Filter by

For Use With

Maximum Flow Rate

Power

Power Source

Flow Rate @ 10 Feet of Head

Maximum Temperature

Maximum Feet of Head

Current

Discharge Connection

Maximum Pressure

Housing Material

DFARS Specialty Metals

Priming Type

Facility and Grounds Maintenance

Safety Equipment

Fluid Handling

Measuring and Inspecting

Electrical

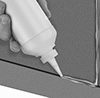

Sealing