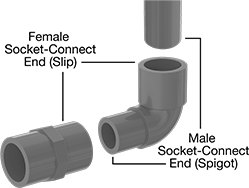

High-Purity Polypropylene Pipe Fittings for Corrosive Chemicals

The inside of these fittings won’t leach contaminants into your line or accumulate particles—they’re polished to an ultra-smooth 12 Ra finish, which also makes them easy to clean. Made of polypropylene, they resist organic solvents, acids, and alkalis better than CPVC fittings. These fittings meet NSF/ANSI 61 for use with drinking water, and they’re FDA compliant for direct contact with food. They also meet ASTM requirements for material and performance, and ISO requirements for dimensions.

Connect them to pipe with socket fusion welding for a strong, permanent bond. Use a socket fusion tool with a heater bushing (sold separately) that matches your pipe size.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

For technical drawings and 3-D models, click on a part number.

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Pipe Nipples and Pipe: Use SDR 11 Polypropylene Plastic

- Flanges: Use Polypropylene Plastic

Union connectors separate into three pieces, so you can access your line without unthreading pipe connections.

| Pipe Size | Socket Dp. | Material | Color | Max. Pressure | Each | |

EPDM Rubber O-Ring | ||||||

|---|---|---|---|---|---|---|

| 1/2 | 19/32" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 0000000 |

| 3/4 | 5/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | 45/64" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 15/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 2 | 1 1/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber O-Ring | ||||||

| 1/2 | 19/32" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 3/4 | 5/8" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 | 45/64" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 1 1/2 | 15/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

| 2 | 1 1/16" | Polypropylene Plastic | Light Gray | 150 psi @ 72° F | 00000000 | 000000 |

- For Use With: Deionized Water, Drinking Water, Hydrochloric Acid, Phosphoric Acid, Salt Water, Solvents

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2837, ASTM D4101, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 178.3297, ISO 7279, NSF/ANSI 61

- Seal Material: See table

- Seat Material: PTFE Plastic

Add a ball valve to control the flow in your line.

| Pipe Size | Flow Coefficient (Cv) | Vacuum Rating, in. of Hg | Port Type | End-to-End Lg. | Color | Max. Pressure | Each | |

EPDM Rubber Seal | ||||||||

|---|---|---|---|---|---|---|---|---|

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 0000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

Viton® Fluoroelastomer Rubber Seal | ||||||||

Polypropylene Plastic | ||||||||

| 1/2 | 12.5 | 29.92 | Full | 3 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 3/4 | 28 | 29.92 | Full | 4 9/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 | 50.9 | 29.92 | Full | 4 23/32" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 1 1/2 | 150 | 29.92 | Full | 6 1/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| 2 | 230 | 29.92 | Full | 6 13/16" | Light Gray | 150 psi @ 0° F | 00000000 | 000000 |

| Each | ||

| 00000000 | 0000000 |

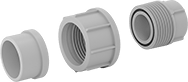

Gravity-Flow Polypropylene Pipe Fittings for Corrosive Chemical Waste

- For Use With: Deionized Water, Hydrochloric Acid, Oil, Phosphoric Acid, Salt Water, Solvents

- Maximum Temperature: 220° F

- Specifications Met: ASTM D4101, ASTM D635, ASTM F1412, UL 94 V-2

- Compatible with Gravity-Flow Polypropylene Pipe for Corrosive Chemical Waste

Made of polypropylene, these gravity-flow fittings withstand organic solvents, such as acetone, that would dissolve CPVC pipe. They also stand up to highly corrosive acids, such as hydrochloric acid, and alkalies. All meet UL and ASTM standards for flame retardance and self-extinguishment in the case of fire. They also meet strict ASTM specifications and testing requirements for material quality and product dimensions. They’re compatible with Orion Blueline No-Hub and Orion Rionfuse chemical waste pipe and pipe fittings.

270° bend connectors are also known as P-traps. Union connectors separate into three pieces for easy access to your line.

For technical drawings and 3-D models, click on a part number.