About Plastic

More

Porous Mold-Quality Metapor Aluminum

- Yield Strength: Not Rated

- Hardness: Shore D80 (Soft)

- Temper: Not Rated

- Fabrication: Cast

Create molds for vacuum-forming and thermoforming applications. Metapor aluminum is porous to let air and moisture escape, which prevents bubbles and blemishes. These sheets must be milled to expose the pores; average pore diameter is 0.0006” with a total porosity of 15%.

For technical drawings and 3-D models, click on a part number.

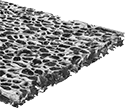

Lightweight Aluminum Foam

- Yield Strength: See table

- Hardness: Not Rated

- Fabrication: Cast

- Specifications Met: ASTM B557, ASTM E9

Air is injected into the casting of this aluminum to reduce weight and create a crater-like appearance. These foam sheets are often used for sound insulation and architectural facades. Carbide- or diamond-tipped blades are required for machining. Diamond-tipped blades will cut this material more easily and not wear down as quickly as carbide-tipped blades.

Small-cell foam is highly dense and stiff, so it’s ideal for building high-performance acoustic panels and sturdy decorative elements with a fine, detailed texture. It’s one-sixth the weight of solid aluminum.

Large-cell foam is lightweight due to its low density. It’s one-third the weight of small-cell foam and about 5% the weight of solid aluminum. Since it allows some light through, you can use it to build architectural light diffusers. This foam has the appearance of an aluminum sponge.

For technical drawings and 3-D models, click on a part number.

Porous PTFE Film

- Color: White

- Maximum Temperature: 500° F

- Specifications Met: UL 746C, UL 94 V-0

Shield vents on electronic and automotive equipment, such as cell phone microphones, from water, dirt, and debris without blocking them entirely. This film has tiny holes to let air, gas, and vapors pass through. Because it’s made of PTFE, it wicks away water. It also won’t react with most chemicals, though it can break down from alkali metal and high-temperature fluorinated agents. IP rated, this film stands up to dust, weather, washdowns, and even brief submersion.

For technical drawings and 3-D models, click on a part number.

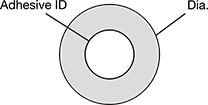

Porous PTFE Adhesive-Back Discs

- Color: White

- Maximum Temperature: 250° F

Stick these discs onto breather and other circular vents to guard against water and dirt without obstructing flow. Often used in the electronic and automotive industries, they have very small holes so air, gas, and vapor can still pass through. These discs are made of PTFE to wick water away. They also won’t break down from most chemicals, except alkali metal and high-temperature fluorinated agents.

IP rated except for their adhesive, all seal out dust and stand up to some submersion. IP65-rated discs also handle low-pressure washdowns, while IP66-rated discs withstand high-pressure washdowns.

Adhesive | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Thickness | Overall Thickness | Removes Particle Size Down To, microns | Airflow @ Surface Area | ID | Location | Type | Thickness | Environmental Rating | Pkg. Qty. | Pkg. | |

Small Pack | |||||||||||

1/2" Diameter | |||||||||||

| 0.007" | 0.015" | 0.4 | 0.28 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP67 | 50 | 0000000 | 000000 |

| 0.01" | 0.018" | 0.1 | 0.01 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP66, IP68 | 50 | 0000000 | 00000 |

| 0.01" | 0.018" | 0.1 | 0.09 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP65, IP68 | 50 | 0000000 | 00000 |

Large Pack | |||||||||||

1/2" Diameter | |||||||||||

| 0.007" | 0.015" | 0.4 | 0.28 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP67 | 100 | 0000000 | 00000 |

| 0.01" | 0.018" | 0.1 | 0.01 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP66, IP68 | 100 | 0000000 | 000000 |

| 0.01" | 0.018" | 0.1 | 0.09 cfm @ 1 sq. in. | 9/32" | Edge | Acrylic | 0.008" | IP65, IP68 | 100 | 0000000 | 00000 |

Porous Conductive Carbon

- Color: Gray

- Max. Temperature: 600° F

- Tensile Strength: See table

- Electrical Properties: Conductive

- Surface Resistivity: See table

Often used in filtering, this brittle, glass-like carbon has pores that allow fluid and air to flow through. Its low surface resistivity also makes it a good electrical conductor. This material is also temperature and chemical resistant.

For technical drawings and 3-D models, click on a part number.

3" × 3" | 6" × 6" | ||||||

|---|---|---|---|---|---|---|---|

| Thick. | Tensile Strength, psi | Surface Resistivity | Texture | Each | Each | ||

Low Flow (100 Pores Per Inch) | |||||||

| 1/4" | 50 | 7.87 × 10-2 ohms/sq. | Coarse | 00000000 | 000000 | 00000000 | 000000 |

| 1/2" | 50 | 3.94 × 10-2 ohms/sq. | Coarse | 00000000 | 00000 | 00000000 | 000000 |

| 1" | 50 | 1.96 × 10-2 ohms/sq. | Coarse | 00000000 | 000000 | 00000000 | 000000 |

Medium Flow (60 Pores Per Inch) | |||||||

| 1/4" | 40 | 7.87 × 10-2 ohms/sq. | Coarse | 00000000 | 00000 | 00000000 | 00000 |

| 1/2" | 40 | 3.94 × 10-2 ohms/sq. | Coarse | 00000000 | 00000 | 00000000 | 000000 |

| 1" | 40 | 1.96 × 10-2 ohms/sq. | Coarse | 00000000 | 000000 | 00000000 | 000000 |

High Flow (20 Pores Per Inch) | |||||||

| 1/4" | 30 | 7.87 × 10-2 ohms/sq. | Coarse | 00000000 | 00000 | 00000000 | 00000 |

| 1/2" | 30 | 3.94 × 10-2 ohms/sq. | Coarse | 00000000 | 00000 | 00000000 | 000000 |

| 1" | 30 | 1.96 × 10-2 ohms/sq. | Coarse | 00000000 | 000000 | 00000000 | 000000 |

High-Temperature Acid-Resistant Silicon-Carbide Ceramic Foam

- Color: Gray

- Maximum Temperature: 3,000° F

- Compressive Strength: 200 psi

A silicon carbide coating over a carbon foam base combines the hardness, chemical resistance, and high temperatures silicon carbide is known for with the lightweight versaitility of foam. It’s often used for cores in composite layers and to filter molten metal and corrosive liquids.

The silicon carbide coating acts as a thermal conductor, transferring heat to quickly cool liquids that pass through. Known for its hardness, silicon carbide won’t break down from repeated abrasion. However, because it’s so hard, this material is more brittle than plain carbon foam and less impact resistant than balsa wood, PET, and PVC foam cores.

Acids and bases can’t penetrate the silicon carbide coating, even at high temperatures. Instead, contaminants stick to the surface, making it a great filter for corrosive liquids and environmental pollutants such as exhaust. If using this material as a filter, choose a foam with more pores per inch for a slower flow rate, and a foam with fewer pores per inch for a faster flow rate.

If you cut this material, the underlying carbon foam is exposed. Carbon foam does not have the temperature range and chemical resistance of its silicon carbide coating, so it will break down more quickly at exposed points.

For technical drawings and 3-D models, click on a part number.

3" × 3" | 6" × 6" | |||||

|---|---|---|---|---|---|---|

| Thickness | Thickness Tolerance | Pores Per Inch | Each | Each | ||

| 1/8" | -0.010" to 0.010" | 60 | 00000000 | 0000000 | 00000000 | 0000000 |

| 1/8" | -0.010" to 0.010" | 100 | 00000000 | 000000 | 00000000 | 000000 |

| 1/4" | -0.010" to 0.010" | 20 | 00000000 | 000000 | 00000000 | 00000000 |

| 1/4" | -0.010" to 0.010" | 60 | 00000000 | 000000 | 00000000 | 00000000 |

| 1/4" | -0.010" to 0.010" | 100 | 00000000 | 000000 | 00000000 | 00000000 |